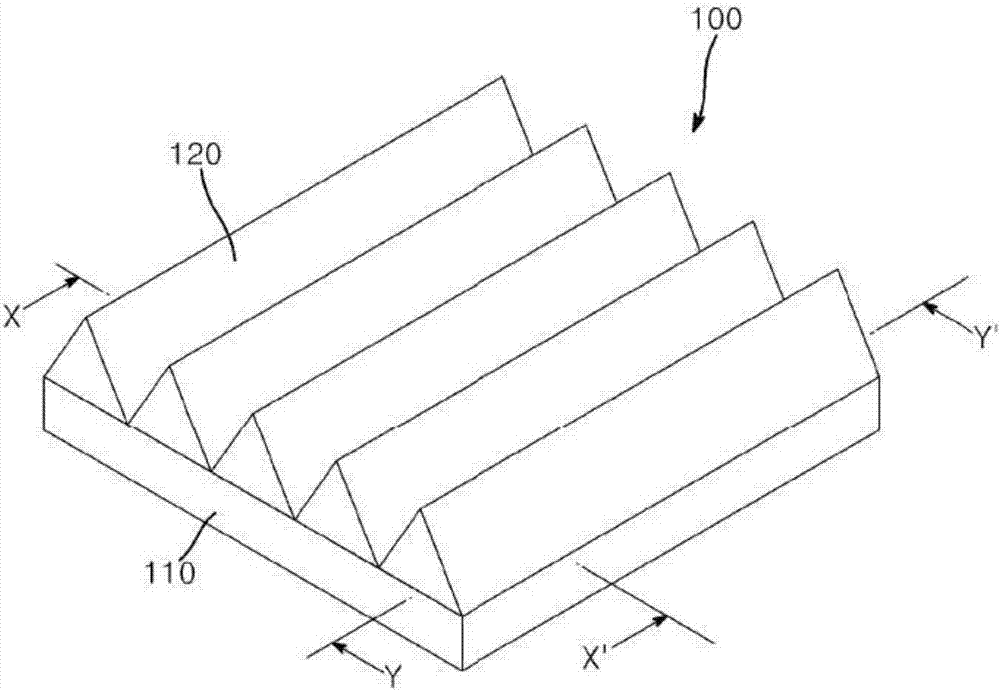

Optical sheet, and polarizing plate and liquid crystal display comprising same

A technology for optical sheets and polarizers, applied in optics, nonlinear optics, instruments, etc., to solve problems such as difficulty in realizing slender or thin-thickness electronic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

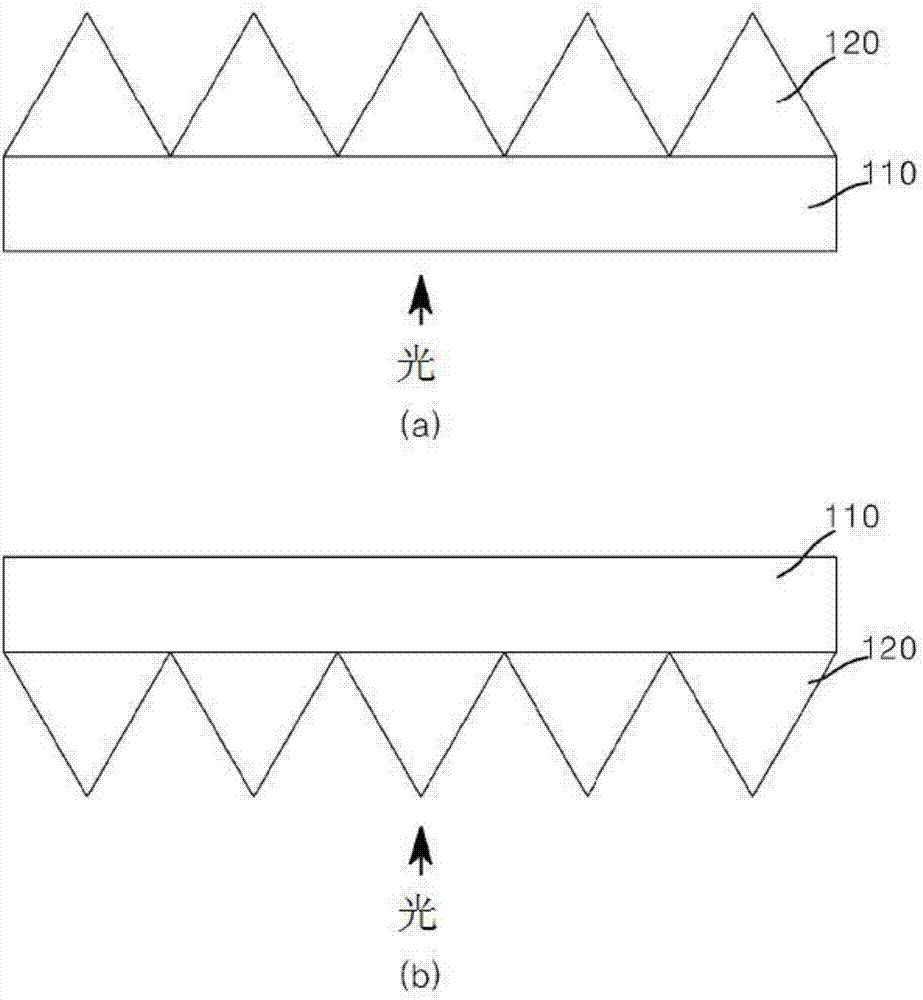

Method used

Image

Examples

example 1 and example 2 and comparative example 1 to comparative example 4

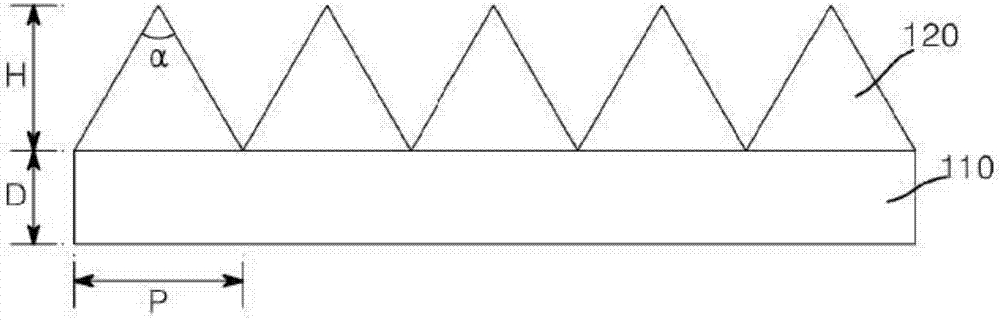

[0137] Example 1 and Example 2 and Comparative Example 1 to Comparative Example 4: Preparation of Optical Sheets

example 1

[0139] A photocurable resin composition comprising: 70% by weight of acrylate resin (TBP102, Hannong Chemical Co., Ltd. Co., Ltd.), 5% by weight of phenoxybenzyl acrylate, 7% by weight of bisphenol F acrylate, 10% by weight of ethoxylated sulfur diphenyl diacrylate, 1% by weight of ester acrylate (ECX 5031, Corning Co., Ltd.), 2% by weight of antistatic agent (HR-E, Nano Chemical Technology Co., Ltd.), 1% by weight of silicon additive (UV-3530, BYK company) and 4% by weight of initiator agent (Irgacure 184, Irgacure TPO, Ciba Chemical Co., Ltd.). When one surface of the base film (polyethylene terephthalate film, Toyobo Co., Ltd.) of Table 1 was brought into contact with the composition layer on the mold, the coated composition was cured by irradiating with ultraviolet light to form a coating. Floor. Subsequently, the coating layer bonded to the base film was separated from the mold, thereby preparing an optical sheet having a light collection pattern layer on one surface of...

example 2

[0142] An optical sheet was prepared in the same manner as in Example 1, except that the height, pitch, and apex angle of the unit prisms constituting the light-collecting pattern layer were changed as listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com