Pump unit for feeding fuel, preferably diesel fuel, to an internal combustion engine

A pump unit, internal combustion engine technology, applied in the direction of fuel injection pumps, components of pumping devices for elastic fluids, liquid fuel engines, etc., can solve the problems of costly precision machining operations, wear and sealing, and achieve easy threaded connections Realize, reduce friction and wear points, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

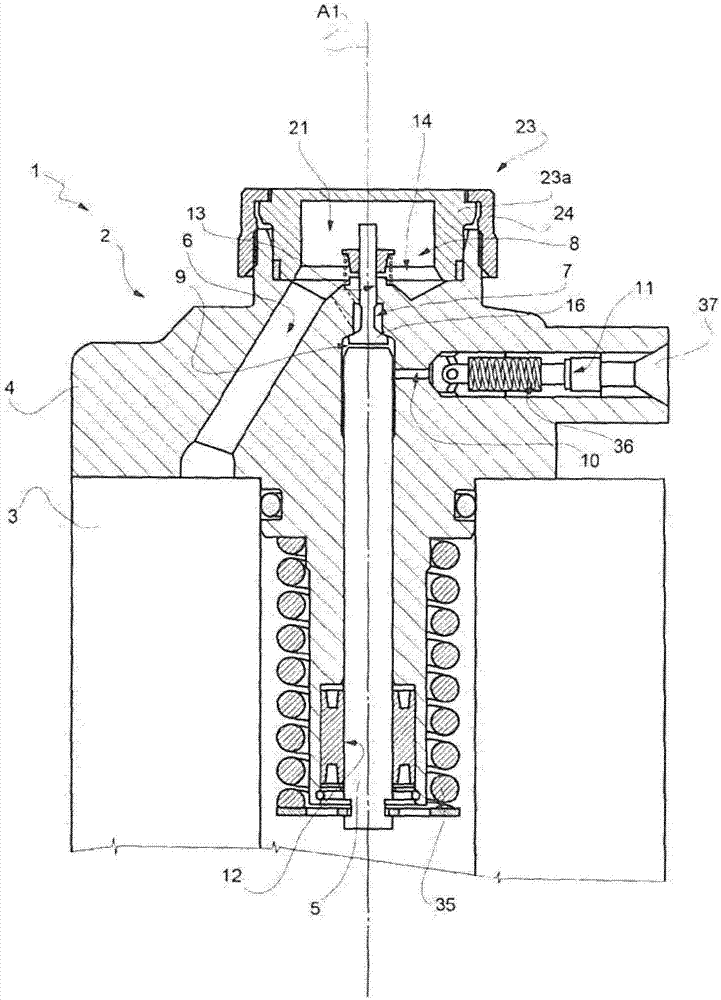

[0039] refer to figure 1 and figure 2 , reference number 1 designates as a whole a pump unit for supplying fuel, preferably diesel, to an internal combustion engine (not shown).

[0040] The pump unit 1 comprises: a high-pressure pump 2 of the pumping piston type, designed to supply fuel to said internal combustion engine (not shown); and a known gear pump (not shown), which Designed to feed fuel to pump 2. The pump 2 and the gear pump are driven by shafts (not shown in the figures).

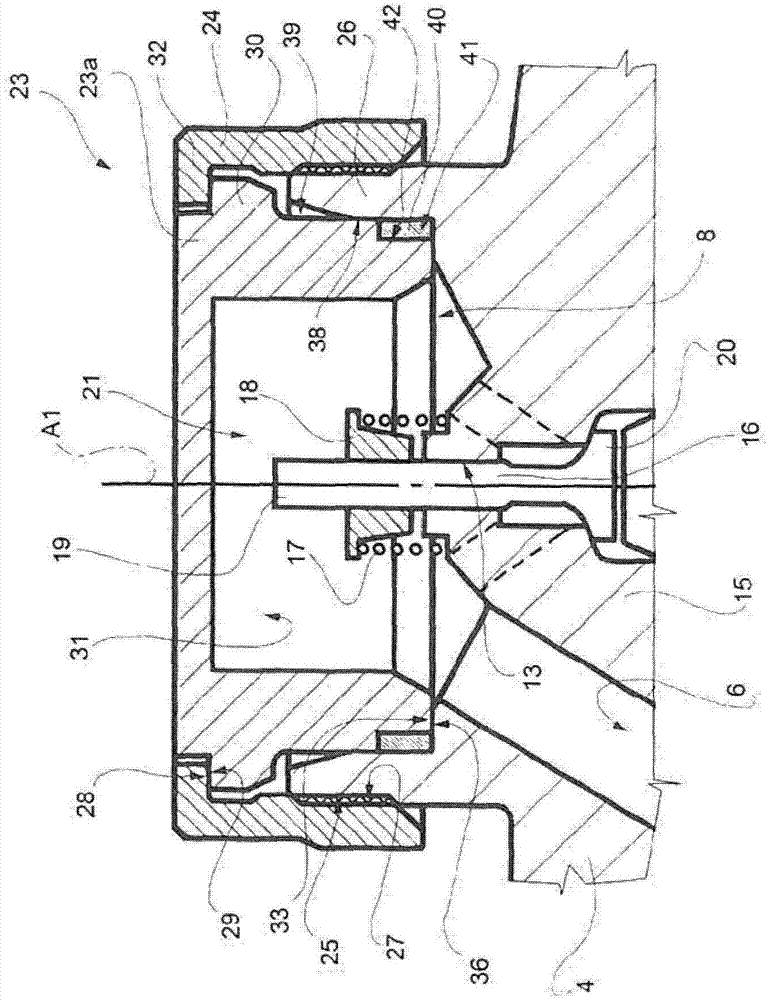

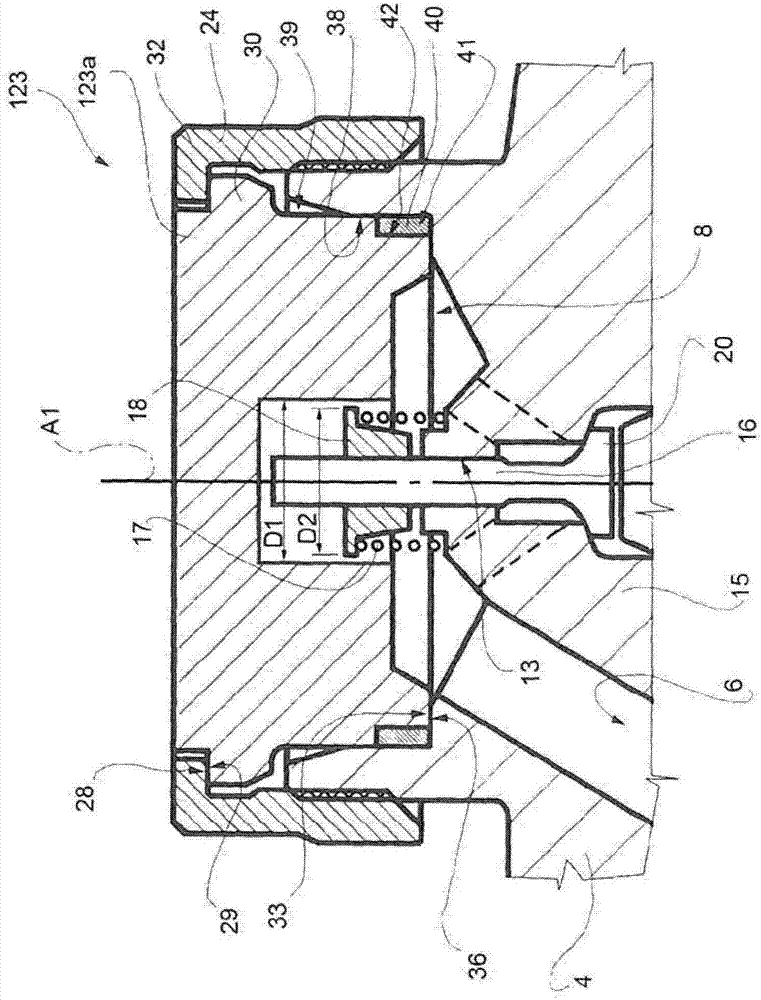

[0041] The pump 2 comprises: a pump body 3; a head 4 assembled on the pump body 3; a cylinder 12 formed in the head 4 and extending along the axis A1; a pumping piston 5 extending along the axis A1, And with the cylinder 12 slidingly coupled; feed pipe 6, which is partially formed in the head 4; feed valve 7, which communicates with the feed pipe 6; feed chamber 8, which is arranged in the feed pipe 6 and the inlet valve 7; the compression chamber 9, which communicates with the inlet chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com