Polyester film for optical use and polarizing plate using same

A technology of polyester film and optics, applied in optics, optical elements, polarizing elements, etc., can solve the problems of increased thermal shrinkage, whitening, high retardation, etc., and achieves the effect of excellent whitening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

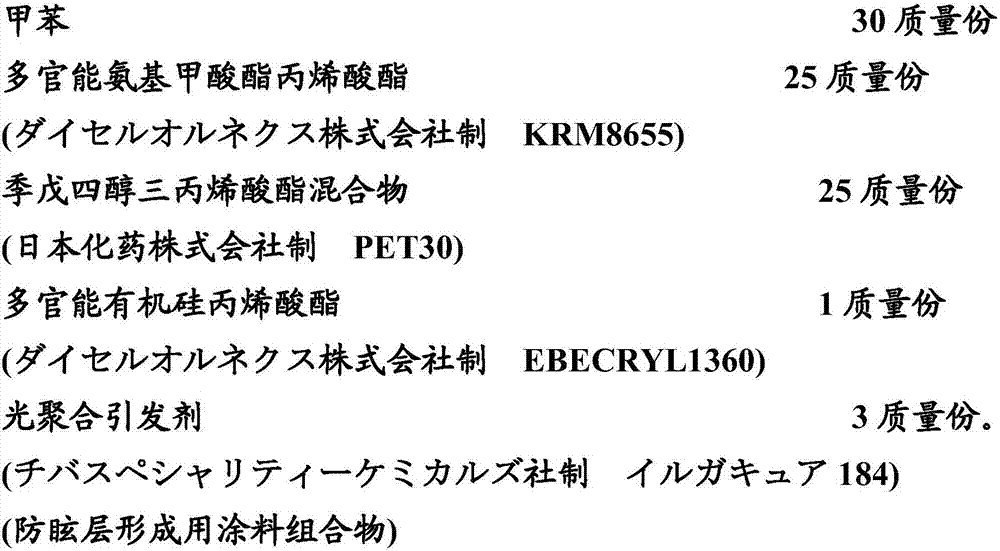

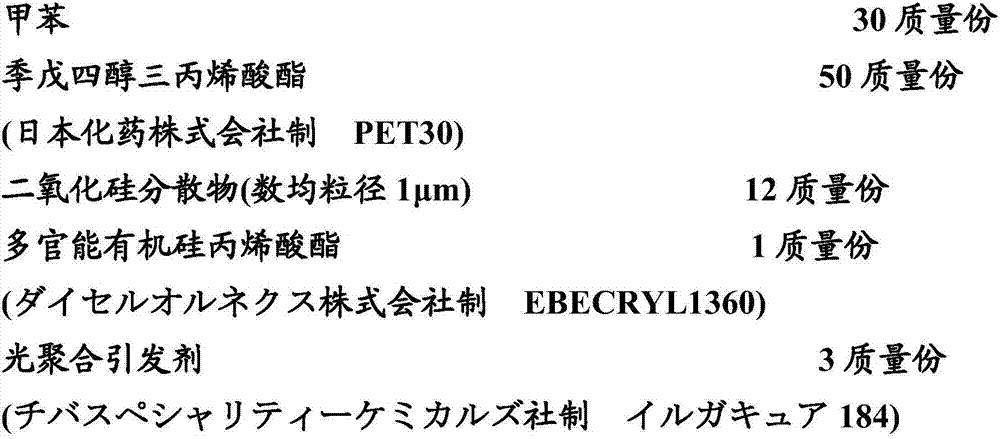

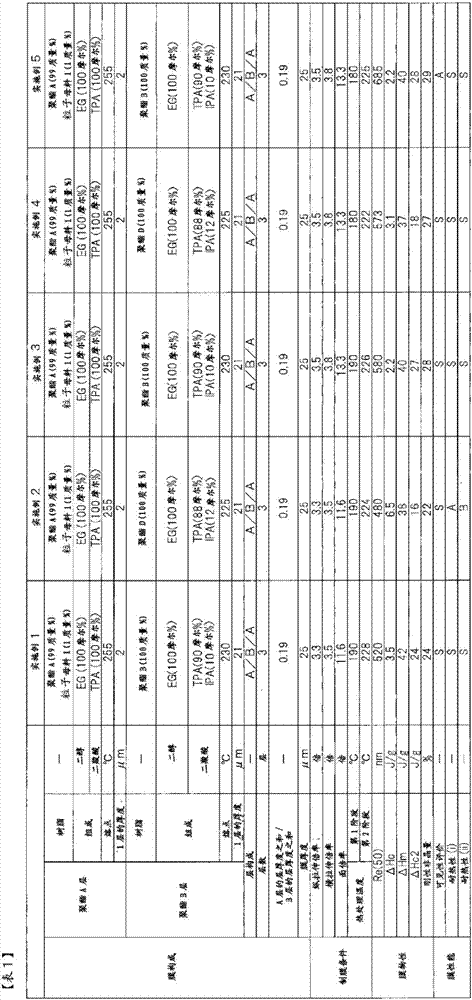

[0162] Make the composition as shown in the table, supply the raw materials to separate exhaust co-direction twin-screw extruders with the oxygen concentration set to 0.2% by volume, set the barrel temperature of the layer A extruder to 280°C, and extrude the layer B The barrel temperature of the machine is 265°C for melting, and in the feeding area, it is combined in a manner of forming three layers of A layer / B layer / A layer, so that the temperature of the short tube after confluence is 270°C, and the die temperature is The temperature is 275°C, and the sheet is discharged from the T-die onto the cooling drum whose temperature is controlled at 25°C. At this time, static electricity was applied using a wire-shaped electrode with a diameter of 0.1 mm, and it was brought into close contact with a cooling drum to obtain an unstretched sheet. Next, it was preheated for 1.5 seconds at a preheating temperature of 85°C in the longitudinal direction, stretched 3.3 times in the longit...

Embodiment 2

[0164] Except having changed the composition as shown in a table|surface, it carried out similarly to Example 1, and obtained the biaxially-oriented polyester film of thickness 25 micrometers.

Embodiment 3

[0166] The draw ratio in the longitudinal direction is set to 3.5 times, the draw ratio in the width direction is set to 3.8 times, the heat treatment temperature in the first stage is set to 190°C, and the heat treatment temperature in the second stage is set to 228°C. 1 In the same manner, a biaxially oriented polyester film with a thickness of 25 μm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com