Functional film, sound-insulating glass comprising glass having said functional film bonded thereto, laminated glass, base member for decorative film, and method for producing functional film

A technology of functional film and manufacturing method, applied in glass/slag layered products, other household appliances, chemical instruments and methods, etc., can solve problems such as uneven existence, and achieve the effect of excellent adhesion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0336] Example 1

[0337] "Making of Functional Film 101"

[0338] 〔Preparation of mucilage〕

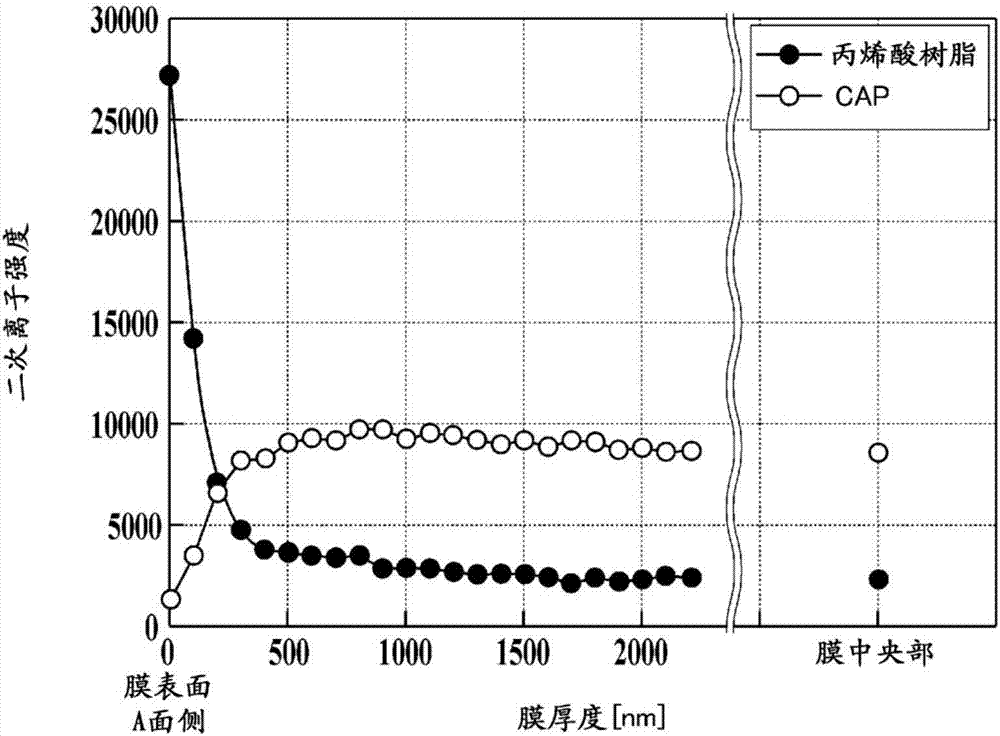

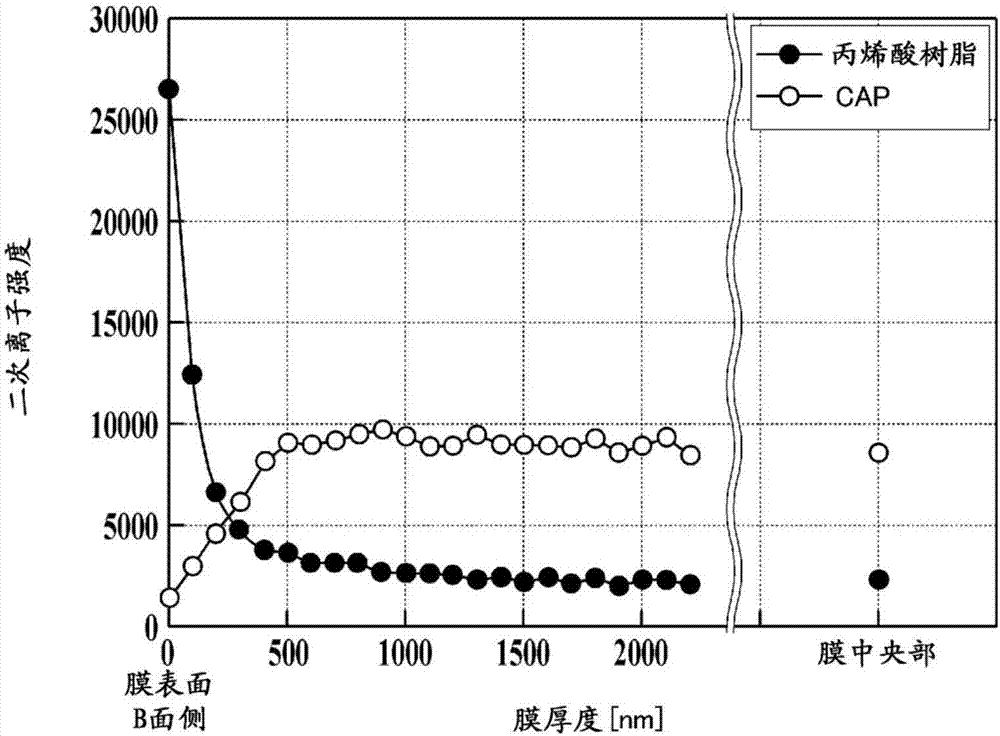

[0339] A cement of the following composition was prepared. First add dichloromethane and ethanol in a pressurized dissolving tank. An acrylic resin as resin 1 and CAP (cellulose acetate propionate) as resin 2 were charged into a pressurized dissolving tank containing a mixed solution of methylene chloride and ethanol while stirring. Heat it up and dissolve it completely while stirring. This was filtered using Azumi filter paper No. 244 manufactured by Azumi Filter Paper Co., Ltd., to prepare a main dope.

[0340] Acrylic resin (copolymer of methyl methacrylate: methyl acrylate = 97:3 (mass ratio), weight average molecular weight 280000) 30 parts by mass

[0341] CAP (weight average molecular weight 200000, total acyl substitution degree 2.75, acetyl substitution degree 0.19, propionyl substitution degree 2.56) 70 parts by mass

[0342] ME (solvent) 400 parts by mass

[0343] P...

Embodiment 2

[0379] "Making of Functional Films 201~208, 210~217"

[0380] In the making of the functional film 101 of Example 1, triethylene glycol bis(2-ethylhexanoate) (manufactured by Proviron Corporation) (abbreviated as HBS1 in the table) as HBS was used in the preparation of the main glue. ) and the type and amount of the resin were changed as shown in Table 2, and then, the functional films 201 to 208 and 210 to 217 were produced in the same manner as the production of the functional film 101 .

[0381] "Making of Functional Film 209"

[0382] In the production of the functional film 204, 2.5 parts by mass of the following UV1 as a benzotriazole-based ultraviolet absorber was further added to the preparation of the main dope, and the functional film 204 was made in the same manner as the functional film 204 except that Film 209.

[0383] UV1: Tinuvin 928 (manufactured by BASF Japan Co., Ltd.)

[0384] "Evaluation of Functional Films 201-217"

[0385] (Stress at elongation)

[...

Embodiment 3

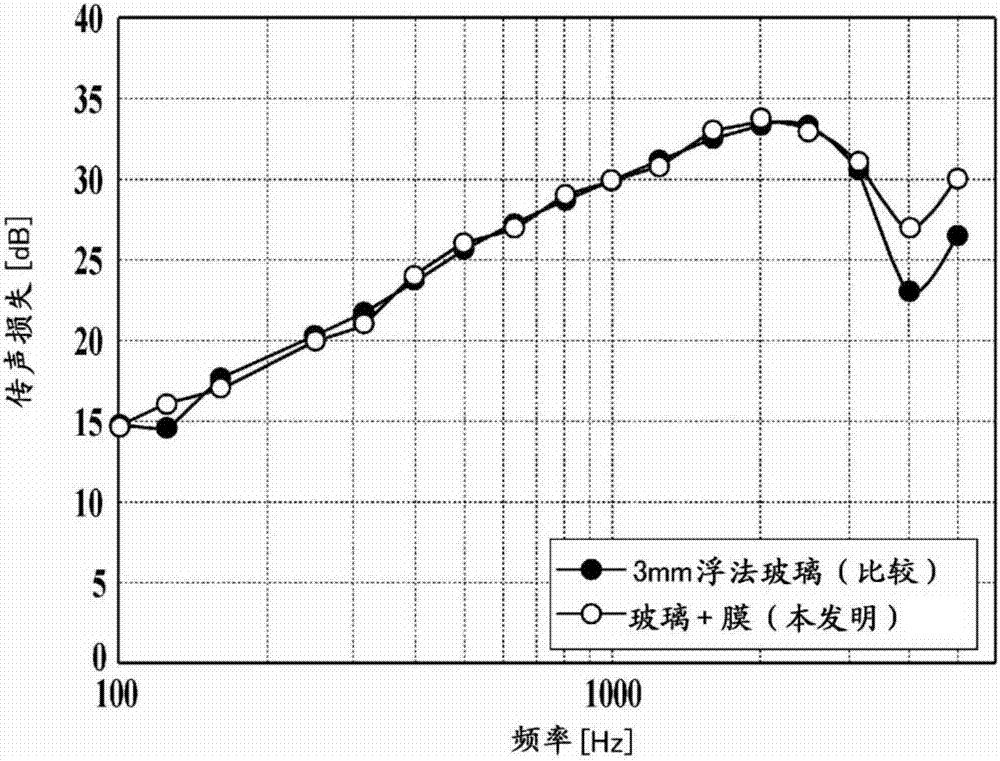

[0412] Using the functional films 201 to 217 prepared in Example 2, a film having an adhesive layer on both sides was sandwiched between two transparent float glasses (manufactured by Nippon Sheet Glass Co., Ltd.) with a thickness of 3.0 mm, and the films were laminated using a vacuum laminator. Hold at 90 degreeC for 30 minutes, perform vacuum pressing, and manufacture the laminated glass 301-317 bonded to two sheets of float glass. The adhesive layer used an adhesive acrylic adhesive (Nissetsu SZ-7103, manufactured by Nippon Carbide) in the same manner as in Example 2, and was applied so as to have a film thickness of 9 μm after drying.

[0413] For laminated glasses 301 to 317, the sound insulation is judged based on the difference (dB) between the comparison glass and the laminated glass in the overlapping region (2000 Hz) generated in the float glass, that is, the sound transmission loss increase value, as follows Grading.

[0414] ◎: The sound transmission loss improvem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Martens hardness | aaaaa | aaaaa |

| Martens hardness | aaaaa | aaaaa |

| Martens hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com