Connector assembly with at least one connector and at least one media line

A technology of connector components and medium pipes, applied in the direction of pipes/pipe joints/fittings, couplings, heating elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

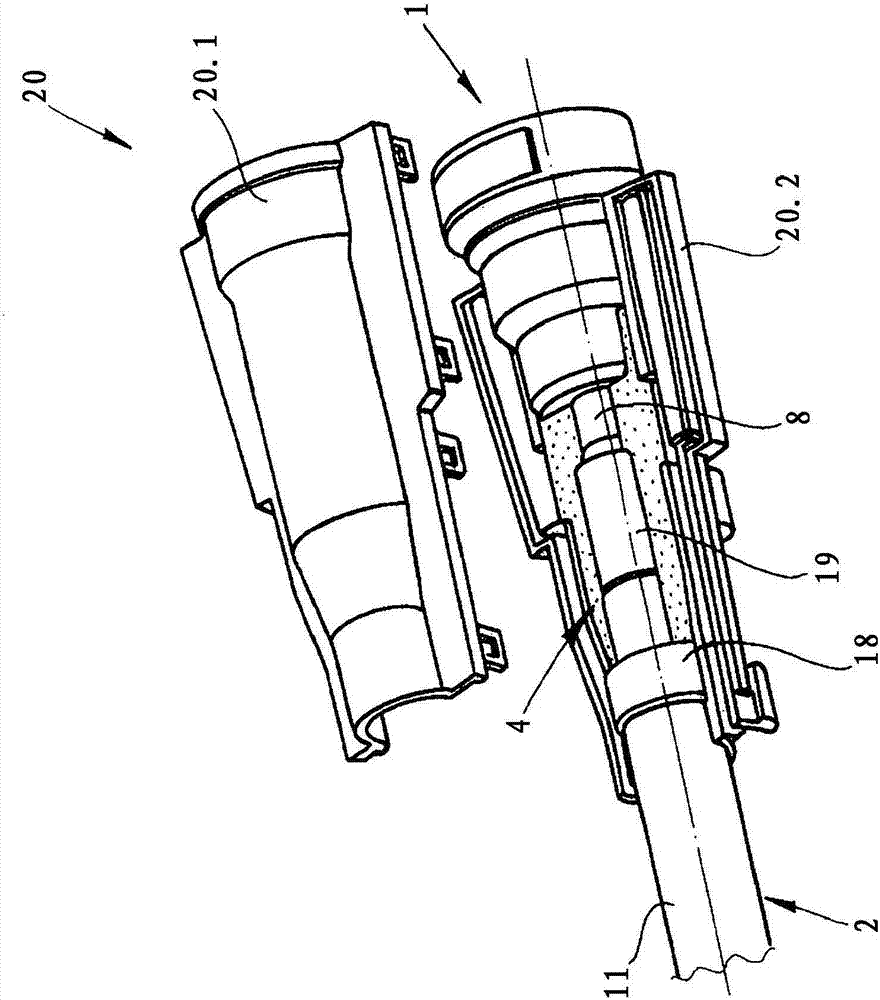

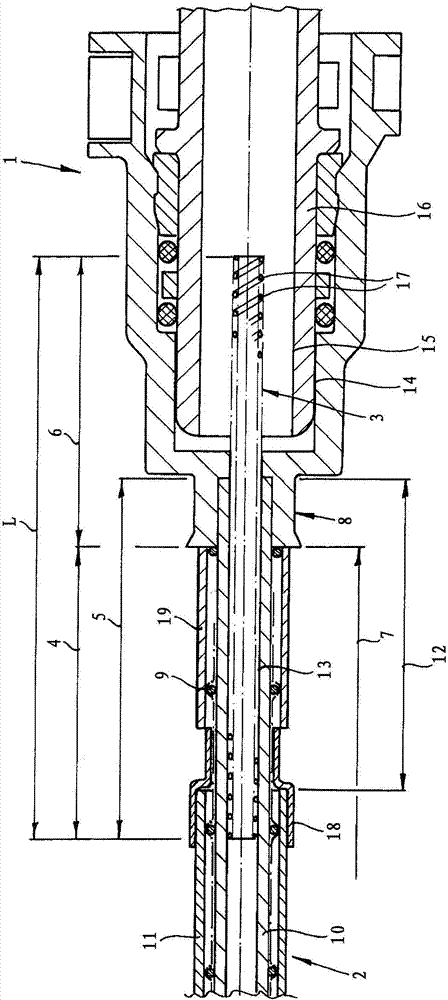

[0024] The drawing shows a connector assembly according to the invention, which is preferably and in the exemplary embodiment designed as a motor vehicle connector assembly, comprising a connector 1 in the form of a quick connector and a medium line 2 connected thereto. The connector assembly is used in particular for the transmission of fluid media of the motor vehicle, more precisely for the transmission of an aqueous urea solution for the catalyst system of the motor vehicle. According to a preferred embodiment and in this example the medium line 2 is heated electrically, ie by means of a heating wire 9 wound helically around the inner tube 10 of the medium line 2 .

[0025] The heat-conducting element 3 according to the invention is arranged in the transition region 4 between the connector 1 and the medium line 2 . The heat-conducting element 3 extends by means of a first heat-conducting section 5 into the medium line 2 and by means of a second heat-conducting section 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com