Space lattice material based on curved bar base cells

A space lattice and cell technology, applied in building materials, building components, earthquake-proof and other directions, can solve the problems of difficulty in meeting, low impact energy absorption rate, poor impact deformation ability, etc., to expand the scope of application and improve the absorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

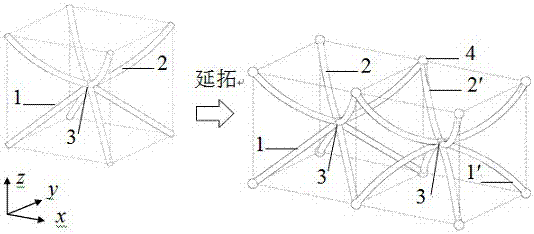

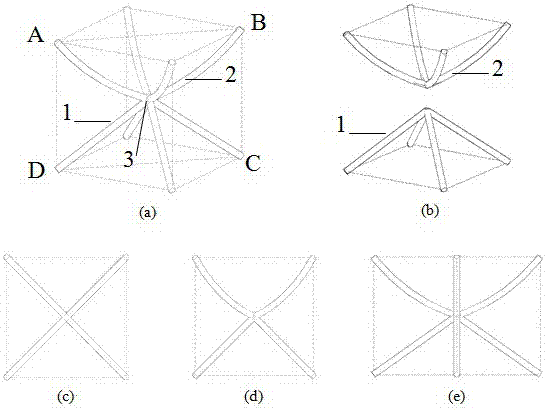

Method used

Image

Examples

Embodiment 1

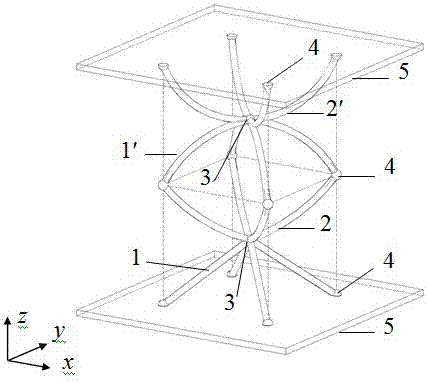

[0030] Embodiment 1: as image 3 As shown, the curved rod of the cell is a steel member, and the cell is connected to the steel plate (5) through the outer node (4) of the cell after being extended in the z direction. The cell extension curved rods (1′) and (2′) in the figure are only for illustration, the cells can be extended along the x, y, z directions, and the number N of lattice material cells can be determined as required. The curvature of each group of curved rods in the cell changes according to a certain gradient in a certain direction, and the curvature of each group of curved rods in each cell along the x, y, z directions also changes according to a certain gradient, In this way, the stiffness (deformation characteristics) in different directions can be changed gradually. This structure can realize the impact resistance of the surface of the lattice material and the strong deformation and energy absorption function inside the lattice material.

Embodiment 2

[0031] Embodiment 2: as Figure 4 As shown, the curved rod of the cell is a steel member, and the cell is connected to the planar steel grid frame (6) through the outer node (4) of the cell after being extended in the z direction. The cell extension curved rods (1′) and (2′) in the figure are only for illustration, the cells can be extended along the x, y, z directions, and the number N of lattice material cells can be determined as required. The curvature of each group of curved rods in the cell changes according to a certain gradient in a certain direction, and the curvature of each group of curved rods in each cell along the x, y, z directions also changes according to a certain gradient, In this way, the stiffness (deformation characteristics) in different directions can be changed gradually. This structure can realize the smooth surface of the lattice material and the interior of the lattice material has a strong deformation and energy absorption function.

Embodiment 3

[0032] Embodiment 3: as Figure 5 As shown, the curved rod of the cell is a steel member, and the cell is extended in the z direction and connected with the planar steel grid frame (6) and the concrete slab (7) through the outer node (4) of the cell. The cell extension curved rods (1′) and (2′) in the figure are only for illustration, the cells can be extended along the x, y, z directions, and the number N of lattice material cells can be determined as required. The curvature of each group of curved rods in the cell changes according to a certain gradient in a certain direction, and the curvature of each group of curved rods in each cell along the x, y, z directions also changes according to a certain gradient, In this way, the stiffness (deformation characteristics) in different directions can be changed gradually. This structure can realize the impact resistance of the surface of the lattice material and the strong deformation and energy absorption function inside the latti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com