Transparent polyurethane composition with visible gelling characteristic and preparation method

A composition, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy peeling, poor water dispersibility, no protection and decorative performance, etc., to ensure construction quality, easy mixing and uniformity, high market The effect of practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

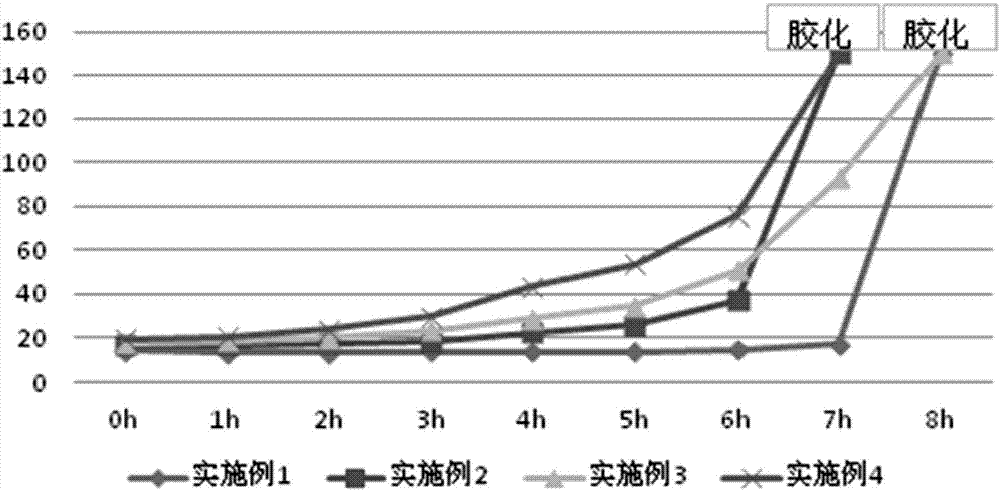

Examples

Embodiment 1

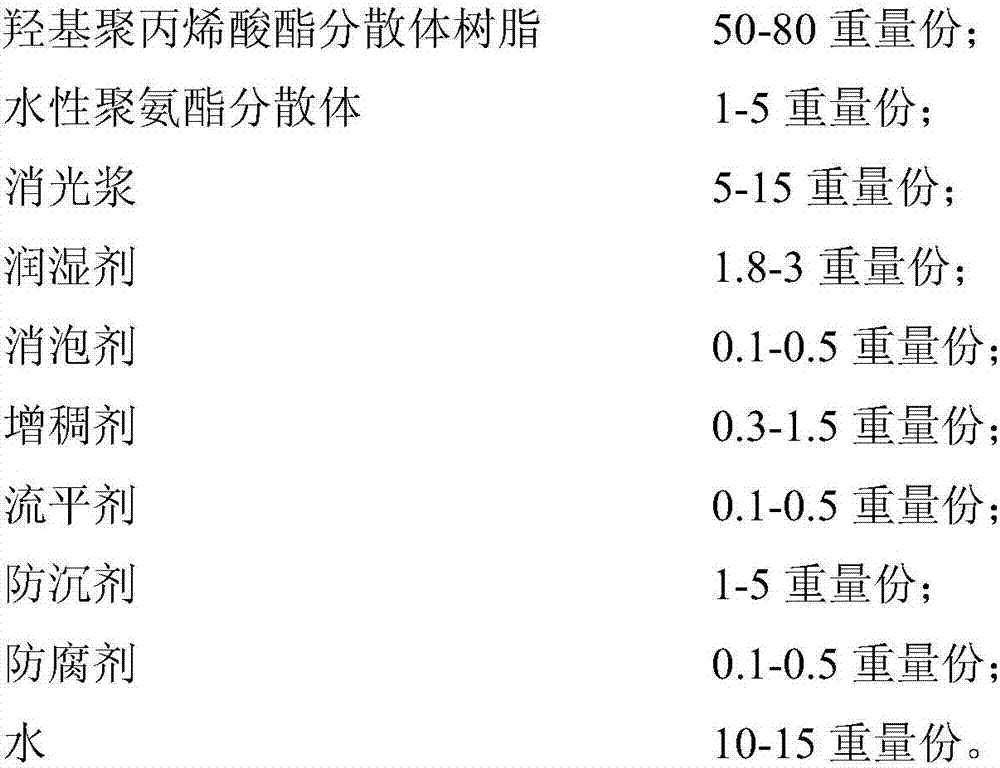

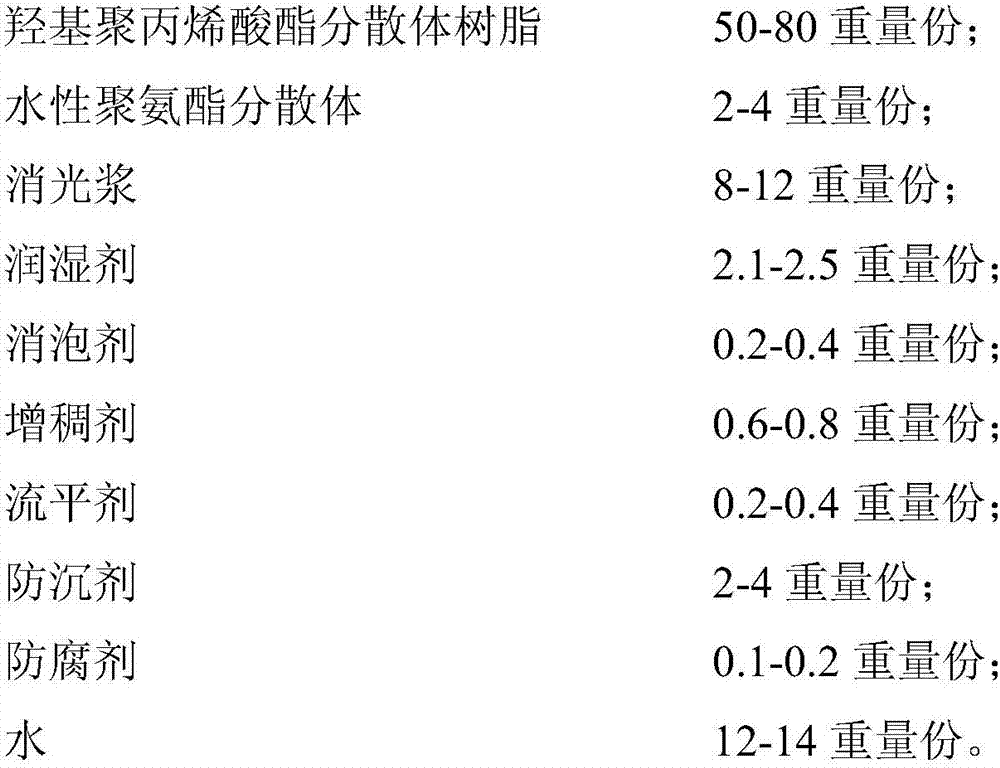

[0088] Prepare component A and component B according to the ingredients and weight percentages shown in Table 1.

[0089] Table 1 Components and percentage by weight

[0090]

[0091] a. Prepare the main paint of component A: first add hydroxyacrylate dispersion resin, polyurethane dispersion resin, and water with a total weight of 50% in the dispersion tank; carry out medium-speed dispersion at 600-650r / min; then slowly Add matting slurry; disperse at a high speed of 1000-1200r / min for 10-15 minutes, then add wetting agent, thickener, defoamer, leveling agent, anti-settling agent, preservative in the tank and the remaining water, medium speed After dispersing for 15-25 minutes, take a sample to test that the fineness of the finished product is in the range of 20-35um, the viscosity is in the range of 45-55KU, filter, fill in cans, and pack.

[0092] The matting pulp is a mixture of water, acrylic polymer dispersant EDAPLAN-480, organic amine pH regulator AMP-95, matting p...

Embodiment 2

[0096] Prepare component A and component B according to the ingredients and weight percentages shown in Table 1.

[0097] a. Preparation of component A main paint: first add hydroxyacrylate dispersion resin, polyurethane dispersion resin, and water with a total weight of 50% in the dispersion tank; carry out medium-speed dispersion at 650-800r / min; then slowly Add matting slurry; disperse at high speed of 1200-1500r / min for 10-15min, then add wetting agent, thickener, defoamer, leveling agent, anti-settling agent, preservative in the tank and the remaining water, medium speed After dispersing for 15-25 minutes, take a sample to test that the fineness of the finished product is in the range of 20-35um, the viscosity is in the range of 45-55KU, filter, fill in cans, and pack.

[0098] The matting pulp is a mixture of water, acrylic polymer dispersant EDAPLAN-480, organic amine pH regulator AMP-95, matting pulp defoamer TEGO Foamex 810, propylene glycol, fumed silica matting powd...

Embodiment 3

[0102] Prepare component A and component B according to the ingredients and weight percentages shown in Table 1.

[0103] a. Preparation of component A main paint: first add hydroxyacrylate dispersion resin, polyurethane dispersion resin, and water with a total weight of 50% in the dispersion tank; carry out medium-speed dispersion at 700-800r / min; then slowly Add matting slurry; disperse at a high speed of 1200-1400r / min for 10-15min, then add wetting agent, thickener, defoamer, leveling agent, anti-settling agent, preservative in the tank and the remaining water, medium speed After dispersing for 15-25 minutes, take a sample to test that the fineness of the finished product is in the range of 20-35um, the viscosity is in the range of 45-55KU, filter, fill in cans, and pack.

[0104] The matting pulp is a mixture of water, acrylic polymer dispersant EDAPLAN-480, organic amine pH regulator AMP-95, matting pulp defoamer TEGO Foamex 810, propylene glycol, fumed silica matting po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com