Waste heat desalinating system and desalinating method for ship

A desalination system and waste heat technology, applied in chemical instruments and methods, ship construction, ship parts, etc., can solve problems such as high energy consumption, inability to directly provide high-temperature hot water, and high requirements for working environment, achieve low energy consumption, and improve primary energy Utilization efficiency, the effect of improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

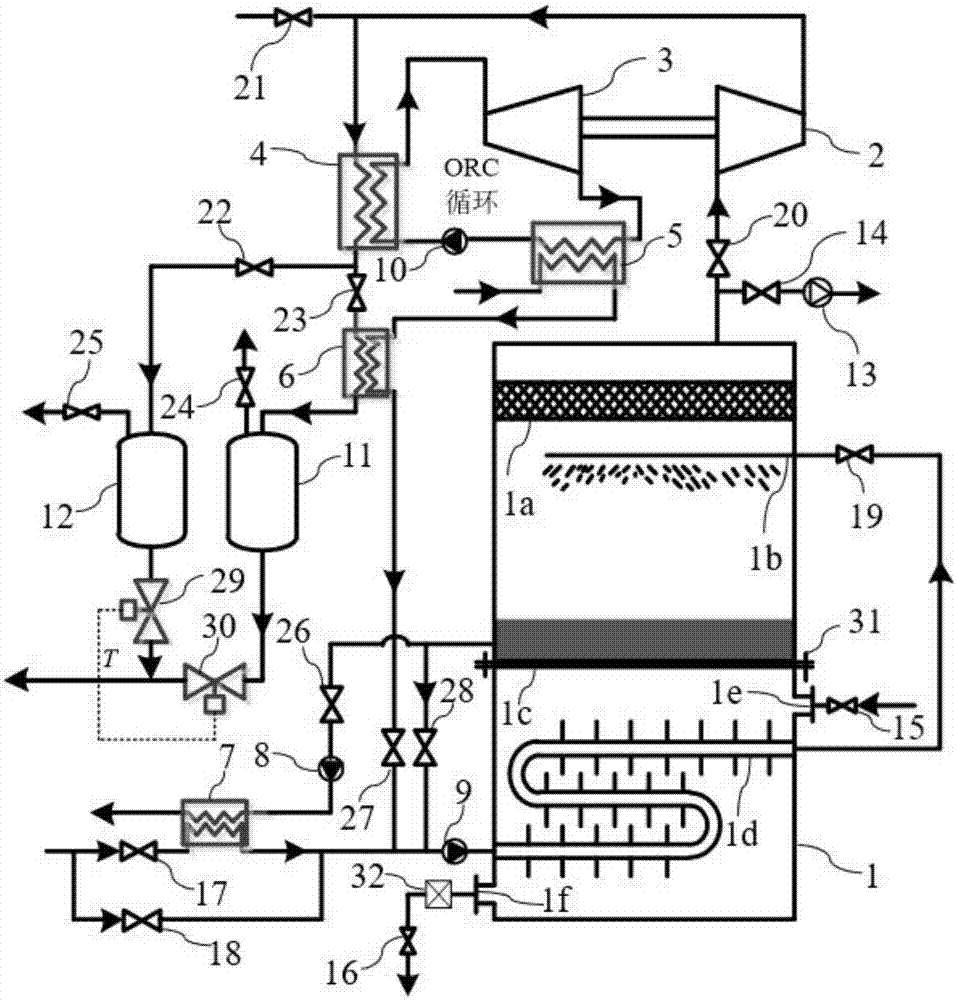

[0024] Such as figure 1 As shown, a ship waste heat desalination system includes a heat recovery steam generator 1, a steam compressor 2, an organic working fluid Rankine (ORC) cycle, a hot water tank 12, a cold water tank 11, and a hot water heat recovery heat exchanger 6 , drain heat recovery heat exchanger 7; the heat recovery steam generator 1 is divided into upper and lower parts by a sealing plate 1c, which are connected by connecting flanges and bolts 31, and the lower part is a flue gas heat recovery cavity, which contains a heat recovery chamber with wings Recycling heat exchange tube 1d, flue gas inlet 1e, flue gas outlet 1f, the flue gas inlet is provided with a first valve 15, the flue gas outlet is provided with a flue gas purifier 32 and a second valve 16 for discharge; the upper part is a steam generating chamber , including spray pipe 1b, filter screen 1a, top exhaust port and bottom drain port; spray pipe 1b is connected to the outlet of heat exchange tube 1d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com