Overhead rail pulley assembly for assembling streamline

An assembly line and component technology, which is applied in the direction of load-carrying blocks, load-hanging components, transportation and packaging, etc., can solve the problems of structural toughness, corrosion resistance, poor wear resistance, short service life, and easy to fall off, etc., so as to eliminate production safety Hidden danger, excellent corrosion resistance and wear resistance, and the effect of ensuring the stability of conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

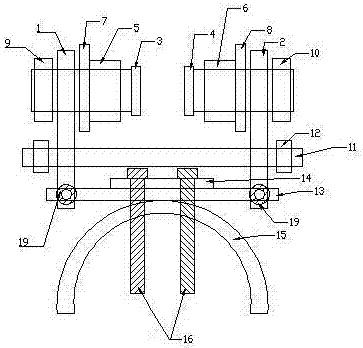

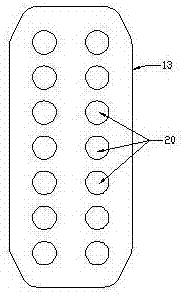

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 A suspension rail block assembly for assembly line assembly as shown, consists of a left support plate 1, a right support plate 2, and a set of first roller assemblies respectively arranged on the left support plate 1 and right support plate 2, and a set of second roller assemblies. The roller assembly, and the horizontal support connecting plate 13 respectively connected to the left support plate 1 and the right support plate 2, and the adjustment support assembly used in conjunction with the horizontal support connecting plate 13 are composed of the left support plate 1 and the right support plate 2. Holes 17 are correspondingly arranged respectively, and the horizontal support connecting plate 13 is connected with the left support plate 1 and the right support plate 2 through the holes 17; Screw rod 3, and the first roller 5 that is arranged on the first positioning screw rod 3, and the first adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com