Ceramic tile with heating function and preparation method thereof

A ceramic brick and functional technology, applied in ohmic resistance heating, ceramic layered products, chemical instruments and methods, etc., can solve the problems of poor thermal insulation effect, low thermal efficiency, easy heat loss, etc., to improve heating efficiency and thermal insulation performance. , strong operability, the effect of improving heating efficiency and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be specifically described below in conjunction with the embodiments, so that those skilled in the art can understand the present invention. It is necessary to point out here that the embodiments are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Those skilled in the art can make non-essential improvements and improvements to the present invention according to the above-mentioned content of the invention. Adjustment should still belong to the protection scope of the present invention. At the same time, if the raw materials mentioned below are not specified in detail, they are all commercially available products; the process steps or preparation methods not mentioned in detail are all process steps or preparation methods known to those skilled in the art.

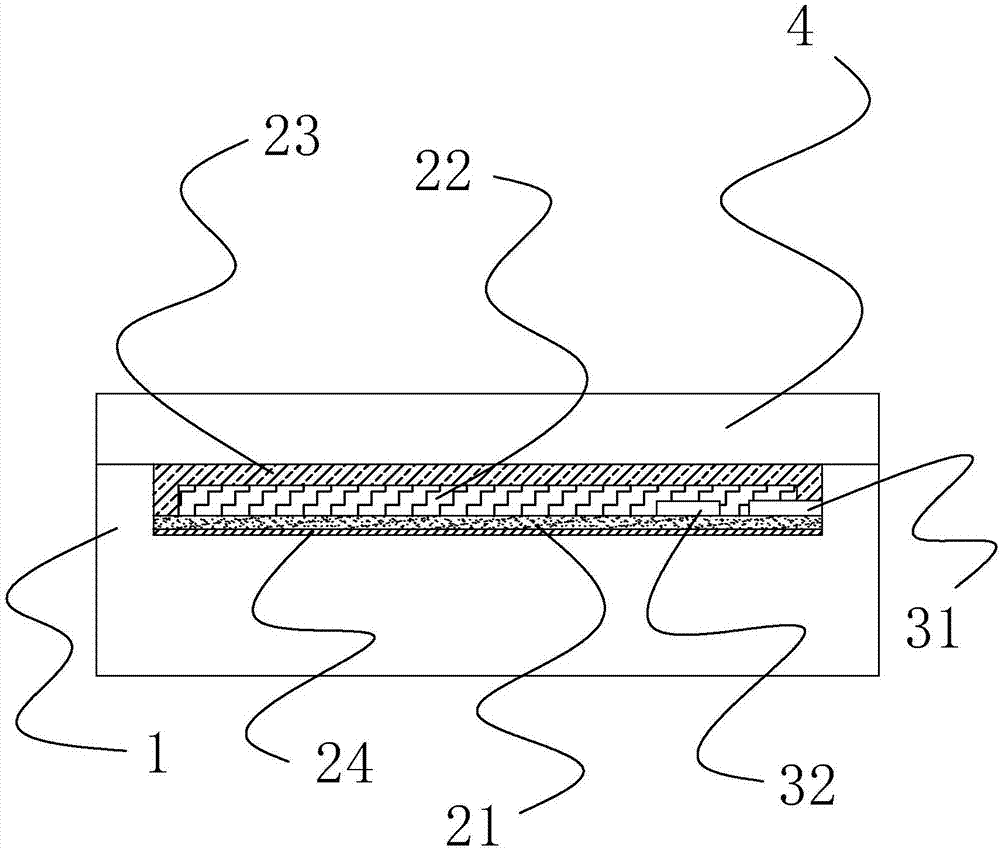

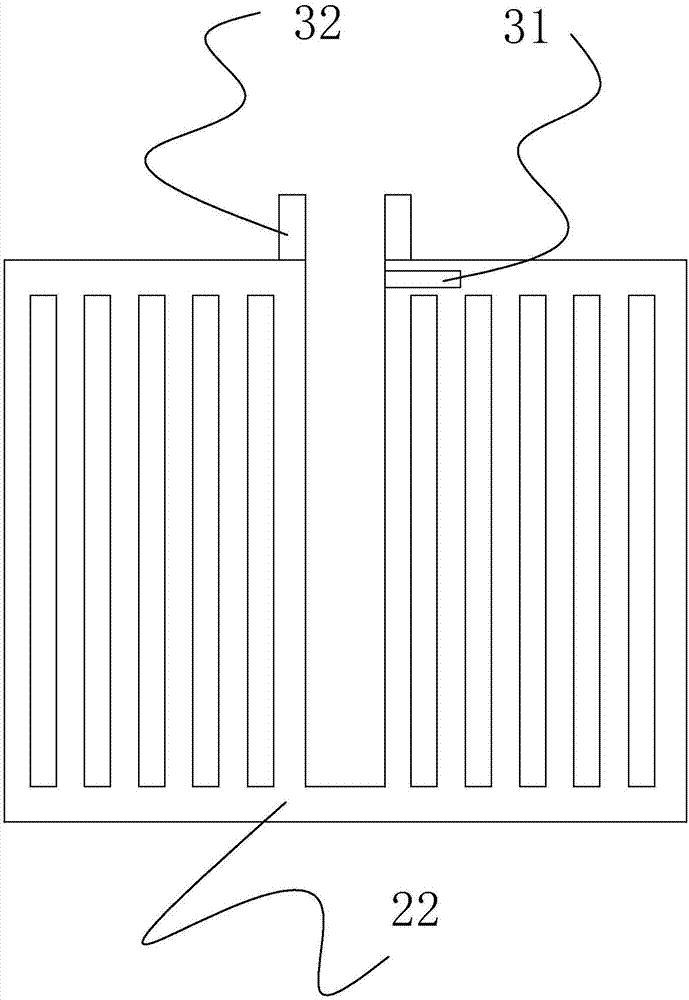

[0031] Refer to attached figure 1 , a ceramic tile with a heating function, which is formed by la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com