A method for testing the electromigration of butt joints with consistent grain orientation

A technology of butt joint and grain orientation, which is used in measuring devices, welding equipment, material analysis by electromagnetic means, etc., can solve the problems of reducing the service life and failure of electronic products, and achieves low cost, simple process, and guaranteed crystal orientation. The effect of consistency

Inactive Publication Date: 2019-05-24

BEIJING UNIV OF TECH

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, it is a thermodynamic problem to deeply understand and predict the growth mode of Sn dendrites. After the interconnection is completed, each solder joint has a unique crystal orientation, so it is inevitable that there will be some solder joints due to the growth of β-Sn grains. Unfavorable orientation, premature failure during the use of electronic products, thereby reducing the service life of electronic products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0029] Combining the following figure 1 , 2 and 4 specifically illustrate the embodiments of the present invention. Solder solder paste is generally stored in the refrigerator. It needs to be taken out of the refrigerator 4-8 hours in advance and placed at room temperature to restore the viscosity of the solder paste. It needs to be fully stirred before use.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

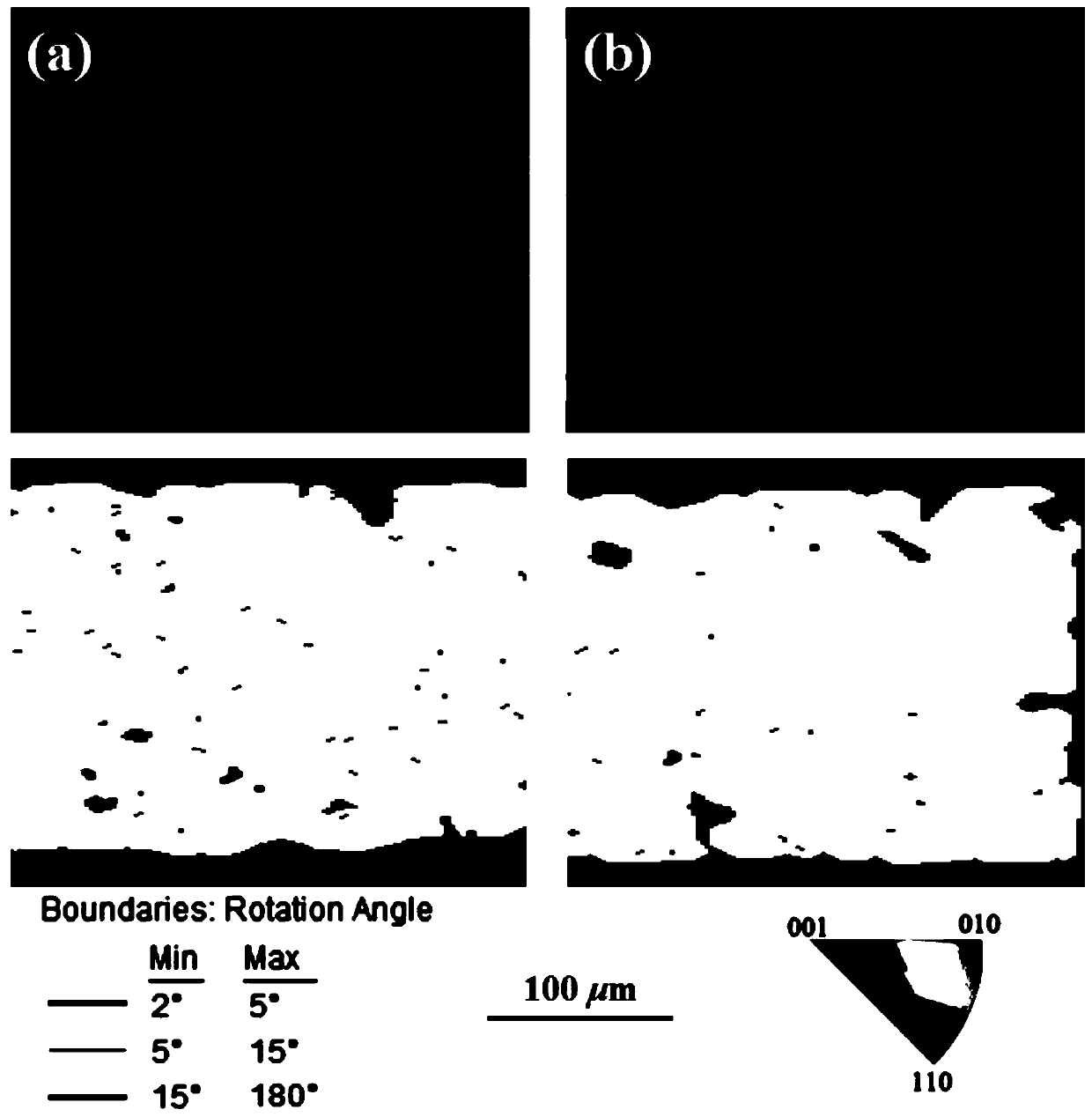

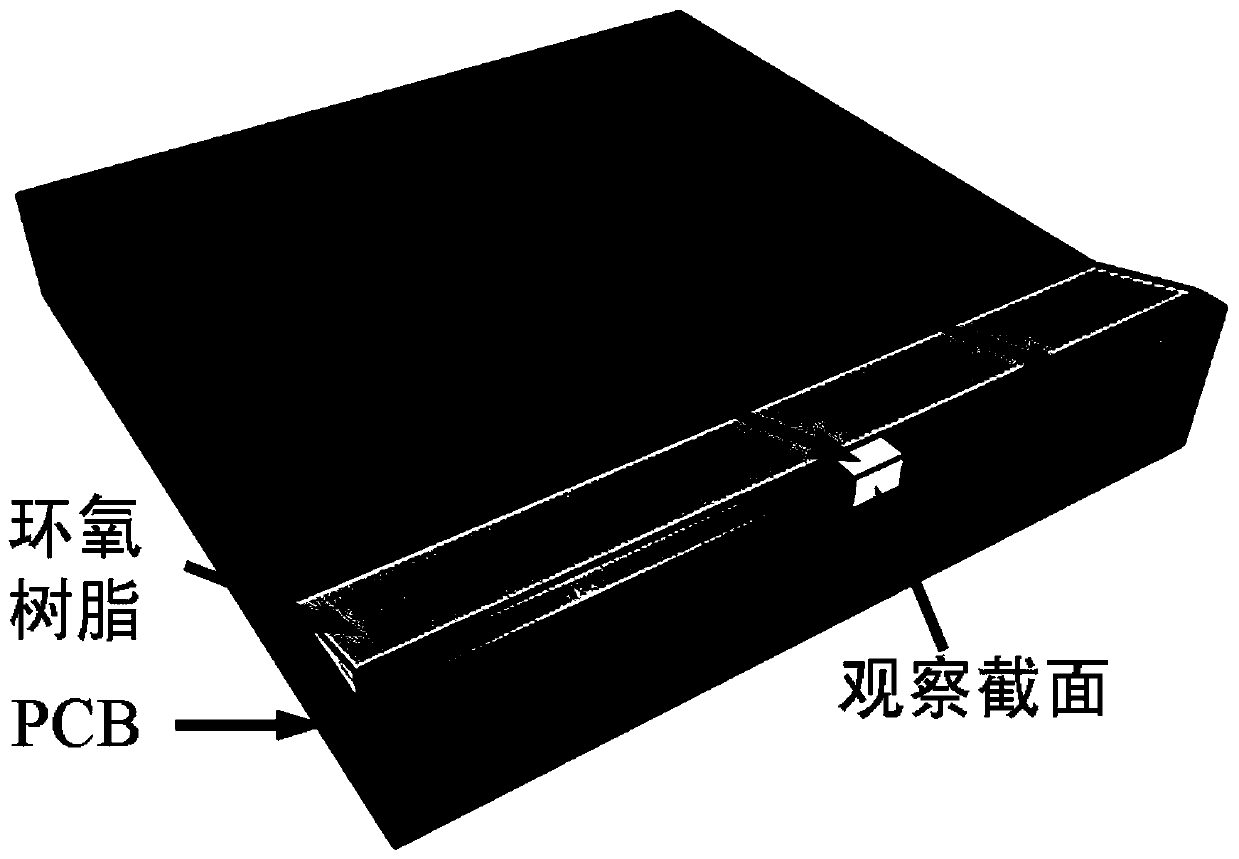

The invention relates to an electromigration test method for a butt joint with consistent grain orientation, and belongs to the field of material preparation and connection. The method comprises the steps that brazing filler metal solder paste is adopted between two bonding pads to be subject to re-fusion welding so as to form a brazing filler metal joint, the brazing filler metal butt joint adheres to a base plate by adopting epoxy resin, at least one side surface of the brazing filler metal joint serves as the cross section of the brazing filler metal butt joint, and the brazing filler metal butt joint which shows single grain orientation under PLM is selected; the monocrystal butt joint is subjected to linear cutting and fine polishing, EBSD data are acquired, the included angle between the crystal grain C axis of the brazing filler metal butt joint and the current direction is determined, the brazing filler metal butt joint adheres to the base plate through the epoxy resin, and relevant test is carried out; and on the premise that the included angle between the crystal grain C axis of a monocrystal welding spot and the current direction is consistent, the reliability evaluation of the welding spot with the comparability is obtained.

Description

technical field [0001] The invention relates to an electromigration test method for a butt joint with consistent grain orientation, which belongs to the field of material preparation and connection, is suitable for preparing micro-brazed butt joints with consistent grain orientation, and is applied to electromigration reliability research. The method can effectively ensure the consistency of the size and grain orientation of the micro-butt joints, thereby ensuring the comparability of the electromigration reliability test data of the brazed butt joints. Background technique [0002] Solder joints are an integral part of microelectronic interconnection, playing the role of mechanical connection and electrical signal transmission. At present, the microelectronic packaging space is reduced, and the heat generation of the chip is intensified. On the one hand, the intermetallic compounds (Intermetallic Compounds, IMCs) generated by the reaction between the solder and the pad meta...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N27/00

CPCB23K31/125

Inventor 汉晶郭福刘建萍

Owner BEIJING UNIV OF TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com