Water-based PVDF coated separator for lithium-ion batteries and preparation method thereof

A lithium-ion battery, water-based technology, applied in secondary batteries, battery components, secondary battery repair/maintenance, etc., to achieve stable performance, extended overall life, and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

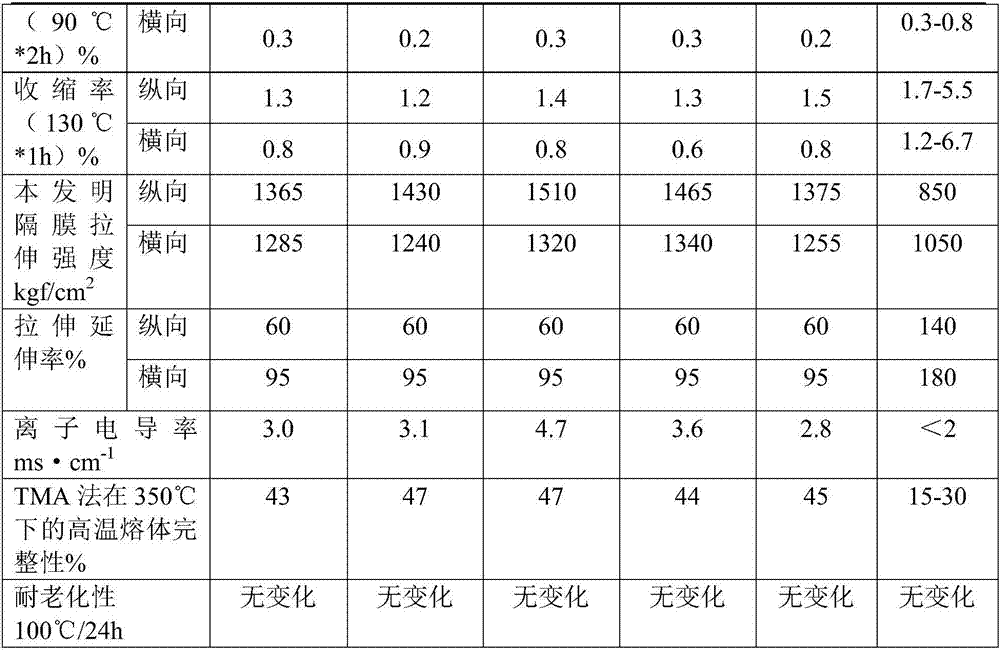

Examples

Embodiment 1

[0029] A water-based PVDF-coated lithium-ion battery diaphragm, comprising a base film with a coating slurry adhered to one or both sides of the film surface, the base film is a PP diaphragm, and the coating slurry is calculated by mass percentage, including water-based PVDF 15% powder, 8% acrylic adhesive, 0.05% fluorocarbon surfactant and cellulose ether dispersant, 0.04% agarin, 0.04% phthalate diester, trimethylolpropane tripropionate 0.04%, CMC solution 0.5%, and the balance is deionized water.

[0030] Described coating slurry is configured by following method:

[0031] A. Add fluorocarbon surfactant and cellulose ether dispersant to water for high-speed dispersion for 10-15 minutes, control the speed at 2000-5000r / min to obtain a mixed solution, then add water-based PVDF powder with the quality of the mixed solution to it, and sand mill Machine high-speed grinding, control the speed of 1000-3000r / min, disperse the water-based PVDF powder evenly to form a PVDF dispe...

Embodiment 2

[0041] A water-based PVDF-coated lithium-ion battery diaphragm, comprising a base film with a coating slurry adhered to one or both sides of the film surface, the base film is a fiber diaphragm, and the coating slurry is calculated by mass percentage, including water-based PVDF Powder 10%, Acrylic Adhesive 9%, Fluorocarbon Surfactant and Cellulose Ether Dispersant 0.07%, Agarin 0.06%, Phthalate Diester 0.05%, Trimethylolpropane Tripropionate 0.07%, CMC solution 0.8%, and the balance is deionized water.

[0042] The above-mentioned coating slurry coating lithium-ion battery separator is prepared by the following method, using a vertical double-sided coating machine or a horizontal high-speed coating machine, and the coating device includes a base film unwinding shaft 1 and a rubber coating roller 2 arranged in sequence , a heating and drying mechanism and a reel 8, the base film unwinding reel 1 is wound with a base film, one end of the base film protrudes from the base film un...

Embodiment 3

[0048] A water-based PVDF coated lithium-ion battery diaphragm, comprising a base film with a coating slurry adhered to one or both sides of the film surface, the base film is a non-woven diaphragm, and the coating slurry is calculated by mass percentage, comprising: Water-based PVDF powder 12%, acrylic adhesive 11%, fluorocarbon surfactant and cellulose ether dispersant 0.08%, agarin 0.05%, phthalate diester 0.06%, trimethylolpropane tripropylene Ester 0.05%, CMC solution 1%, the balance is deionized water.

[0049] The above-mentioned coating slurry coating lithium-ion battery separator is prepared by the following method, using a vertical double-sided coating machine or a horizontal high-speed coating machine, and the coating device includes a base film unwinding shaft 1 and a rubber coating roller 2 arranged in sequence , a heating and drying mechanism and a reel 8, the base film unwinding reel 1 is wound with a base film, one end of the base film protrudes from the base f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unwind tension | aaaaa | aaaaa |

| Unwind tension | aaaaa | aaaaa |

| Unwind tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com