Single-component polyurethane foam caulking agent and preparation method thereof

A technology of polyurethane foam and caulking agent, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc. elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

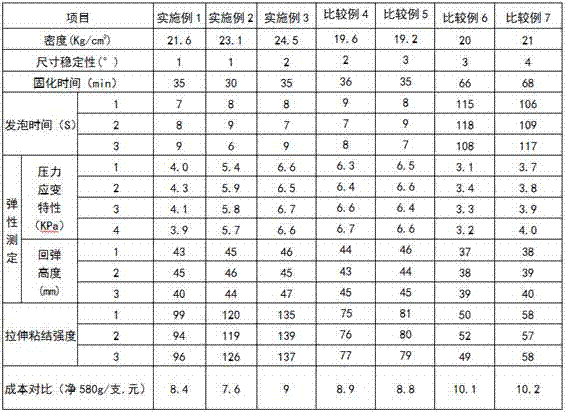

Examples

Embodiment 1

[0034]According to the proportion by weight, add 0.4 parts of diaminodicyclohexylmethane and 0.4 parts of 3,5-dimethylthiotoluenediamine into 0.2 parts of high resilience resin SR-550D, stir for 10 minutes, and the stirring speed is 1000 Resilience agent can be prepared by turning per minute; add 0.15 parts of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane and 0.15 parts of γ-aminopropyltrimethoxysilane to liquid terpene Within 0.2 parts of resin, stir for 15 minutes at a stirring speed of 1200 rpm to obtain a tackifier; add 0.15 parts of triethylenediamine and 0.15 parts of pentamethyldiethylenetriamine into the moisture-cured resin MR- 6080.5 parts, stirred for 5 minutes at a stirring speed of 1500 rpm to obtain the curing agent; then added chlorinated paraffin 52#42 parts into the reaction kettle, and successively added 3 parts of high resilience polyether polyol EP-330N, High resilience polyether polyol EP-3600 2.5 parts, polyether polyol DMN-1000 2.5 parts, silicon dioxid...

Embodiment 2

[0036] According to the proportion by weight, add 0.6 parts of diaminodicyclohexylmethane and 0.6 parts of 3,5-dimethylthiotoluenediamine into 0.8 parts of high resilience resin SR-80NM, stir for 10 minutes, and the stirring speed is 1000 Resilience agent can be prepared by turning per minute; add 0.5 part of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane and 0.5 part of γ-isocyanate propyltrimethoxysilane into liquid terpene Within 1 part of the resin, stir for 15 minutes at a stirring speed of 1200 rpm to prepare a tackifier; add 0.3 parts of triethylenediamine and 0.3 parts of triethylenediamine to 1 part of moisture-curing resin MR-608, Stir for 5 minutes at a stirring speed of 1500 rpm to obtain the curing agent; then add chlorinated paraffin 42#35 parts into the reaction kettle, and successively add 6 parts of high resilience polyether polyol EP-330N, high resilience polyol 4.5 parts of ether polyol EP-3600, 3.5 parts of polyether polyol DMN-1000, 2 parts of silicon diox...

Embodiment 3

[0038] According to the proportion by weight, add 0.9 parts of diaminodicyclohexylmethane and 0.9 parts of 3,5-dimethylthiotoluenediamine to 0.6 parts of high resilience resin SR-550D, 0.6 parts of high resilience resin SR-80NM In one portion, stir for 10 minutes at a stirring speed of 1000 r / min to prepare a resilient agent; add 1 part of γ-aminopropyltrimethoxysilane and 1 part of γ-isocyanate propyltrimethoxysilane to liquid terpene Within 2 parts of the resin, stir for 15 minutes at a stirring speed of 1200 rpm to obtain a tackifier; add 0.5 parts of triethylenediamine and 0.5 parts of pentamethyldiethylenetriamine into the moisture curing resin MR-6082 part, stirred for 5 minutes at a stirring speed of 1500 rpm to obtain the curing agent; then chlorinated paraffin 52#39 parts were added to the reaction kettle, and 9 parts of high resilience polyether polyol EP-330N, high 6.5 parts of rebound polyether polyol EP-3600, 4.5 parts of polyether polyol DMN-1000, 3 parts of sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com