Preparation method of beta-phenylethyl alcohol

A technology for phenethyl alcohol and benzyl alcohol, which is applied in the field of preparing beta-phenethyl alcohol, can solve the problems of difficult recovery of catalyst, complex catalyst system, low catalyst selectivity, etc., and achieves low production cost, high activity and selectivity, and high selectivity high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

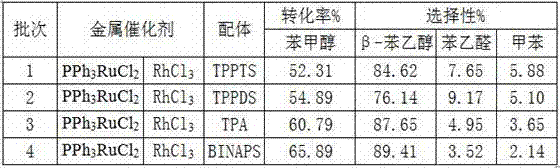

Examples

Embodiment 1

[0036] Embodiment 1 A kind of preparation method of β-phenylethyl alcohol

[0037] Include the following steps:

[0038] (1) Add catalyst, water, benzyl alcohol

[0039] Add 1g of ruthenium chloride, 6.8g of sodium triphenylphosphinetriisosulfonate TPPTS, and 300g of water into a 1000ml autoclave with magnetic stirring and a temperature controller; then add 200g of benzyl alcohol, replace it with nitrogen three times, and then use Replaced by hydrogen three times.

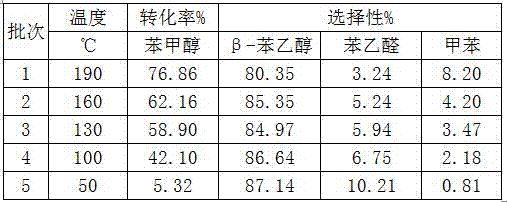

[0040] (2) Pass CO, H 2 mixed gas

[0041] Heating to 150°C, CO / H 2 The molar ratio of the mixed gas of 1:2 is pressurized to 6.0MPa, and the mixed gas,

[0042] Keep feeding to maintain the system pressure at 6.0MPa.

[0043] (3) Reaction

[0044] Stir at a speed of 700rpm, and take samples during the reaction to analyze the progress of the reaction. When the conversion rate of benzyl alcohol is greater than 60%, cool it with water, press out the reaction liquid, let it stand for stratification, and the wat...

Embodiment 2

[0046] Embodiment 2 A kind of preparation method of β-phenylethyl alcohol

[0047] Include the following steps:

[0048] (1) Add catalyst, water, benzyl alcohol

[0049] 1g rhodium chloride and 2.0g1,3,5-triaza-7-phosphoradamantane TPA, 300g water are joined in the 1000ml autoclave that has magnetic stirring and thermostat; Then add 200g benzyl alcohol, use Nitrogen was replaced three times, followed by hydrogen replacement three times.

[0050] (2) Pass CO, H 2 mixed gas

[0051] Heating to 150°C, CO / H 2 The mixed gas with a molar ratio of 1:1 is pressurized to 4.0MPa, and the mixed gas is continuously fed to maintain the system pressure at 4.0MPa.

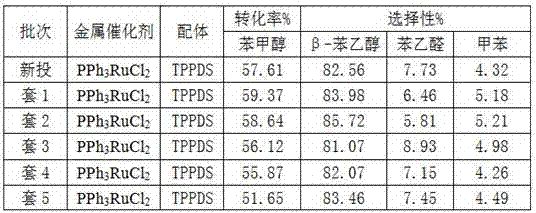

[0052] (3) Reaction

[0053] Stir at 700rpm, take samples during the reaction and analyze that the conversion rate of benzyl alcohol is greater than 60%, cool it with water, press out the reaction solution, let it stand for stratification, the water phase containing the catalyst can continue to be applied to the next batch ...

Embodiment 3

[0055] Embodiment 3 A kind of preparation method of β-phenylethyl alcohol

[0056] Include the following steps:

[0057] (1) Add catalyst, water, benzyl alcohol

[0058] Add 1g of carbonyl rhodium acetylacetonate and 8.0g of 1.1'-binaphthyl-2.2'-sodium diphenylphosphine bisulfonate BINAPS, 300g of water into a 1000ml autoclave with magnetic stirring and a thermostat; then add 200g of benzene Methanol was replaced three times with nitrogen, and then three times with hydrogen.

[0059] (2) Pass CO, H 2 mixed gas

[0060] Heating to 100°C, CO / H 2 The mixed gas with a molar ratio of 1:2 is pressurized to 6.0MPa, and the mixed gas is continuously fed to maintain the pressure of the system at 6.0MPa.

[0061] (3) Reaction

[0062] Stir at 700rpm, sample and analyze the conversion rate of benzyl alcohol during the reaction process is greater than 60%, cool with water, press out the reaction solution, let it stand for stratification, the water phase containing the catalyst can con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com