Tempered glass for side window of automobile

A tempered glass and automobile technology, applied in the field of automobile glass, can solve the problems of increasing fuel consumption and increasing the overall quality of the car, and achieve the effect of reducing fuel consumption, good physical and chemical properties, and reducing the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

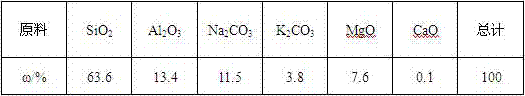

[0013] Example 1: In one example, using SiO 2 、Al 2 o 3 、Na 2 CO 3 、K 2 CO 3 , MgO, and CaO are used as raw materials, melted at 1650°C, and after being shaped by the float process, a high-alumina-silicate glass sample 1 with a certain composition is obtained, with a thickness of 1.8mm; the amount of the chemical raw materials is expressed in mass percent Count ω / % see the table below.

[0014]

Embodiment 2

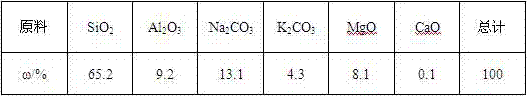

[0015] Example 2: In one example, using SiO 2 、Al 2 o 3 、Na 2 CO 3 、K 2 CO 3 , MgO, and CaO as raw materials, melted at 1650°C, and formed by the float process, a high-alumina-silicate glass sample 2 with a certain composition was obtained, with a thickness of 2.1mm. The amount of chemical raw materials used is shown in the following table in terms of mass percentage ω / %.

[0016]

Embodiment 3

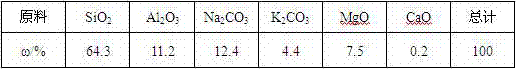

[0017] Example 3: In one example, using SiO 2 、Al 2 o 3 、Na 2 CO 3 、K 2 CO 3 , MgO, and CaO as raw materials, melted at 1650°C, and formed by the float process, a high-alumina-silicate glass sample 3 with a certain composition was obtained, with a thickness of 2.0mm. The amount of chemical raw materials used is shown in the following table in terms of mass percentage ω / %.

[0018]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com