High-Speed Manufacturing of Micro-Features in Printed Products

A technology for printing products and micro-features, which is applied in the manufacturing field of printing products, can solve the problems of ink dispersion, deterioration of wiping efficiency, abrasion, etc., and achieve the effect of high printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Throughout the drawings, the same reference numerals are used for similar or corresponding elements.

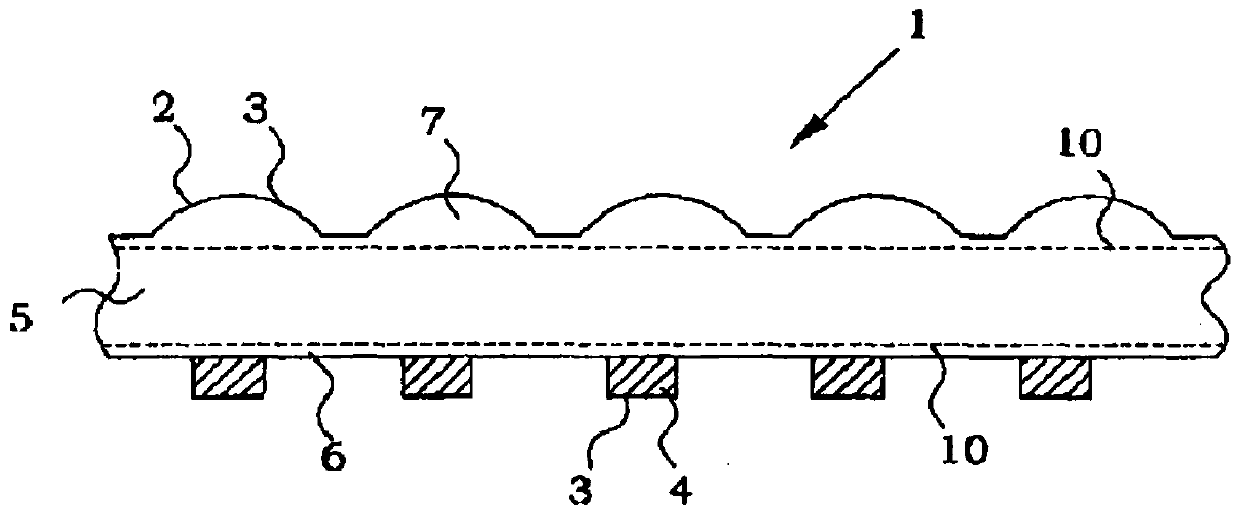

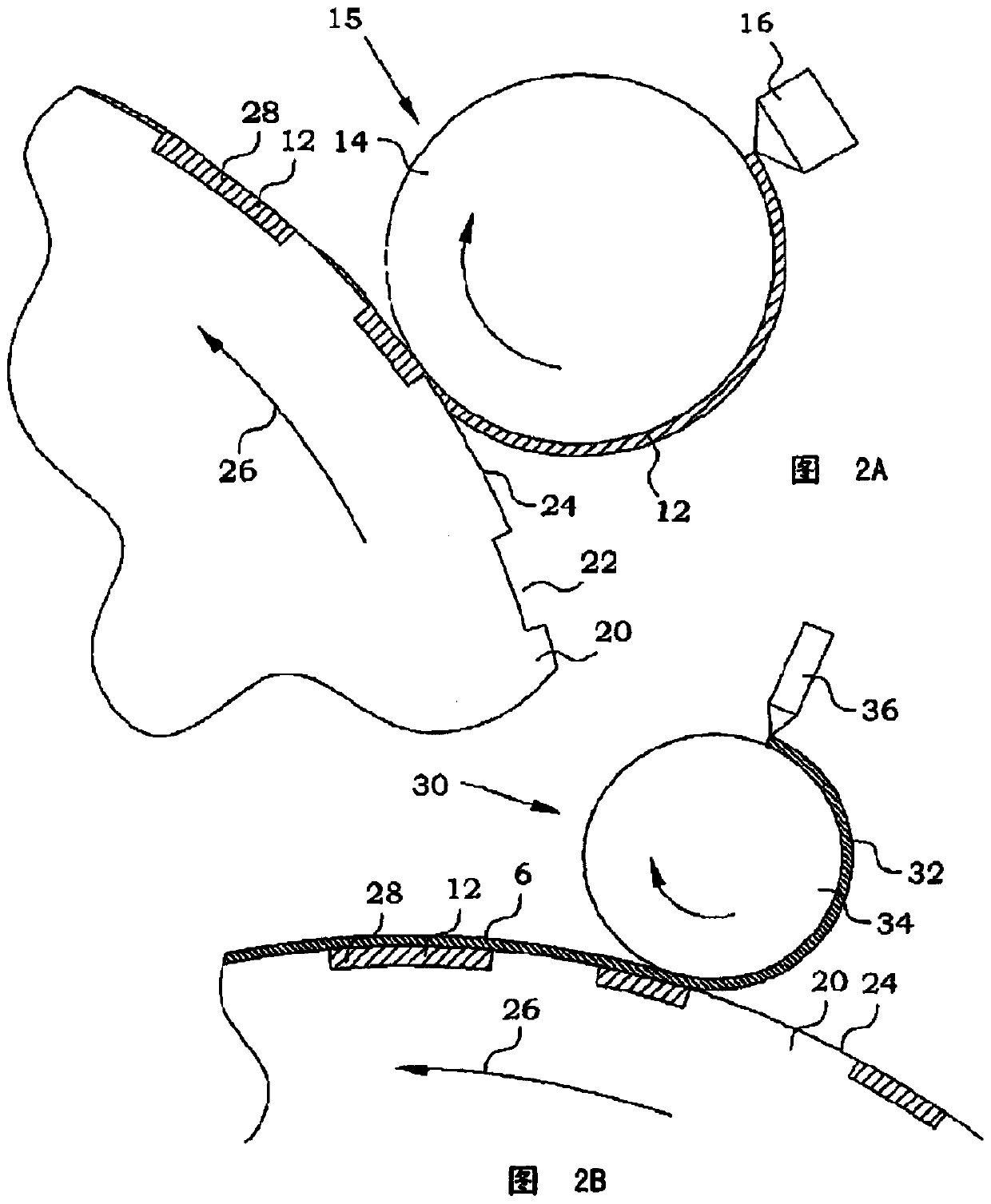

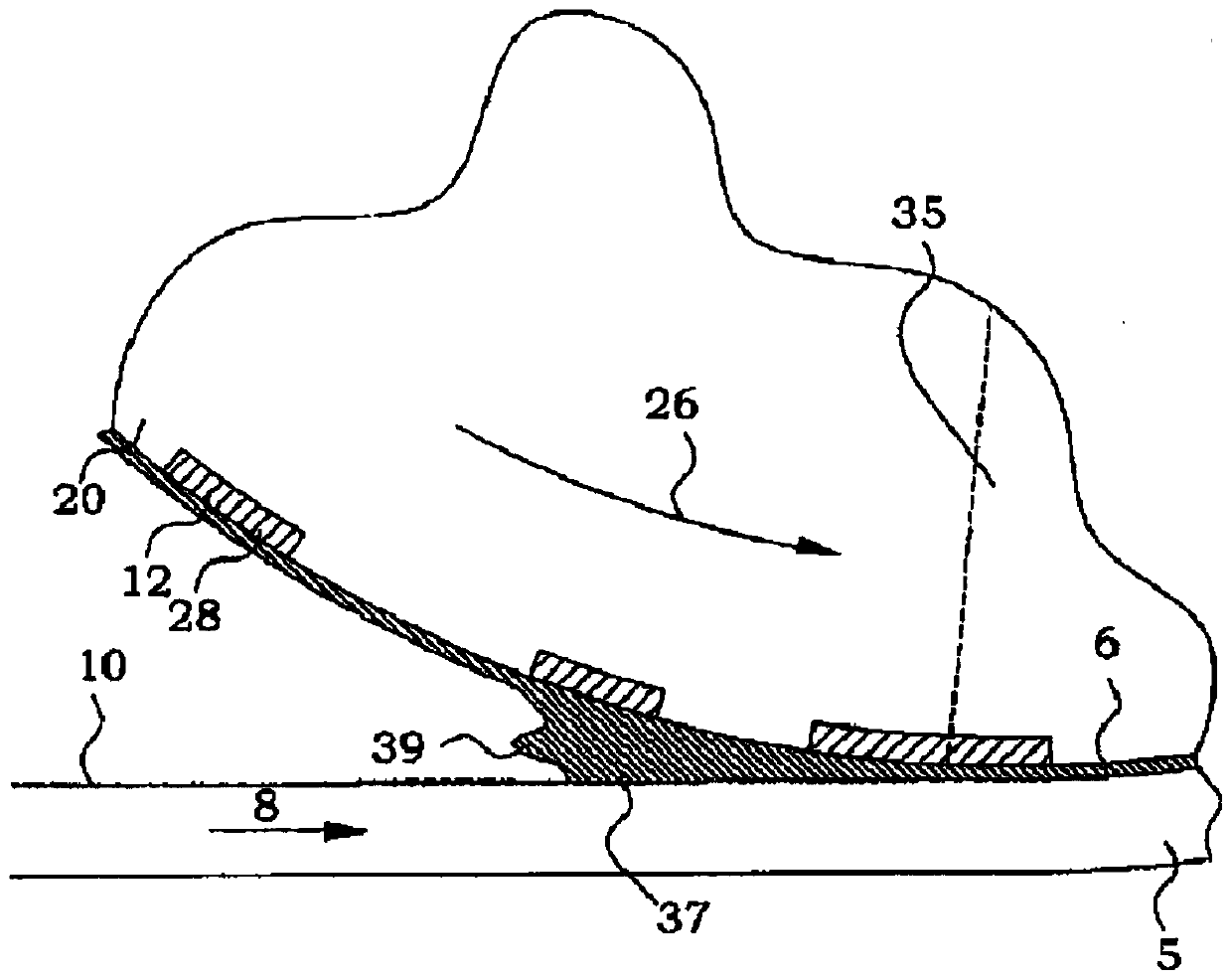

[0022] A product manufactured according to the present teaching comprises a body constituting, either in the product, or in an intermediate product, a substrate sheet having a finite thickness with respect to its extension in an orthogonal direction thereof. The product has printed product microfeatures disposed on or in one or both major surfaces of the base sheet. As an example, one embodiment of the product may include primary product microfeatures on a first side of a base sheet and secondary product microfeatures on an opposite side of the base sheet. Primary product microfeatures are usually positionally related to secondary product microfeatures. Other embodiments of the product may include three or more sets of product microfeatures. In its most basic form, the product comprises a substrate sheet with product microfeatures printed on only one of its surfaces....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com