An automatic forging device for square tubes

An automatic and driving rod technology, which is applied in the direction of the hammer driving device, forging/pressing/hammer device, power hammer, etc., can solve the problems of complete forging of the outer prism surface of the square tube and poor forging effect, and achieve the forging effect Good, highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

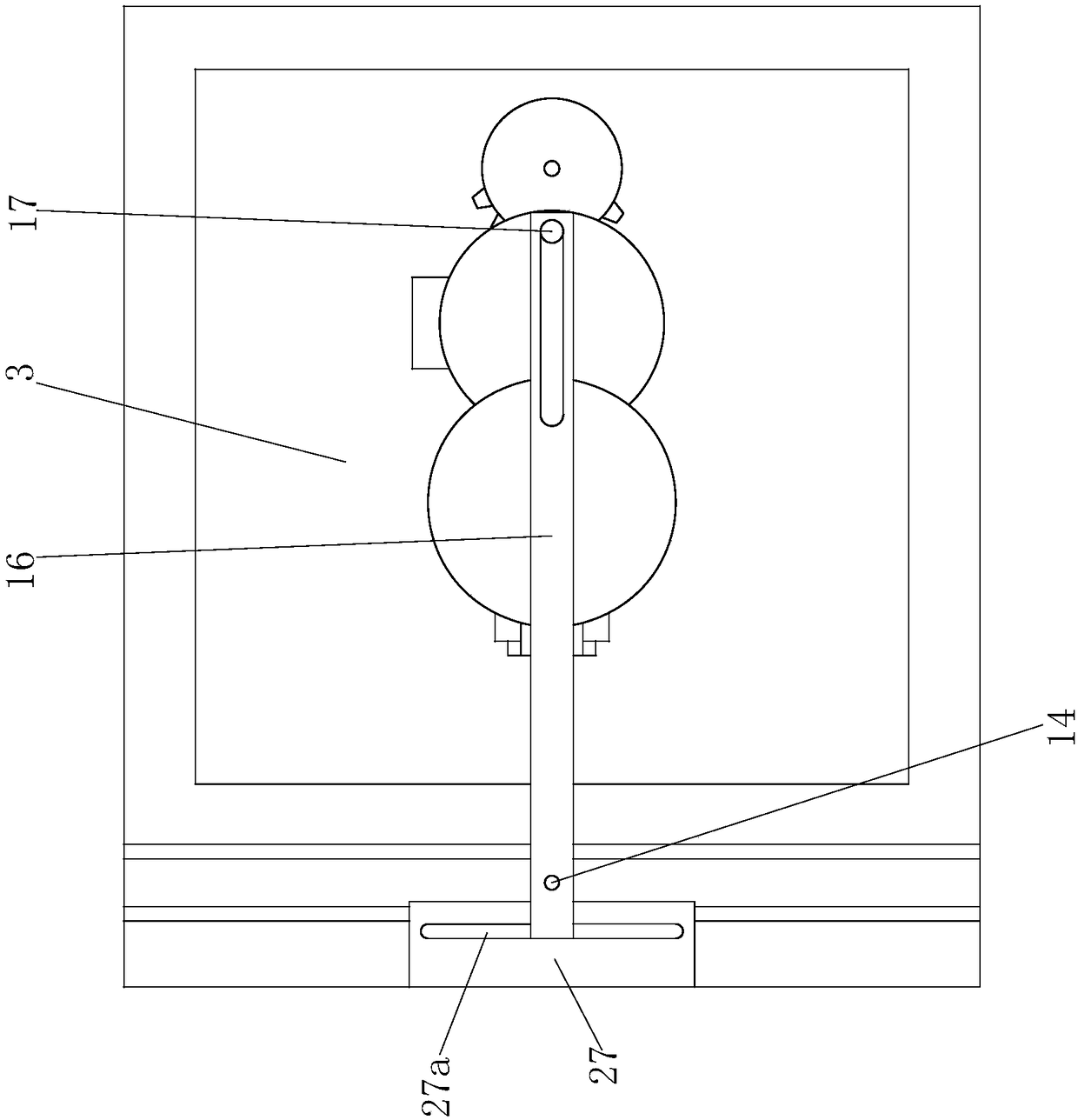

[0022] Such as Figure 1 to Figure 7 As shown, an automatic forging device for a square tube includes a base plate 1, and the base plate 1 is respectively fixed with a fixed frame 3, a placement table 2, and an L-shaped limiting frame 27 from right to left. A motor 4 is installed, and the motor 4 is connected with a central shaft 5 cooperating with the fixed frame 3 through a bearing.

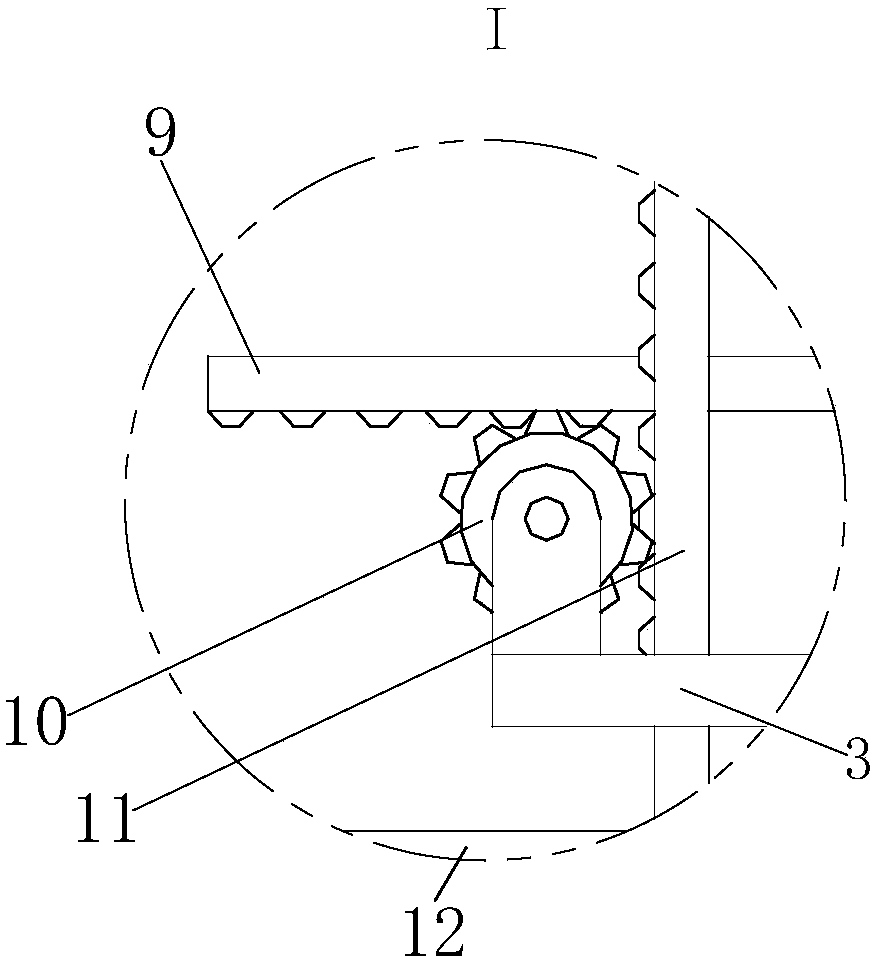

[0023] A guide rail frame 6 cooperating with the central shaft 5 through bearings is installed above the fixed frame 3 , and a horizontal plate frame 7 is installed on the horizontal slide of the guide rail frame 6 , and the middle part of the horizontal plate frame 7 is provided with a horizontal sliding plate with the central shaft 5 . The matching transverse groove 7a, the left side of the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com