Tobacco curing room

The technology of flue-cured tobacco room and heating room is applied in the field of flue-cured tobacco room, which can solve the problems of slow curing, uneven heat, different appearance of tobacco leaves, and achieve the effects of consistent temperature and wind speed, avoiding the quality of flue-cured tobacco and making it convenient to make.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

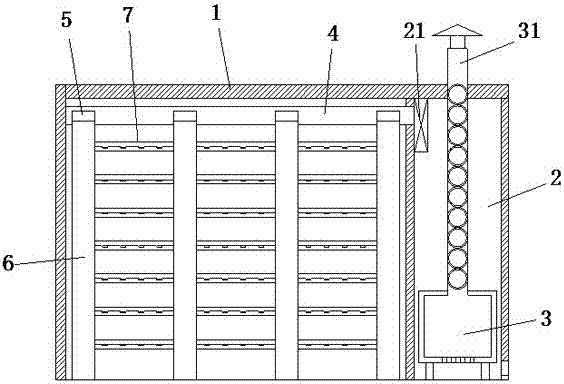

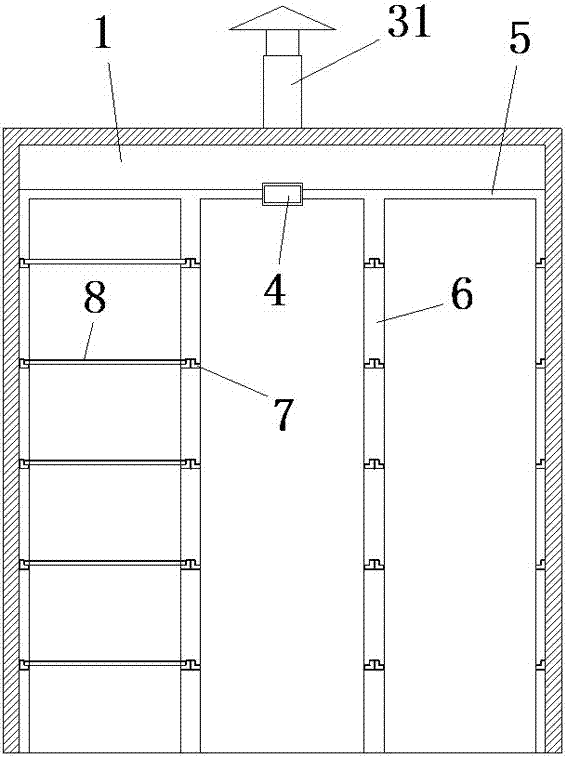

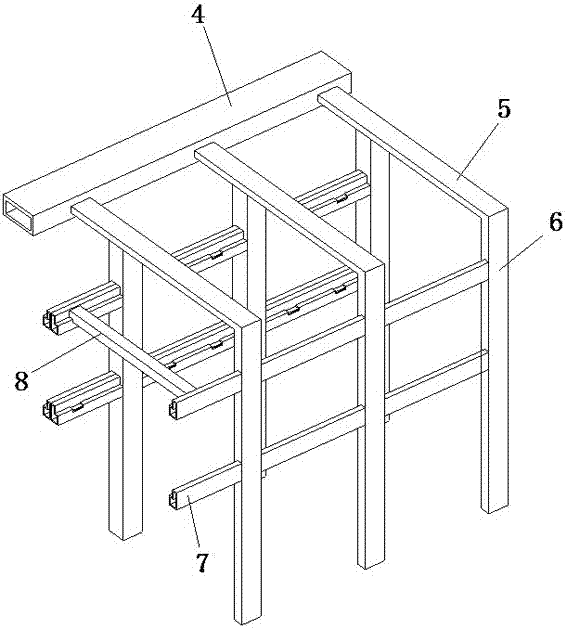

[0019] Embodiment one: if Figure 1~7 As shown, a flue-cured room includes a flue-cured room body 1 and a heating room 2 arranged at the rear end of the flue-cured room. An insulated door is arranged on the front wall of the flue-cured room. A coal-burning hearth 3 is arranged at the bottom of the heated room. The top is provided with a fan 21 for blowing heating to the flue-cured room. A main pipe 4 equal in length to the inside of the flue-cured room is provided in the middle of the top of the flue-cured room. One end of the main pipe is connected to the outlet of the fan, and the other end is closed. There are several branch pipes 5 evenly distributed on both sides of the main pipe, one end of the branch pipe is connected with the main pipe, and the other end is closed, and a plurality of vertical pipes 6 are uniformly distributed at the bottom of the branch pipe, and the bottom ends of the vertical pipes are fixed on the ground , the top is connected with the branch pipe; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com