Double-cavity excitation enhanced microwave plasma torch generation device

A microwave plasma and microwave plasma technology, applied in the field of plasma, can solve the problems of quenching discharge form, constraint, microwave plasma afterglow space extension distance and limited volume, etc., and achieve the effect of increasing the maximum power and good energy coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

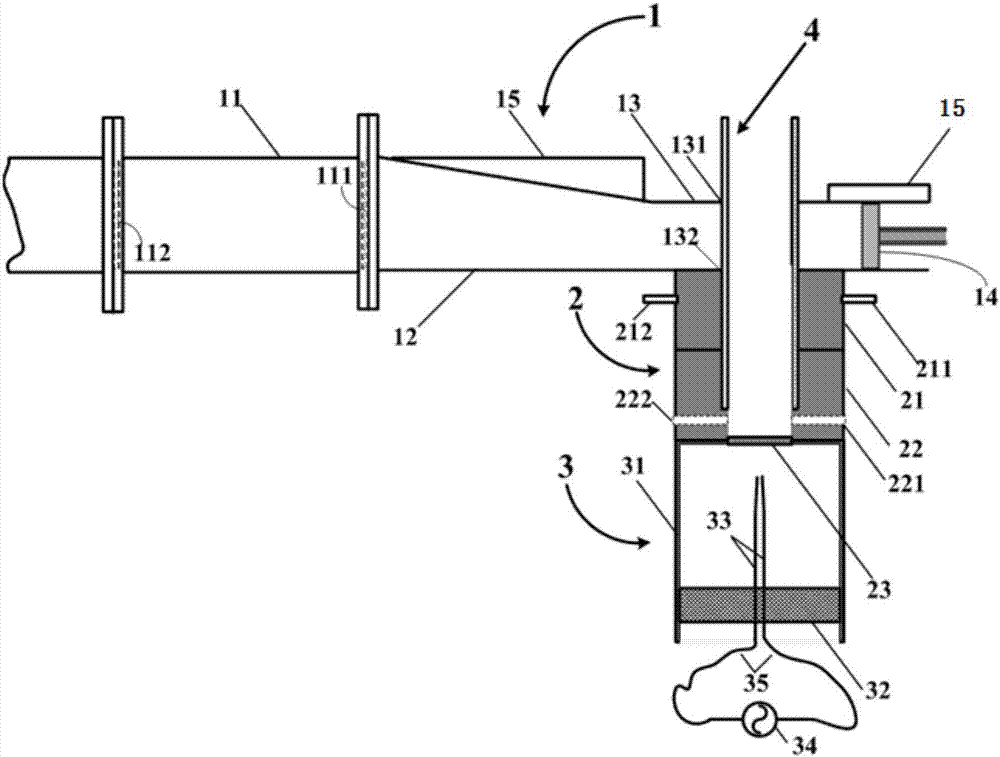

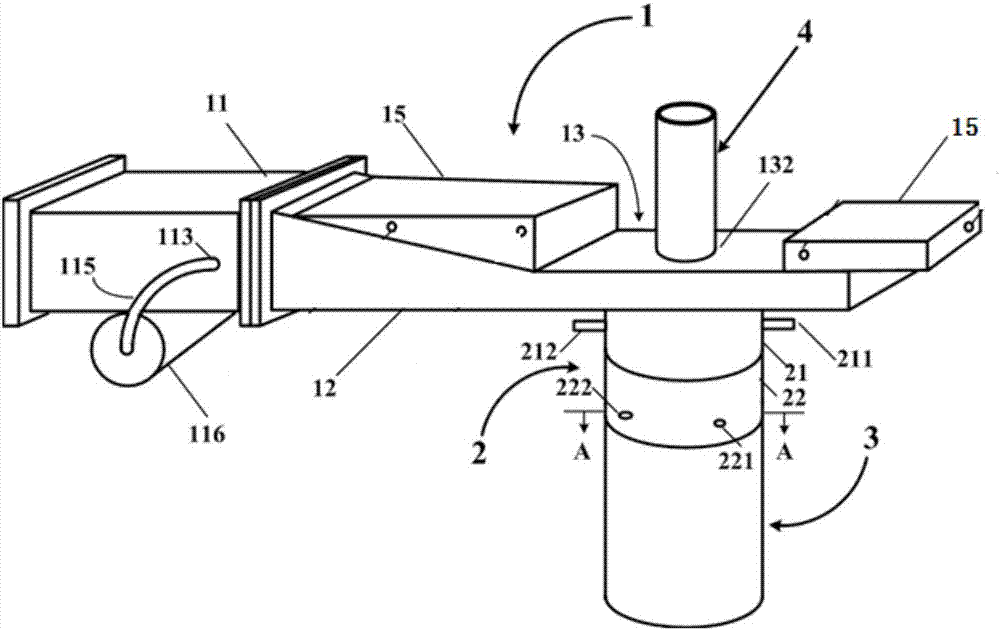

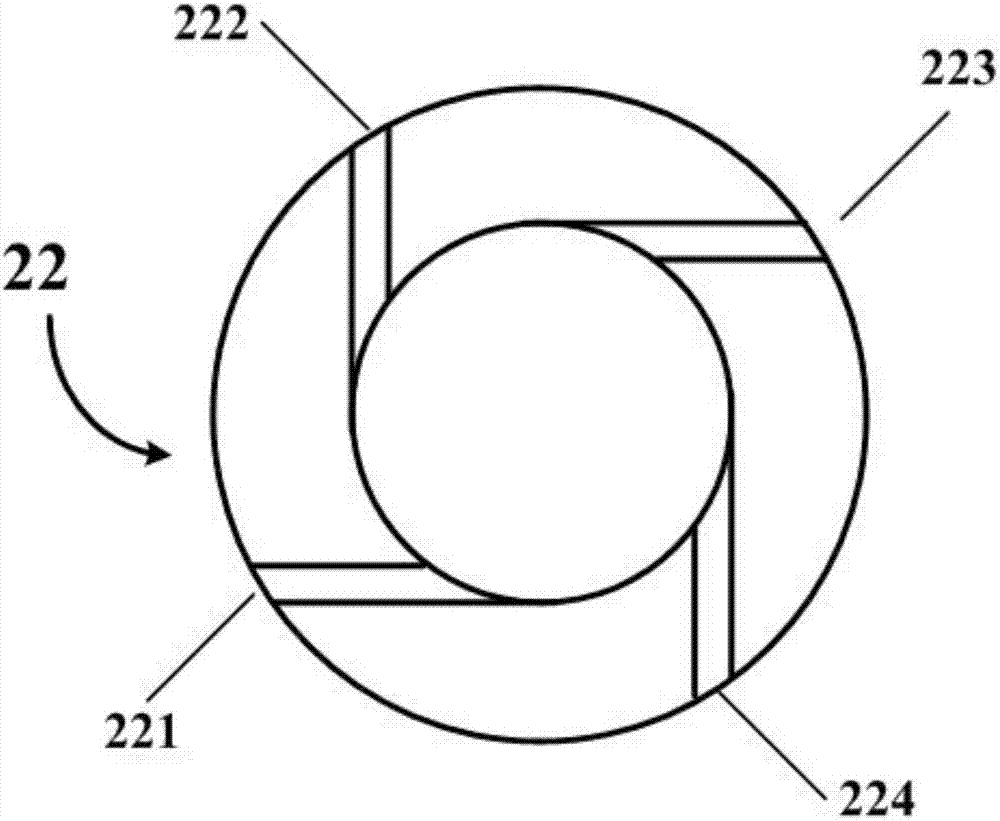

[0030] An enhanced microwave plasma torch generating device with dual-cavity excitation, including a microwave magnetron, a circulator, a directional coupler, a microwave plasma coupling waveguide 1, a cylindrical waveguide 2, an igniter 3 and a discharge tube 4, and a microwave magnetron After the control tube, the circulator, and the directional coupler are connected in series in sequence, the directional coupler is connected to the microwave plasma coupling waveguide 1, which is characterized in that:

[0031] The microwave plasma coupling waveguide 1 comprises a thermal resistance waveguide 11, an impedance converter 12 with tapered waveguide cross-section, a compressed rectangular waveguide 13, a metal short circuit piston 14, water cooling jackets 15 and 16; the metal short circuit piston 14 is located at the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com