Permanent magnet synchronous motor (PMSM) closed-loop control system

A permanent magnet synchronous motor, closed-loop control technology, applied in control systems, AC motor control, single motor speed/torque control, etc. Development needs and other issues, to achieve the effect of high application and promotion value, high reliability, and perfect functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] 1 Working principle of permanent magnet synchronous motor

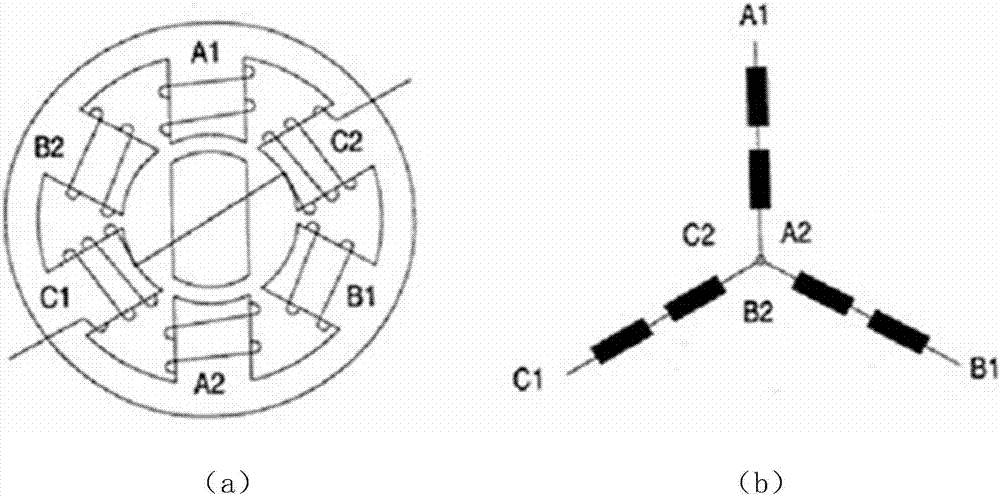

[0031] The internal structure of the permanent magnet synchronous motor is shown in figure 1 :

[0032] From figure 1 It can be seen that the permanent magnet synchronous motor is composed of two parts: the rotor and the stator. The stator refers to the part of the motor that does not move when it rotates. The space for placing it is three-phase symmetrical armature windings A1A2, B1B2, and C1C2 with a mutual difference of 120 degrees. They are connected in a star or triangle shape. The rotor is the part that rotates when the motor rotates. A pair of poles made of permanent magnet steel. In addition, compared with ordinary synchronous motors, permanent magnet synchronous motors must also be equipped with a rotor position detector to detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com