Preparation method of enameled wire

A technology of enameled wire and wire body, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, electrical components, etc. It can solve the problems of scratches and scratches, affect the surface quality of enameled wire, etc., and achieve the effect of avoiding friction and ensuring surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

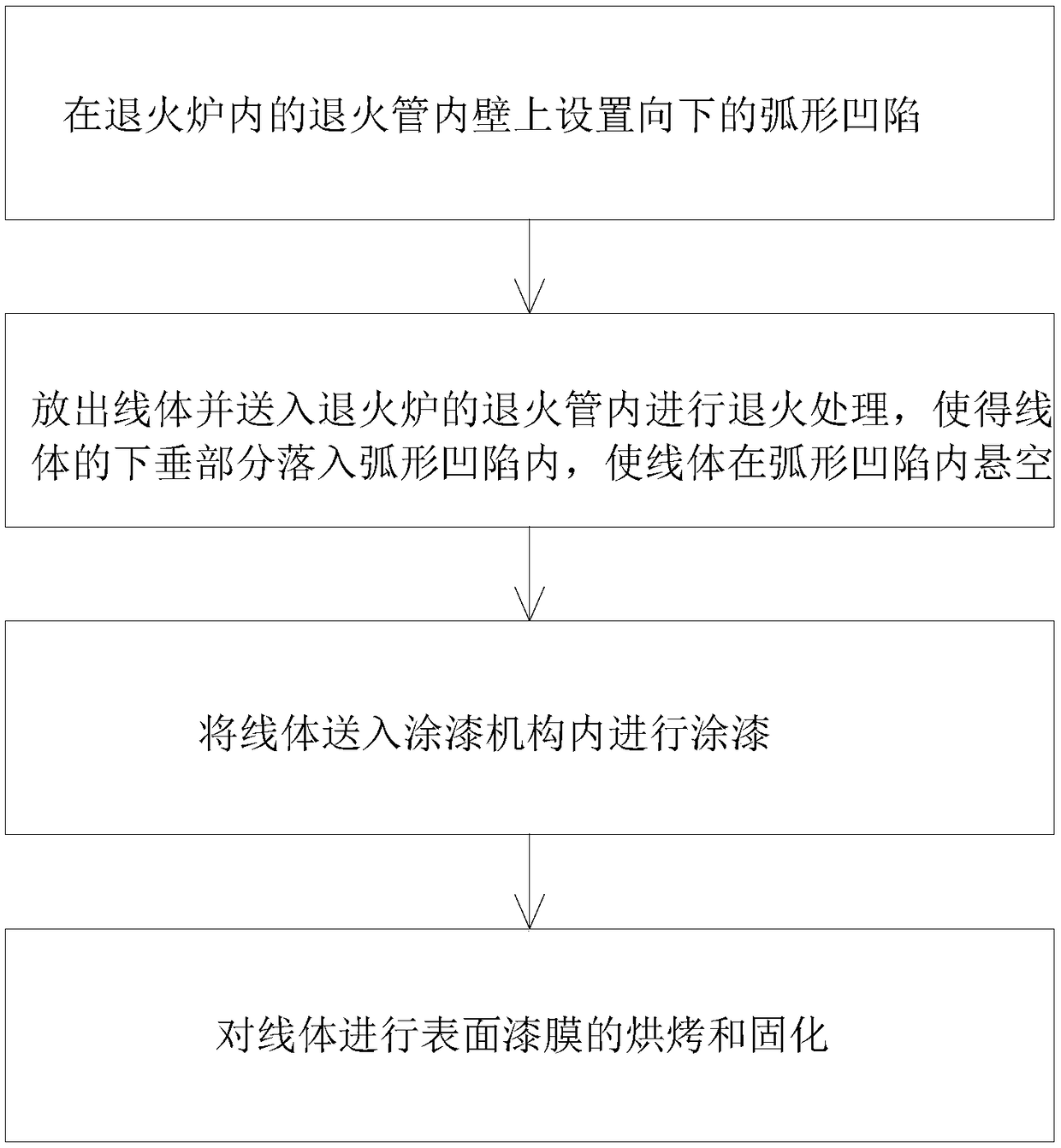

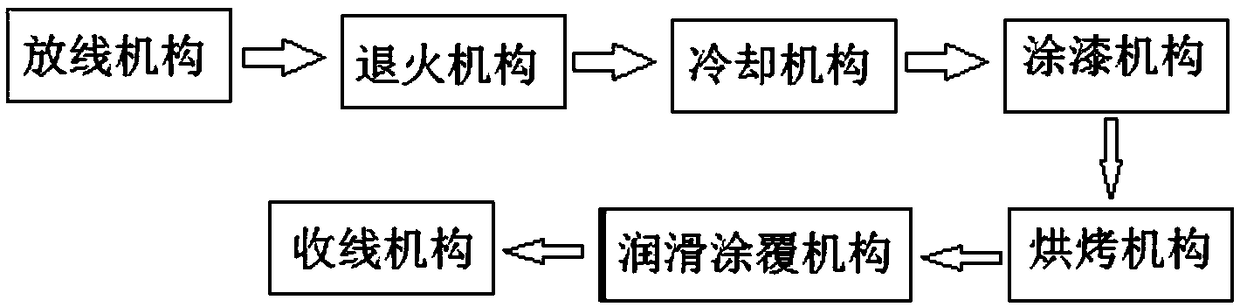

[0040] The enameled wire production system that the preparation method of enameled wire of the present invention is applied, such as figure 2 As shown, according to the traveling direction of the wire body 1, it includes a pay-off mechanism, an annealing mechanism, a cooling mechanism, a painting mechanism, a baking mechanism, a lubricating coating mechanism and a take-up mechanism, wherein the pay-off mechanism includes a pay-off reel ,Such as image 3 and Figure 4 As shown, the pay-off cover 101 on the top of the pay-off reel is provided with a protective cover 102, and the circumferential side wall of the protective cover 102 is a smooth arc-shaped side wall, and the arc-shaped side wall is tangent to the bottom surface of the pay-off cover 101, This smooth arc-shaped side wall transition design can effectively avoid the wear between the wire body 1 and the pay-off cover 101, prevent the surface damage of the wire body 1 when the wire is unwound, and ensure the surface q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com