Novel mechanical material level switch

A material level switch, mechanical technology, applied in the field of new mechanical material level switches, can solve problems such as inability to see the working status of the instrument intuitively, false alarm of the transmission shaft, failure of material level monitoring, etc., and achieves wide application range and easy operation Reliable effect on maintenance and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

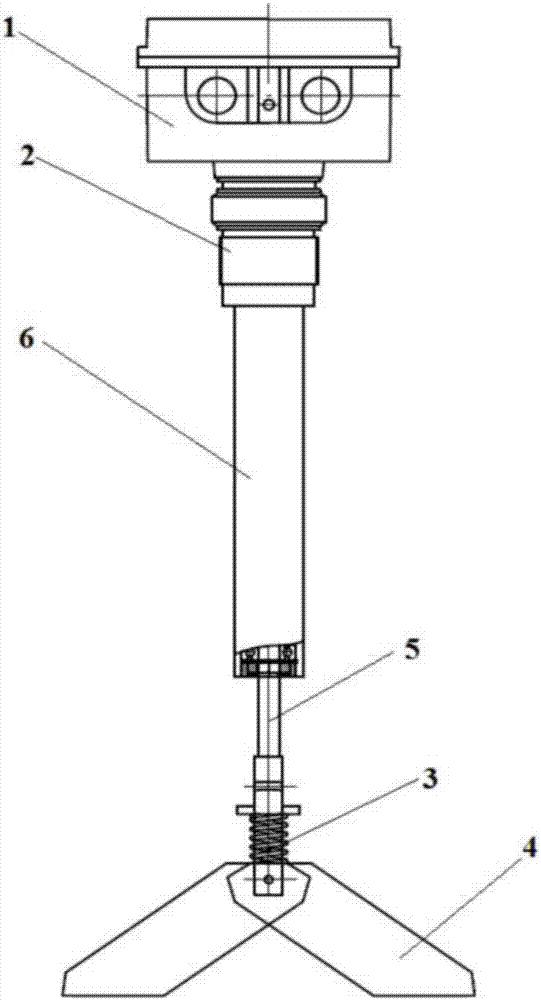

[0019] Such as Figure 1-2 As shown, a new mechanical level switch of this embodiment includes a housing 1, a micro motor, a micro switch, a transmission shaft 5 and a detection paddle 4, and the housing 1 is provided with a micro motor and a micro switch The switch, the micro motor is connected to one end of the transmission shaft 5 through the connecting sleeve 2 on the outside of the housing 1, and the other end of the transmission shaft 5 is connected to a piece of detection paddle 4 with a swing angle of 25°-35° through the return spring 3; the housing 1 is also provided with a high-brightness two-color status indicator light, which is connected to the status indication terminal in the housing 1.

[0020] Working principle: The micro motor drives the detection paddle 4 in the hopper to rotate through the transmission shaft 5. When the material reaches the position of the measurement and detection paddle 4, it will prevent the detection paddle 4 from rotating, and the micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com