Compact explosion-proof protector

A protector, compact technology, applied in the direction of emergency protection devices, electrical components, circuits, etc., can solve the problems of the limitation of explosion-proof performance, the difficulty of realizing arc extinguishing materials, and the inability to reduce the volume, so as to achieve space saving, good flexibility and High adsorption and strong long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The composition of the arc extinguishing material is as follows by weight: 10 parts of polyamide resin or polyimide resin or silicone resin, 6 parts of anhydrous magnesium oxide, 5 parts of gas phase silicon dioxide, and 0.2 part of sodium chloride.

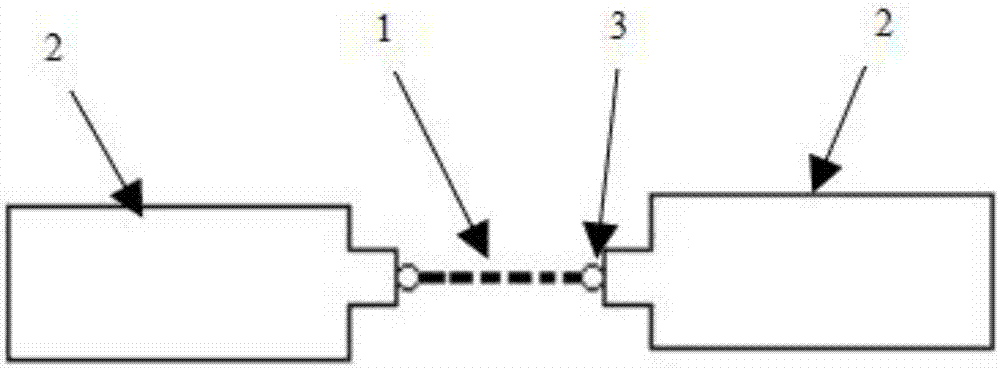

[0029] Such as figure 1 As shown, a whole melt with arc-extinguishing material attached is cut into a small section, and the tinned copper sheet is processed into a "convex" shape as electrode 2. The width of the joint between electrode 2 and melt 1 is narrow, and electrode 2 and The melt 1 is welded together by solder beads 3 to form an electrical connection, the electrode 2 coincides with the center line of the melt 1, and both are placed horizontally.

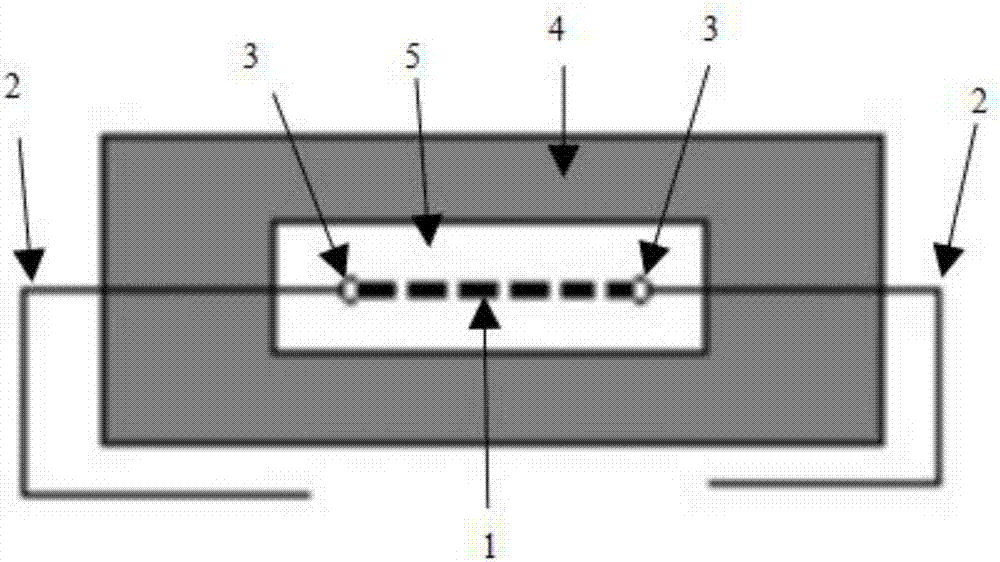

[0030] Such as figure 2 As shown, an encapsulation layer 4 is formed outside the melt 1 by plastic sealing, a cavity is formed in the encapsulation layer 4, the melt 1 is suspended in the cavity, and there is a certain gap between the arc extinguishing material 7 and t...

Embodiment 2

[0033] The composition of the arc extinguishing material is as follows by weight: 10 parts of polyamide resin or polyimide resin or silicone resin, 6 parts of anhydrous magnesium oxide, 5 parts of gas phase silicon dioxide, and 0.2 part of sodium chloride.

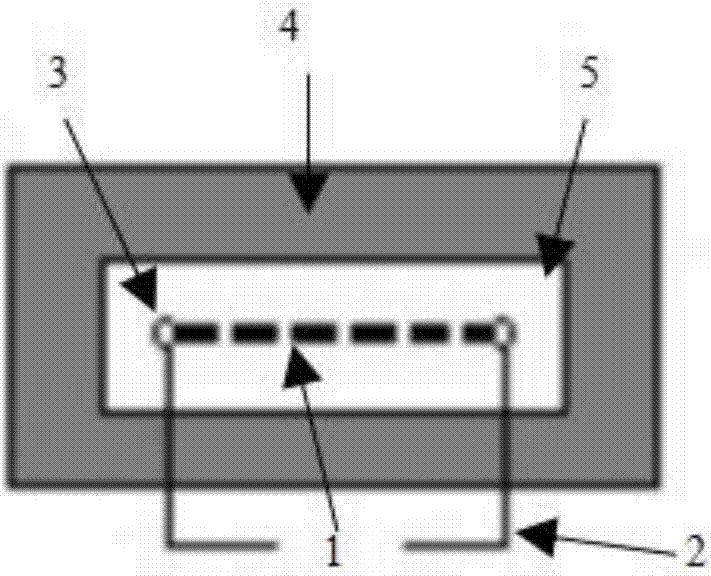

[0034] Such as image 3 As shown, the electrode 2 is processed into a "convex" shape, and is welded together with the melt 1 by solder beads 3 to form an electrical connection. Dip into the mixed arc extinguishing material, then bake and solidify. The electrode 2 is perpendicular to the center line of the melt 1, and the melt 1 is placed horizontally. A part of the electrode 2 protrudes out of the encapsulation layer and is bent into a relative right angle after processing. The bottom part is horizontal and close to the encapsulation layer. There is no contact between the two "L" shaped right angles.

[0035] The advantage of this embodiment is that the electrode 2 is perpendicular to the melt 1, and after the melt is as...

Embodiment 3

[0037] The composition of the arc extinguishing material is as follows by weight: 10 parts of polyamide resin or polyimide resin or silicone resin, 6 parts of anhydrous magnesium oxide, 5 parts of gas phase silicon dioxide, and 0.2 part of sodium chloride.

[0038] Such as Figure 4As shown, the electrode 2 and the melt 1 are welded together by solder beads 3 to form an electrical connection, and then part of the melt is dipped into the arc extinguishing material, and baked and solidified. The electrode 2 is perpendicular to the center line of the melt 1, and the melt 1 placed horizontally. The encapsulation layer 4 wraps the melt 1, the arc extinguishing material 7, the fixed terminals 3 on both sides, and a part of the electrodes 2 on both sides. The substrate 6 is arranged under the encapsulation layer 4, and the electrodes 2 extend into the substrate 6 through the encapsulation layer 4. , and bend to both sides to protrude from the substrate, and the part protruding from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com