High-pressure gas diffuser

A high-pressure gas and diffuser technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of low detection accuracy and the inability to accurately detect whether the compressed air meets the requirements of the clean room, and achieve simple structural design and control methods Simple and intuitive, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

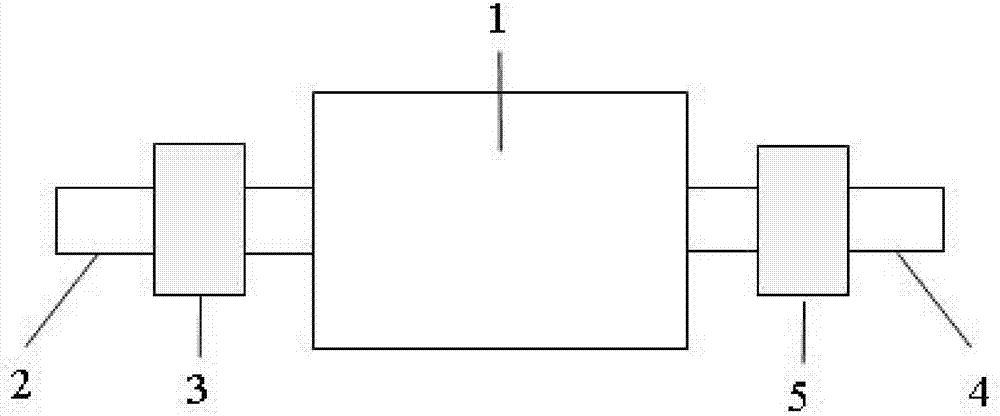

[0015] attached figure 1 It is a high-pressure gas diffuser according to the present invention, comprising a sealed cavity 1; one side of the sealed cavity 1 is provided with an air inlet pipe 2, and the other side is provided with an outlet pipe 4; the air inlet pipe 2, the sealed cavity 1. The air outlet pipes 4 are connected sequentially; the air inlet pipe 2 is connected with a high-pressure gas supply device (omitted in the figure), and the air outlet pipe 4 is connected with a dust particle counter or a plankton sampler device (omitted in the figure); The air pipe 2 is provided with a pressure regulating valve 3, which can be used to adjust the pressure of the high-pressure gas supply device when supplying air to the sealed cavity 1; the air outlet pipe 4 is provided with a flow meter 5, and the flow rate The meter 5 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com