A kind of hard multi-layer composite pvc floor

A multi-layer composite and flooring technology, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of non-compliance with environmental protection requirements, poor ductility and toughness, easy warping, deformation, etc., and achieve stable and reliable physical indicators. Increase ductility and toughness, improve the effect of low temperature embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The hard multi-layer composite PVC floor is made by the following methods:

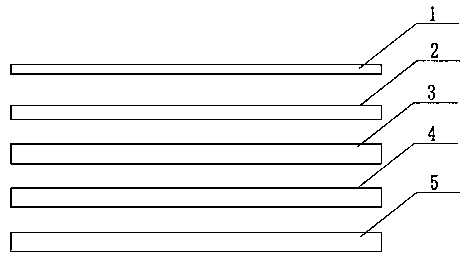

[0038] 1) Pressing: Put the wear-resistant layer 1, the color film layer 2, the middle material layer 3, the base material layer 4, and the bottom material layer 5 into the tray in sequence, and then press and paste them at one time with a hot press and a cold press. The temperature of the hot press is 125°C, the pressure of the first stage is 1 Mpa, and the time is 5 minutes; the pressure of the second stage is 1 Mpa, and the time is 11 minutes; the pressure of the third stage is 1 Mpa, and the time is 13 minutes; One-stage pressure 4Mpa, time 5 min; second-stage pressure 5 Mpa, time 5 min; third-stage pressure 6 Mpa, time 4 min;

[0039] 2) UV tempering: The product treated in step 1) is coated by a paint coater, and the coating wheel is divided into a base coat and a top coat, and the coating amounts are 6.8±2g / ㎡ and 7.2±2g / ㎡ respectively, and then Tempering on the tempering line to remove ...

Embodiment 2

[0054] The hard multi-layer composite PVC floor is made by the following methods:

[0055] 1) Pressing: Put the wear-resistant layer 1, the color film layer 2, the middle material layer 3, the base material layer 4, and the bottom material layer 5 into the tray in sequence, and then press and paste them at one time with a hot press and a cold press. The temperature of the hot press is 135°C, the pressure of the first stage is 3 Mpa, and the time is 10 min; the pressure of the second stage is 3 Mpa, and the time is 18 min; One-stage pressure 8Mpa, time 10min; second-stage pressure 10Mpa, time 10min; third-stage pressure 10Mpa, time 10min;

[0056] 2) UV tempering: The product treated in step 1) is coated by a paint coater, and the coating wheel is divided into a base coat and a top coat, and the coating amounts are 6.8±2g / ㎡ and 7.2±2g / ㎡ respectively, and then Tempering on the tempering line to remove internal stress, hot water temperature: 100°C, cold water temperature: 20°C, ...

Embodiment 3

[0071] The hard multi-layer composite PVC floor is made by the following methods:

[0072] 1) Pressing: Put the wear-resistant layer 1, the color film layer 2, the middle material layer 3, the base material layer 4, and the bottom material layer 5 into the tray in sequence, and then press and paste them at one time with a hot press and a cold press. The temperature of the hot press is 145°C, the pressure of the first stage is 5 Mpa, and the time is 13 minutes; the pressure of the second stage is 5 Mpa, and the time is 21 minutes; the pressure of the third stage is 7 Mpa, and the time is 23 minutes; One-stage pressure 10Mpa, time 13 min; second-stage pressure 13 Mpa, time 15 min; third-stage pressure 14 Mpa, time 12 min;

[0073] 2) UV tempering: The product treated in step 1) is coated by a paint coater, and the coating wheel is divided into a base coat and a top coat, and the coating amounts are 6.8±2g / ㎡ and 7.2±2g / ㎡ respectively, and then Tempering on the tempering line to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com