Prefabricated special-shaped central column, assembled beam-column joint and its construction method

A technology of beam-column joints and prefabricated assembly, applied in the direction of columns, pillars, pier columns, etc., can solve the problems of no special-shaped concrete columns, inapplicability, low axial pressure, etc., and achieve the effect of improving self-resetting ability and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

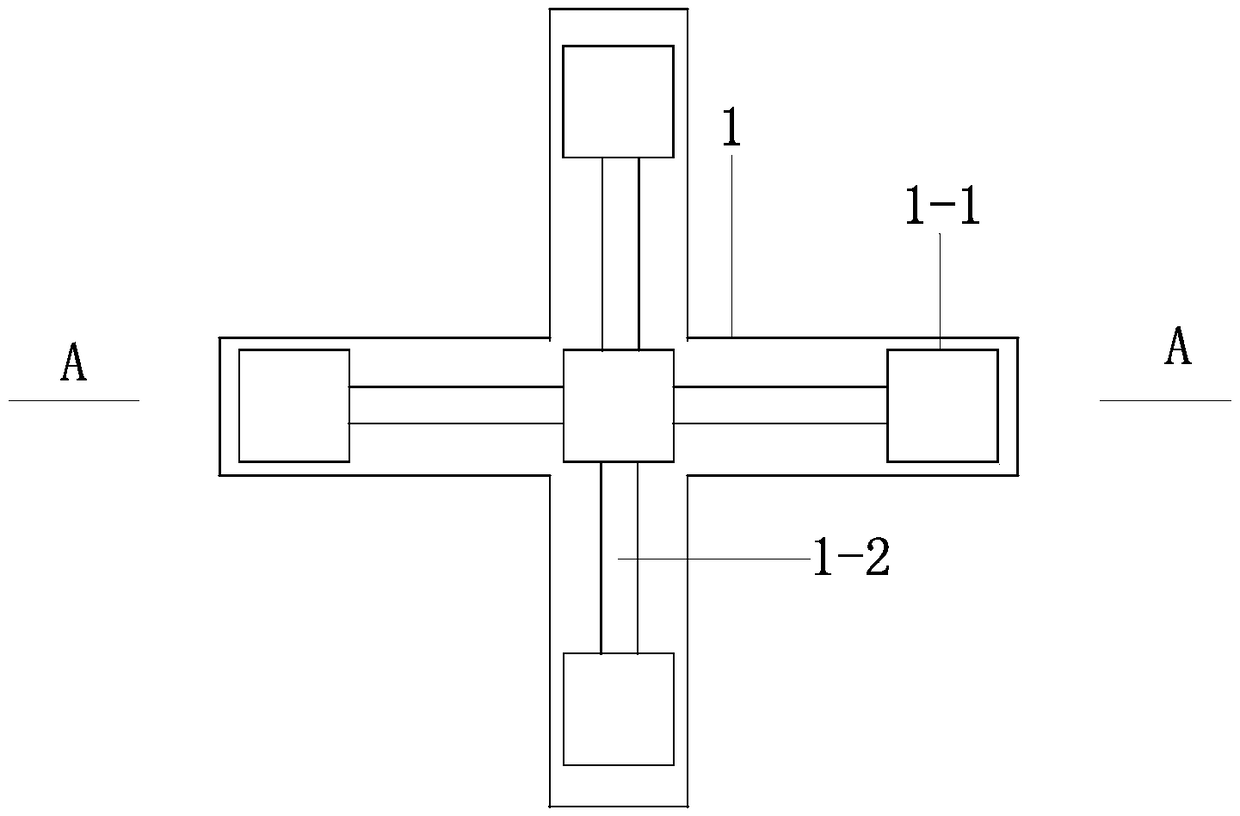

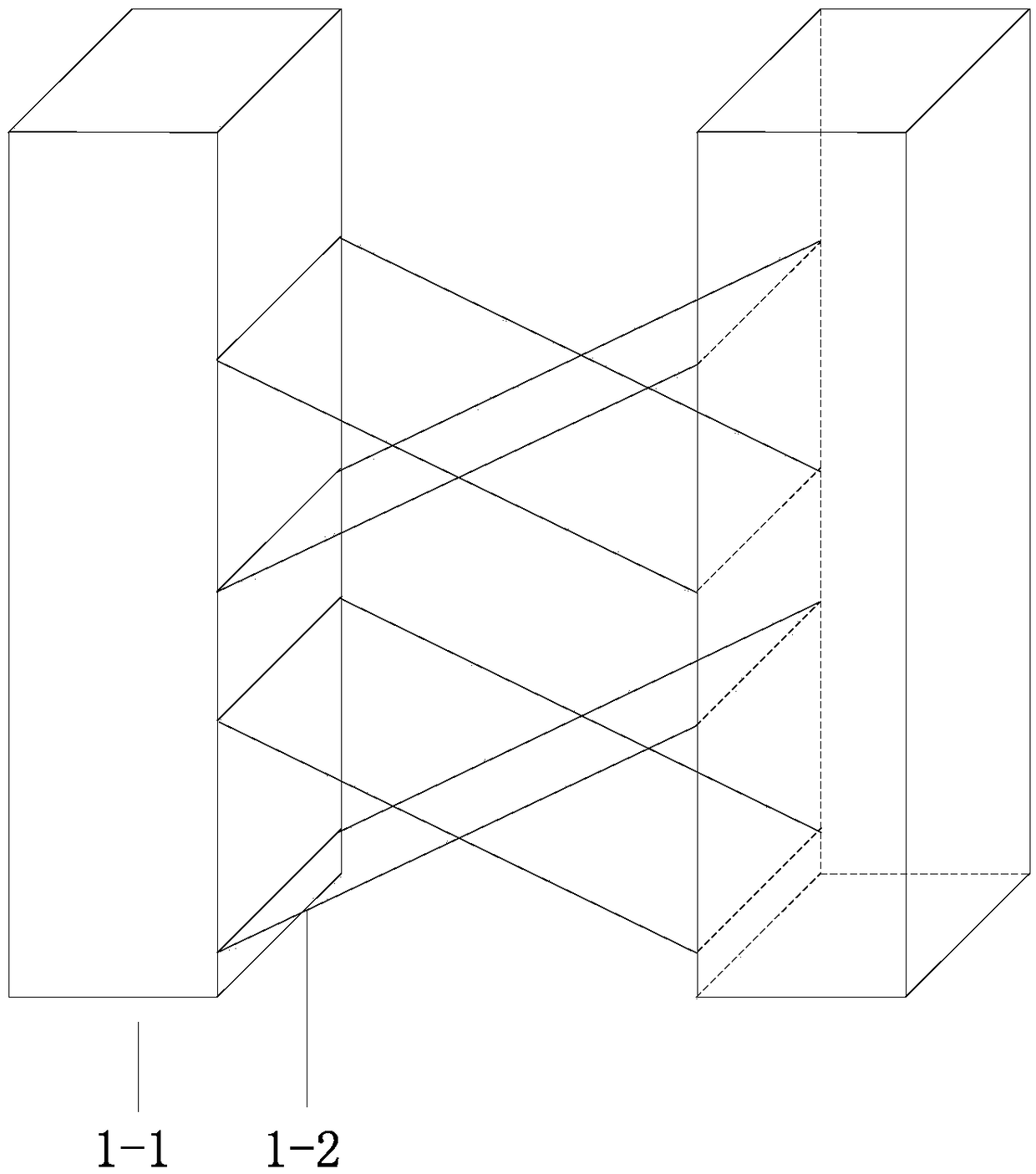

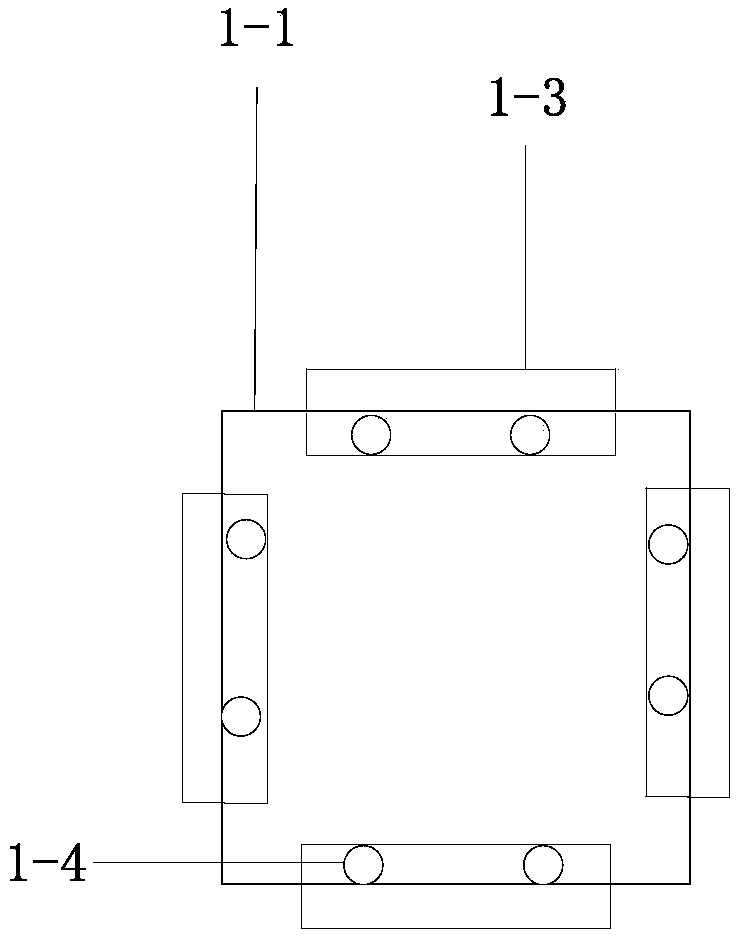

[0044] Embodiment 1: as Figure 1-6As shown, a special-shaped column is shaped like a "+", rectangular steel pipes (1-1) are arranged in its core area and limbs, and connecting members (1-1) are connected between adjacent rectangular steel pipes (1-1). 2) The connecting member adopts a symmetrical X-shaped unit, wherein the member and the horizontal plane form an angle of 30-45°, the connecting member adopts a corrugated steel plate or a strip, and the plane where the X-shaped unit is located is vertical to the vertical plane; the following The mechanical principle that the arrangement of the special-shaped central column connection member 1-2 can improve the shear bearing capacity is explained:

[0045] (1) with Figure 10 a is a comparative example, when the connecting member adopts vertical steel plate, that is, the plane where the steel plate is located is parallel to the vertical plane where the rectangular steel pipe is located, at this time, the shear bearing capacity ...

Embodiment 2

[0063] Embodiment 2 is different from Embodiment 1 in that, as Figure 7-8 As shown, steel plates (1-6) are embedded on both sides of the rectangular steel pipe (1-1) of the prefabricated column (1), and the steel plate (1-6) on the surface of the rectangular steel pipe (1-1) and the steel pipe connector (3) The lower steel plates (3-2) are connected by bolt assemblies (1-5), wherein the bolts are pre-embedded in the lower column. The steel pipe connector (3) is different from the separation method of the embodiment. In this embodiment, the steel pipe connector (3) corresponding to the rectangular steel pipe of the special-shaped center column is connected to the steel pipe (3-5) and the horizontal steel pipe (3-5). 4) Connect together; preferably, the connecting steel plate (3-5) is arranged on the lower side of the steel pipe connector and bolt holes are set, and the corresponding lower column is also embedded with bolts, and is fixed with the connecting steel plate through ...

Embodiment 3

[0070] Embodiment three, such as Figure 9 As shown, as in the second embodiment, the steel pipe connector adopts an integral type, the difference is that a horizontal steel plate (3-6) is also arranged on the steel pipe connector, and the horizontal steel plate (3-6) is arranged on the branch of the lower column. The outside of the steel pipe connector corresponding to the rectangular steel pipe of the limb, and there is no gap with the upper surface of the lower column; during construction, the prefabricated beam (2) is placed on the horizontal steel plate (3-6), and the end of the prefabricated beam touches the On the vertical steel plate of the steel pipe connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com