Spherical inspection well repairing machine

A technology for repairing machines and manholes, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of easy damage to the manhole head, and achieve the effects of convenient speed regulation, large thrust and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

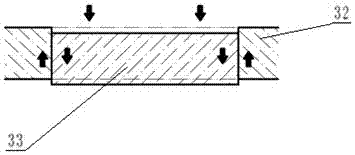

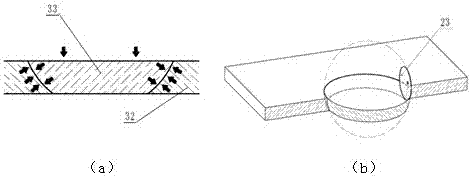

[0026] As attached figure 2 Attached Figure 8 As shown, a spherical well repairing machine includes a traction device and a working device. The traction device is composed of a trailer 21 and a tire 20; the working device includes a skeleton structure, a rotary roller device, an engine 1, a power control device, and a saw blade Device, hydraulic device;

[0027] The working device includes a fixed chassis 15, a rotating roller 16, a rotating disk 18, a horizontal moving bracket 19, a horizontal moving guide base 13, a vertical fixed rail base 3, and a guide rod 5; the vertical moving guide base 4 is connected with the vertical moving bracket 2, hydraulic The lifter 11 is connected with the horizontal moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com