Antineoplastic drug hydrate and preparation method thereof

An anti-tumor drug, hydrate technology, applied in the field of medicine, can solve problems such as inability to break through, and achieve the effects of improved solubility, high yield and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1: Preparation of olaparib 2.5 hydrate

[0060] (1) Take 100g of the crude product of olapanizan, add 1000ml of a mixed solution of dichloromethane / ethanol / water (10:10:1 by volume), heat and stir (30 rpm) to dissolve, decolorize with activated carbon, and filter with suction ;

[0061] (2) Lower the filtrate of step (1) to room temperature, slowly add (1.0 mL / min) 1000 ml of dichloromethane dropwise, and cool down (1°C every 10 minutes) to -5°C for crystallization;

[0062] (3) Insulate and stir until crystallization is complete, grow crystals for 1 hour, filter with suction, wash with water, and dry at 40°C to obtain 99.89g of white crystalline powder with a yield of 99.89% and a purity of 99.97%.

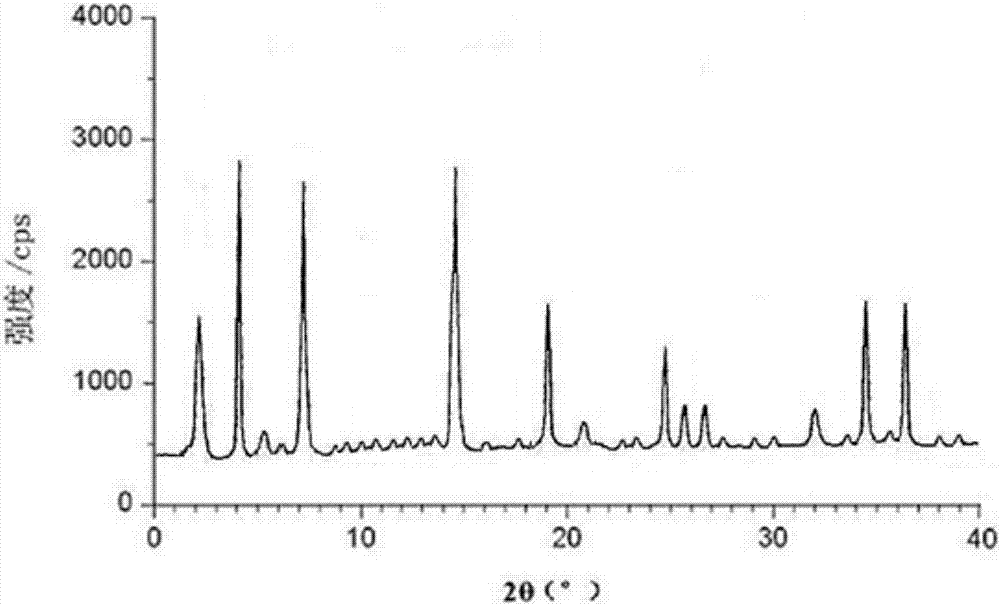

[0063] The X-ray powder diffraction spectrogram that the prepared white crystalline powder uses Cu-Kα ray measurement to obtain is shown in figure 1 .

Embodiment 2

[0064] Embodiment 2: Preparation of olaparib 2.5 hydrate

[0065] (1) Take 100 g of the crude product of olaparib, add 800 ml of a mixed solution of dichloromethane / ethanol / water (10:10:2 by volume), heat and stir (40 rpm) to dissolve, decolorize activated carbon, and filter with suction;

[0066] (2) Reduce the filtrate of step (1) to room temperature, slowly add (1.5mL / min) 400ml of dichloromethane dropwise, and cool down (3°C every 10 minutes) to -10°C for crystallization;

[0067] (3) Insulate and stir until crystallization is complete, grow crystals for 2 hours, filter with suction, wash with water, and dry at 45°C to obtain 99.88g of white crystalline powder with a yield of 99.88% and a purity of 99.98%.

[0068] The X-ray powder diffraction spectrum obtained by measuring the prepared white crystalline powder using Cu-Kα rays is similar to that of Example 1.

Embodiment 3

[0069] Embodiment 3: Preparation of olaparib 2.5 hydrate

[0070] (1) Take 100 g of the crude product of olaparib, add 900 ml of a mixed solution of dichloromethane / ethanol / water (10:10:1.5 by volume), heat and stir (30 rpm) to dissolve, decolorize activated carbon, and filter with suction;

[0071] (2) Lower the filtrate of step (1) to room temperature, slowly add (1.5mL / min) 720ml of dichloromethane dropwise, and cool down (the cooling range is 2°C every 10 minutes) to -7°C for crystallization;

[0072] (3) Insulate and stir until crystallization is complete, grow crystals for 2 hours, filter with suction, wash with water, and dry at 45°C to obtain 99.94g of white crystalline powder with a yield of 99.94% and a purity of 99.99%.

[0073] The X-ray powder diffraction spectrum obtained by measuring the prepared white crystalline powder using Cu-Kα rays is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com