Method for preparing electron-level trichlorosilane

A trichlorosilane, electronic-grade technology, applied in chemical instruments and methods, silicon compounds, halosilanes, etc., can solve the problems of high energy consumption in the purification process and unstable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

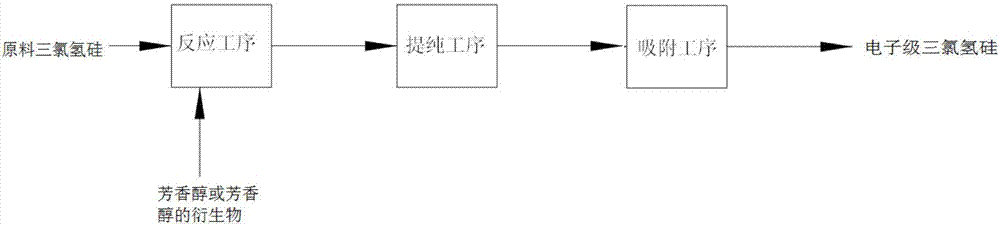

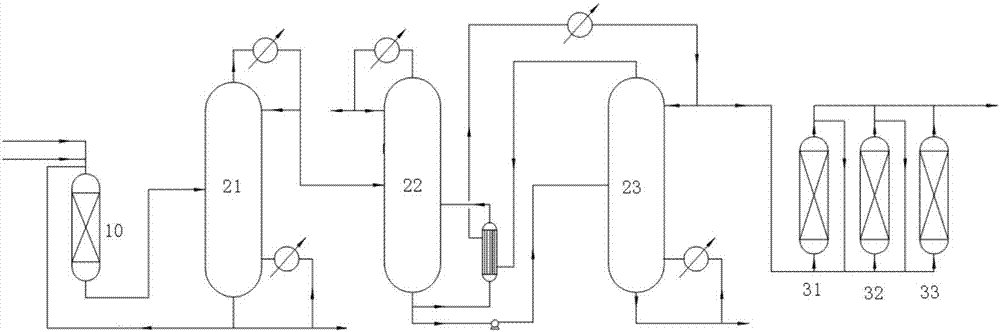

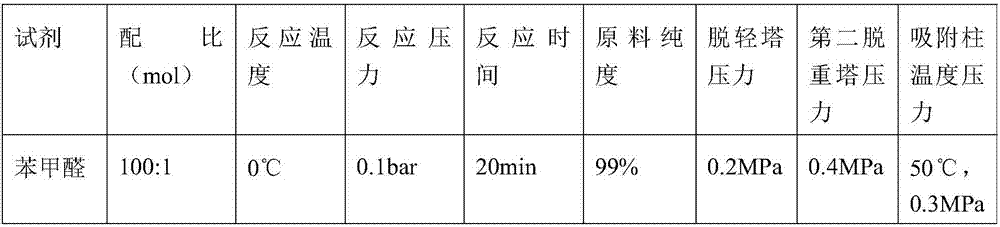

[0030] use figure 1 The process shown, using figure 2 The device shown, the specific test parameters are listed in Table 1.

[0031] Table 1

[0032]

[0033] Under the above conditions, the product trichlorosilane has a purity of 9N, a resistivity ≥ 1000Ω.cm, a B impurity content of 0.04ppb, a P impurity content of 0.07ppb, and an Al impurity content of 0.09ppb.

Embodiment 2

[0035] use figure 1 The process shown, using figure 2 The device shown, the specific test parameters are shown in Table 2.

[0036] Table 2

[0037]

[0038] Under the above conditions, the purity of the product trichlorosilane reaches 9N, the B impurity content is 0.01ppb, the P impurity content is 0.02ppb and the Al impurity is 0.07ppb.

Embodiment 3

[0040] use figure 1 The process shown, using figure 2 The device shown, the specific test parameters are shown in Table 3.

[0041] table 3

[0042]

[0043] Under the above conditions, the purity of the product trichlorosilane reaches 9N, the B impurity content is 0.04ppb, the P impurity content is 0.06ppb and the Al impurity is 0.11ppb.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com