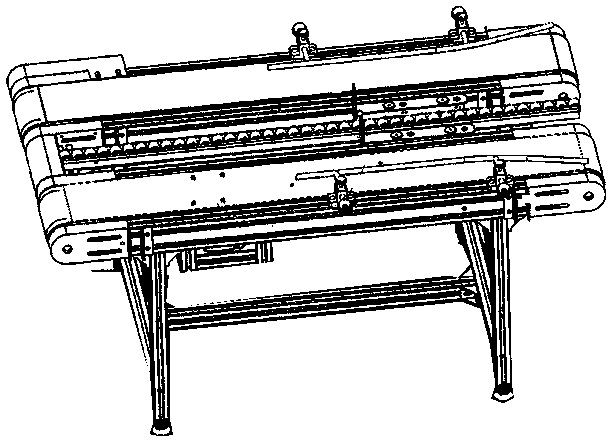

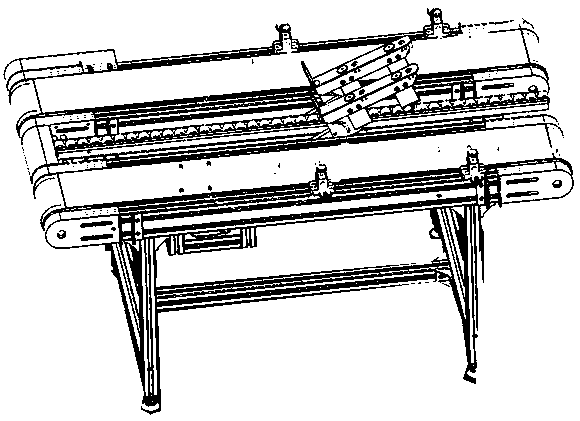

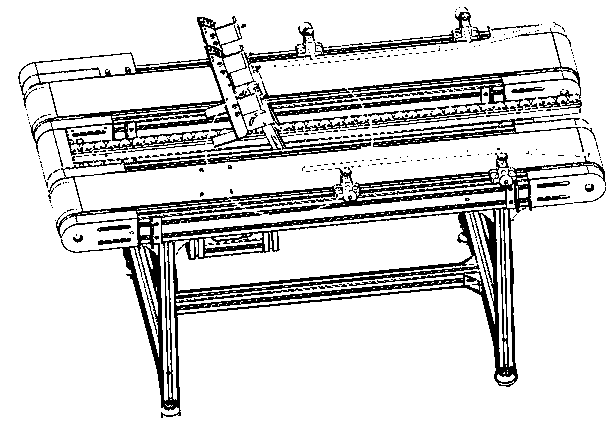

Turning mechanism for irregular packs

A turning mechanism and irregular technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that cigarette packs cannot be turned over, and achieve the effects of fast response, high precision and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0030] The technical scheme that the present invention solves the problems of the technologies described above is:

[0031] A turning machine design for irregular cigarette packs is provided, including the following steps:

[0032] S1, according to the structural characteristics of irregular cigarette packs, set the rules for matching irregular cigarette packs;

[0033] S2. Carry out the overall design of the mechanical structure of the flipping according to the functional requirements of the cigarette packet flipping;

[0034] S3, refine each substructure according to the complete flip action;

[0035] S4, according to the content of the IO signal, the turning machine performs corresponding operations,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com