Shape follow-up mold and method for additionally installing composite abrasion-resistant layer on metal component

A metal component and wear-resistant layer technology, applied in the field of conformal molds, can solve the problems of difficult forming, low yield and high processing cost, improve the ability to resist the impact of large particles, reduce the probability of dark cracks, and simplify installation. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

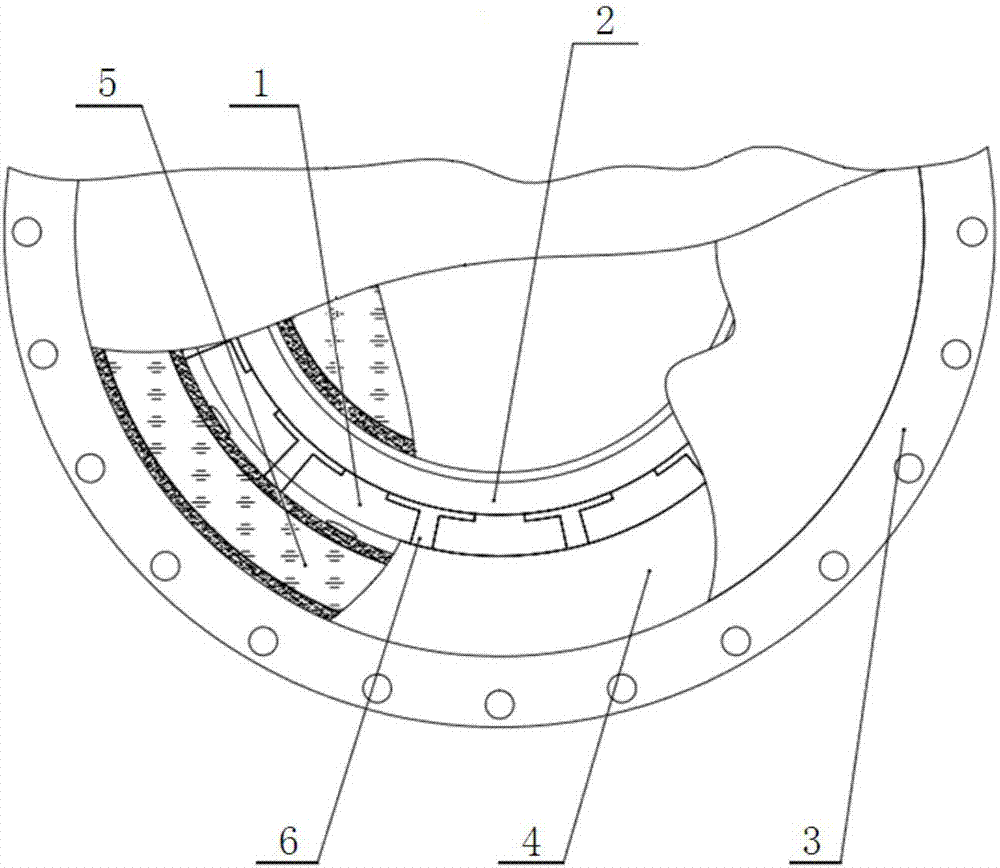

[0042] This embodiment is a method for installing a composite abrasion-resistant layer on a grinding roller, the method comprising the following steps:

[0043] 1) The prefabricated wear-resistant block 1 is made of structural ceramics; the structural ceramics can be composed of one or more of alumina ceramics, silicon carbide ceramics, and silicon nitride ceramics.

[0044] 2) fixing a plurality of prefabricated wear-resistant blocks 1 on the wear-resistant layer mounting surface of the grinding roller 2 through bolts;

[0045]3) Place the grinding roller 2 fixed with the prefabricated wear-resistant block 1 in the rigid forming cavity 3, and place it between the prefabricated wear-resistant block 1 and the rigid forming cavity 3 and between the grinding roller 2 and the rigid forming cavity 3 A plurality of flexible mold bags 4 made of rubber;

[0046] 4) Inject liquid fluid 5 into the flexible mold bag 4 through the liquid injection channel and discharge air, so that the f...

Embodiment 2

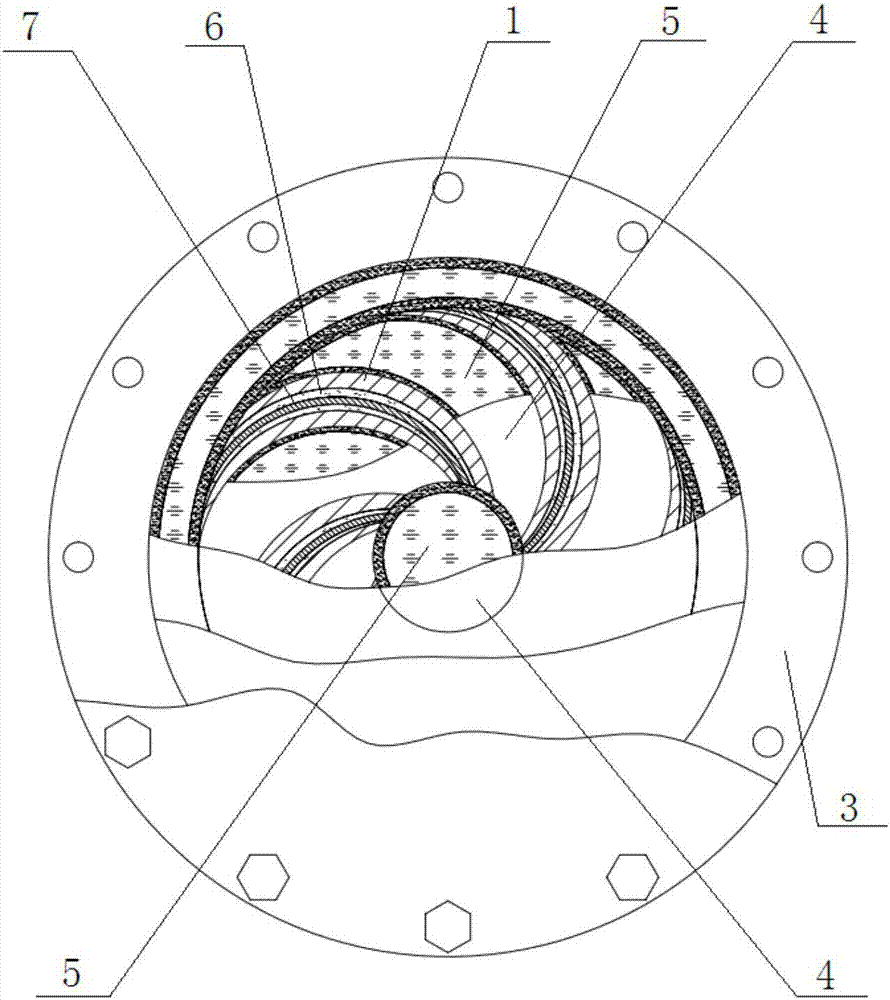

[0055] This embodiment is a method for installing a composite abrasion-resistant layer on the impeller of the pump body. The method includes the following steps:

[0056] 1) Prefabricated wear-resistant block 1 is made of a composite material of wear-resistant particles and thermosetting resin;

[0057] 2) Using an adhesive to fix a plurality of prefabricated wear-resistant blocks 1 on the wear-resistant layer mounting surface of the impeller 7;

[0058] 3) Place the impeller 7 fixed with the prefabricated wear-resistant block 1 in the rigid forming cavity 3, and place one or A plurality of flexible mold bags 4 made of elastic plastic material;

[0059] 4) Inject liquid fluid 5 into the flexible mold bag 4 through the liquid injection channel and discharge air, so that the flexible mold bag 4 fills the space between the prefabricated wear-resistant block 1 and the rigid molding cavity 3;

[0060] 5) Inject the wear-resistant filler 6 into the rigid molding cavity 3 through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com