Curing film for concrete with superplasticizer

A technology of concrete and water-reducing agent, which is applied in the field of curing film of adding water-reducing agent to concrete, can solve the problems of poor heat preservation effect, insufficient moisture and excessive moisture on the surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

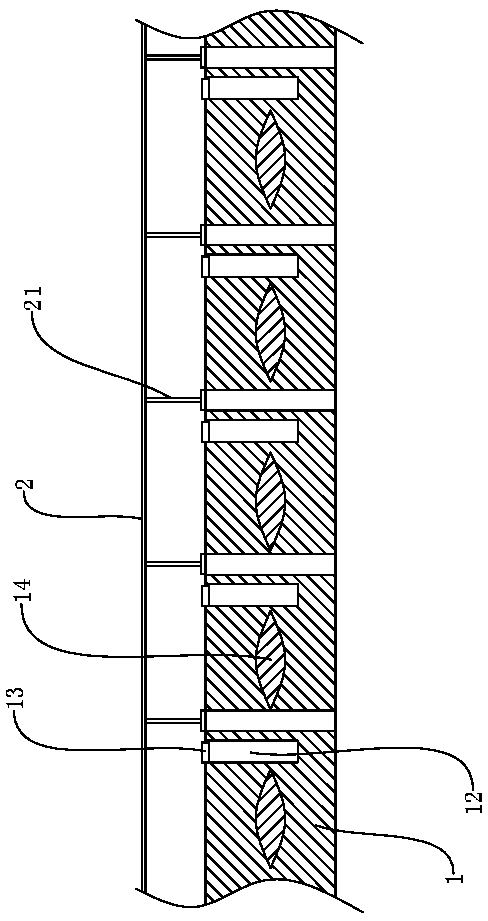

[0032] The curing film used for adding water-reducing agent to concrete includes a plastic film 1 and a transparent condensation film 2, and the condensation film 2 covers the surface of the plastic film 1. The material of the film 1 can be plastic, plastic or silica gel. In this embodiment, silica gel is selected. The material of the coagulation film 2 can be plastic film. The film 1 is opaque. After the film 1 is covered on the concrete surface, under the sunlight, because the condensation film 2 is transparent, it is equivalent to the direct exposure of the film 1 to sunlight, the temperature of the film 1 will rise, and the heat of the film 1 will be transferred to the concrete. This causes the temperature of the concrete to rise gradually.

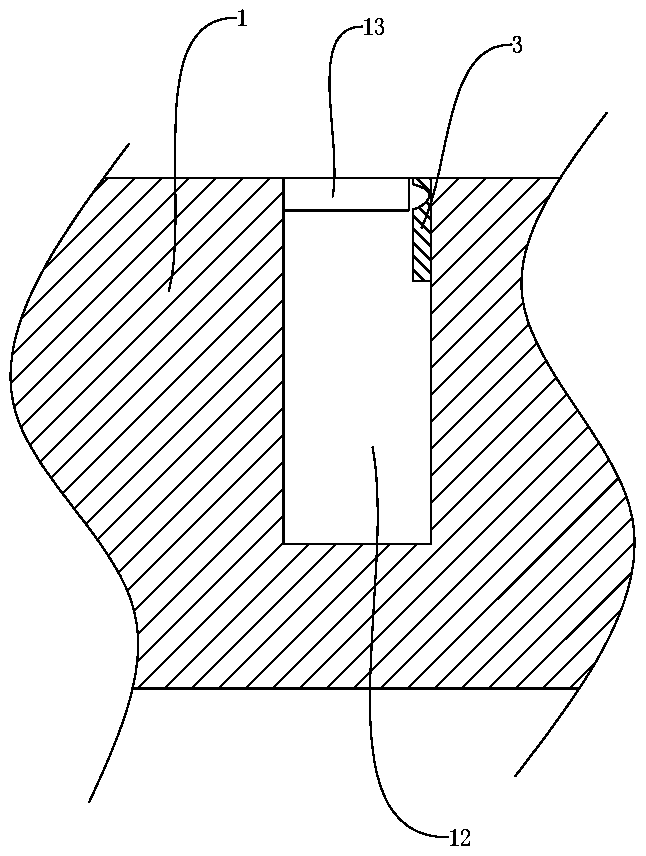

[0033] The mulch 1 is evenly provided with a plurality of storage tanks containing quicklime, the openings of the storage tanks 12 are provided with airbags 13 that can seal the opening of the storage tank 12, and the mulch 1 is provi...

Embodiment 2

[0035] Basic as attached figure 1 Shown: the curing film used for adding water reducing agent to concrete, including transparent mulch 1, which is made of transparent silica gel material, and the mulch film 1 made of silica gel is convenient for processing and storage, and can be folded well.

[0036] The mulch 1 is evenly provided with accommodating chambers and storage tanks 12 containing quicklime. The accommodating cavities and the storage tanks 12 are arranged alternately.

[0037] The opening of the storage tank 12 is provided with an air bag 13 that can seal the opening of the storage tank 12. The air bag 13 is made of plastic material, which has better elasticity.

[0038] Convex lenses 14 are arranged in the accommodating cavities, and the convex lenses 14 here are made of glass. Of course, the material of the convex lens 14 can also be made of transparent plastic, but in consideration of cost, glass is used in this embodiment.

[0039] The mulch film 1 is provided ...

Embodiment 3

[0043] Compared with Example 1, the only difference is that there is an accommodation chamber for accommodating the light concentrator in the mulch film, the middle of the accommodation chamber is thick and the edge is thin, the accommodation chambers are connected to each other, and the accommodation chamber is filled with clean water. Transparent liquids such as chloroform and alcohol can also be used to fill the containing cavity, but in a comprehensive comparison, the cost of clear water is the lowest, so clear water is selected in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com