Multi-stage cylinder line marking and drilling safety tool, multi-stage cylinder line marking method and multi-stage cylinder drilling machining method

A technology for cylindrical workpieces and cylinders, which is applied in the field of multi-level cylindrical scribing and drilling safety tooling and scribing and drilling processing. It can solve the problems of multi-level cylindrical workpiece center of gravity deviation, low processing efficiency, and potential safety hazards, and achieve Reliable assurance of drilling and tapping accuracy, improved processing efficiency, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

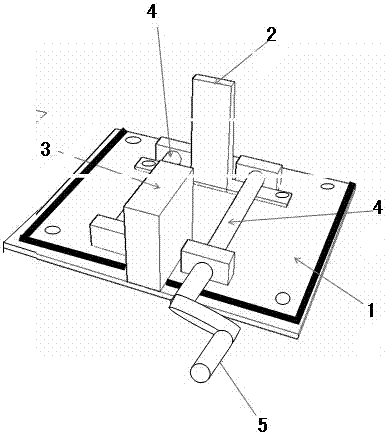

[0018] As shown in the figure, the multi-stage cylinder marking and drilling safety tooling includes a horizontal bottom plate 1; A moving clamping mechanism 3; a pair of parallel horizontal rollers 4 are installed on both sides of the bottom plate, and the two ends of the horizontal rollers are installed on the support through bearings, and at least one end of the horizontal roller 4 is installed with a drive that can drive the horizontal roller. The rocker 5 that the roller rotates; the outer circumference of the cylindrical workpiece can be placed between two horizontal rollers 4 and is tangent to the horizontal rollers, and the axial ends of the cylindrical workpiece can be held by the opposite clamping mechanism 3 and the support baffle 2 Axial clamping fixes or releases. The clamping mechanism adopts a thrust cylinder pneumatic clamping device.

[0019] The multi-stage cylinder marking and drilling processing method of the embodiment of the present invention adopts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com