Five-station small drilling and tapping integrated machine

An all-in-one, five-station technology, applied in the field of mechanical processing, can solve problems such as unreasonable resource allocation, low production efficiency, and inability to process at the same time, and achieve the effects of easy adjustment and modification, high production efficiency, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

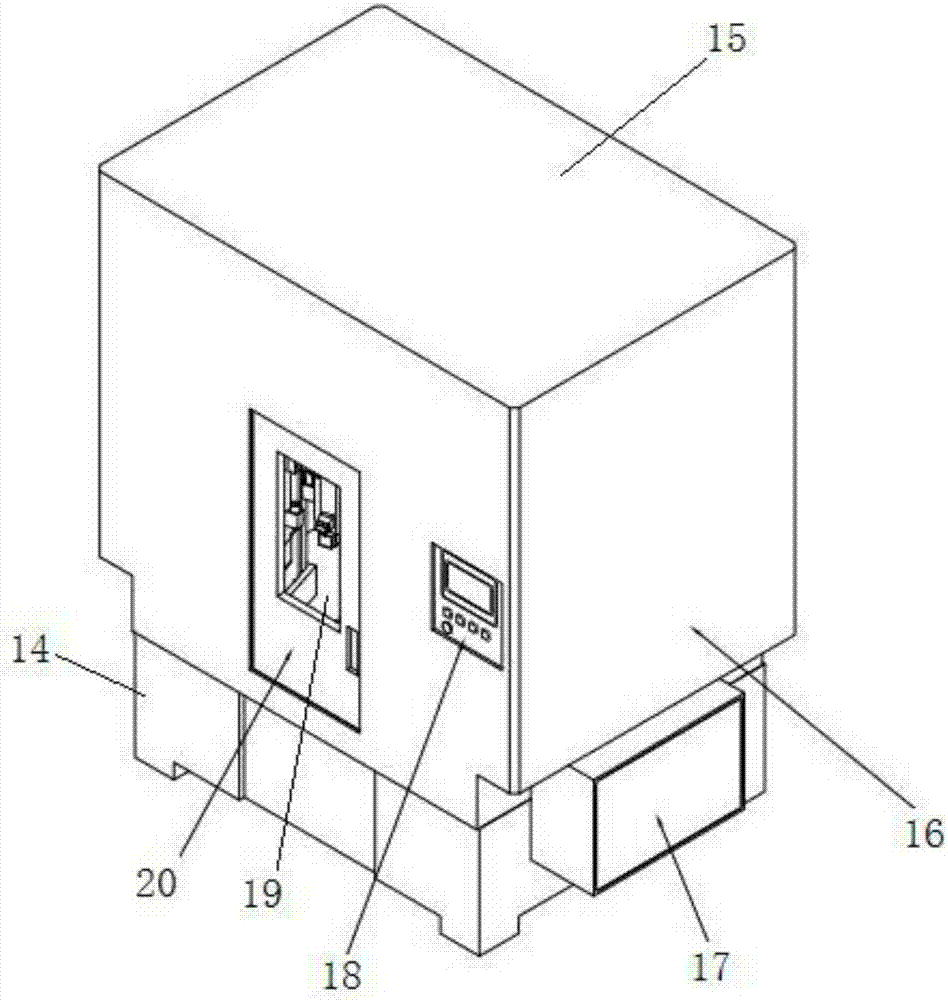

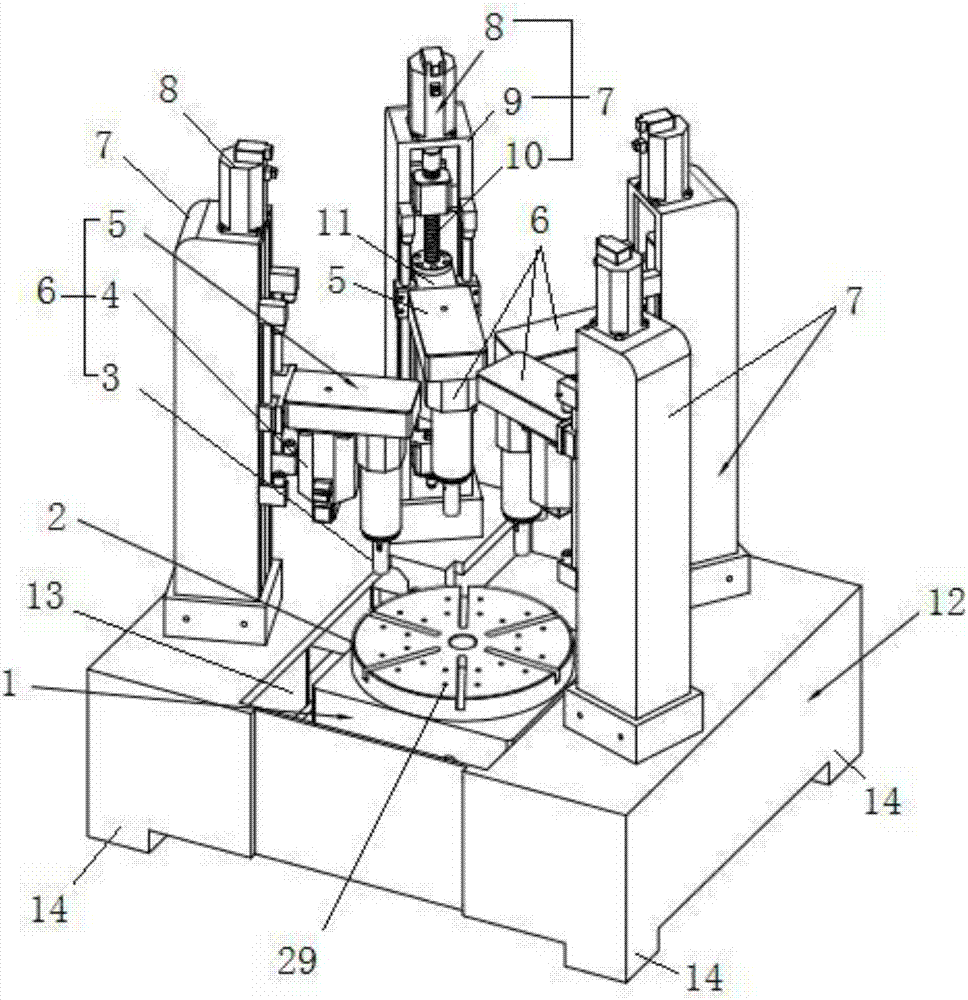

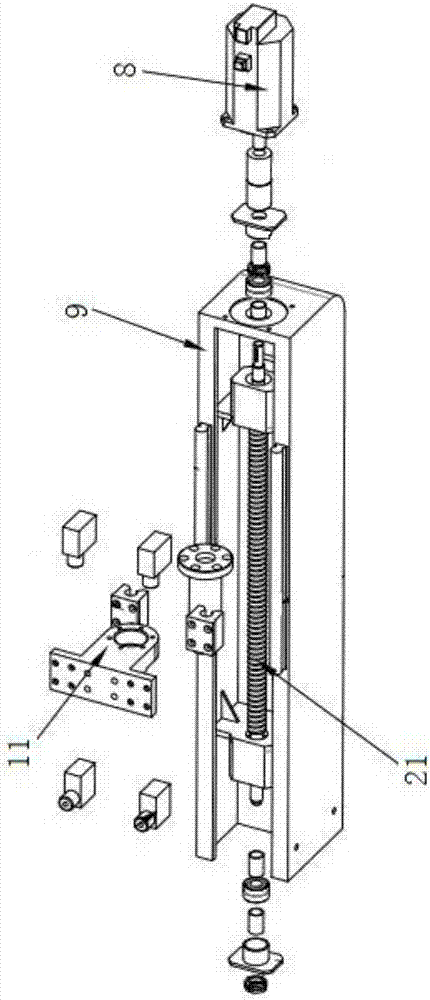

[0023] Depend on Figure 1-Figure 6 A five-station small drilling and tapping integrated machine is shown, which includes a machine base 12, which is provided with a rotary table and several longitudinal feed mechanisms 7 arranged at intervals around the rotary table.

[0024] The rotary table includes an indexing plate 2 and a rotary transmission mechanism that drives the indexing plate 2. The indexing plate 2 is a disc arranged horizontally, and the indexing plate 2 is provided with a plurality of stations. Specifically, in this embodiment, the indexing plate The disc 2 is provided with five stations, and the five stations are evenly distributed along the circumference around the central axis of the indexing disc 2. The distance between the two adjacent stations in the circumferential direction is 72°, and each station is correspondingly equipped with a number of The threaded hole 29 for installing the fixture, the workpiece is installed on the fixture for processing.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com