Full-automatic drainage type centrifugal oil purification device

A centrifugal and fully automatic technology, applied in the direction of centrifuges, centrifuges with rotating drums, etc., can solve the problems that the drainage efficiency of oil purification equipment cannot be guaranteed, the working efficiency of oil purification equipment is affected, and the actual production cannot be satisfied. Achieve the effects of cost saving, simple operation and high oil purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

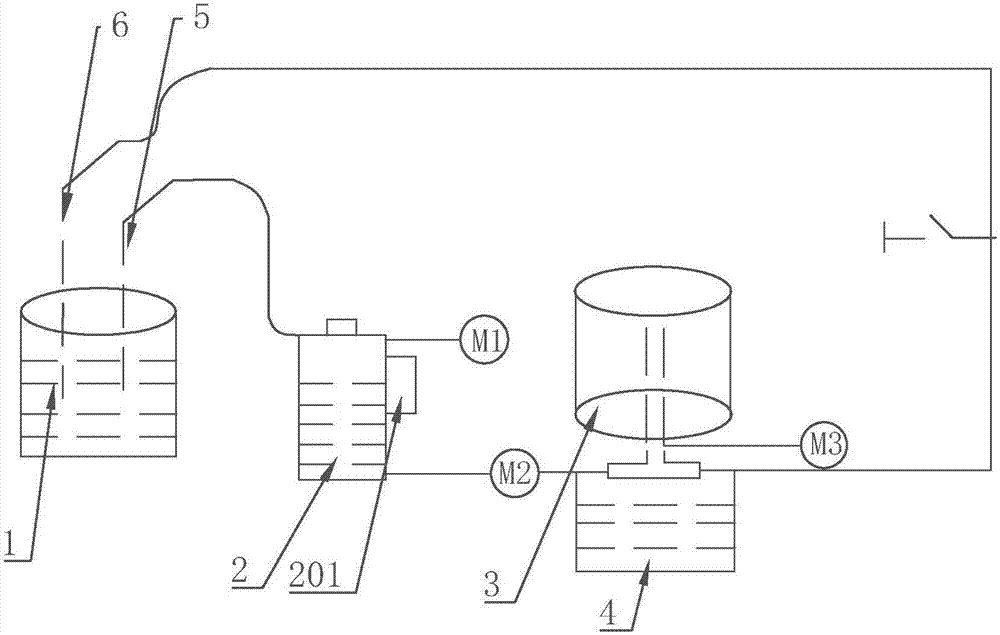

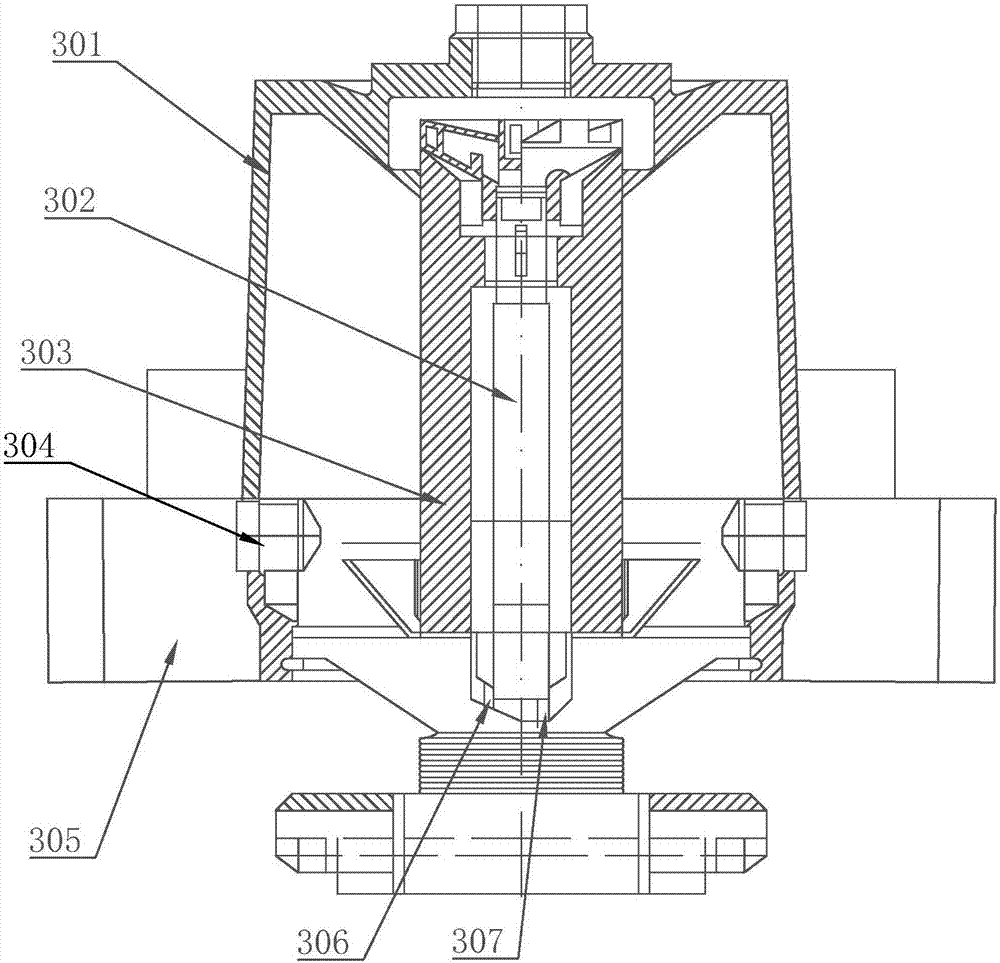

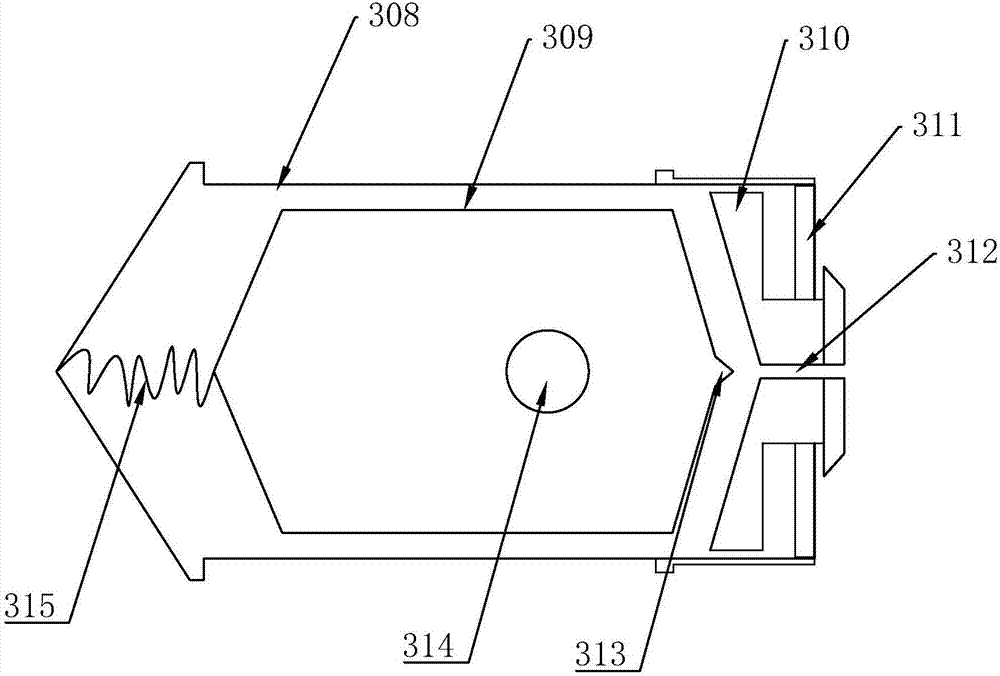

[0028] like Figure 1-4 As shown in the figure, a fully automatic drainage type centrifugal oil purifier of the present invention includes an oil tank 1, a dirt holding box 4 and a centrifugal barrel assembly 3, an auxiliary oil tank 2 is arranged between the oil tank 1 and the centrifugal barrel assembly 3, and the centrifugal barrel assembly 3 Connected to the engine, the auxiliary oil tank 2 and the centrifugal barrel assembly 3 are respectively connected to the booster pump, and the auxiliary oil tank 2 is also connected to the vacuum pump. The centrifugal barrel assembly 3 includes a centrifugal barrel body 301, and the centrifugal barrel body 301 is installed on the central shaft 302. A plurality of bowl-shaped discs 303 placed vertically concentrically upward are installed on the 302. The discs are provided with diversion grooves. The bottom of the centrifugal bucket body 301 is provided with a sewage outlet. The bottom end is provided with an oil inlet 306 and an oil r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com