A kind of preparation method of cigarette mouth stick additive and its application in filter

A technology of additives and cigarette filter rods, applied in the application, smoke oil filter, tobacco and other directions, to achieve the effects of easy implementation, simple process and outstanding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

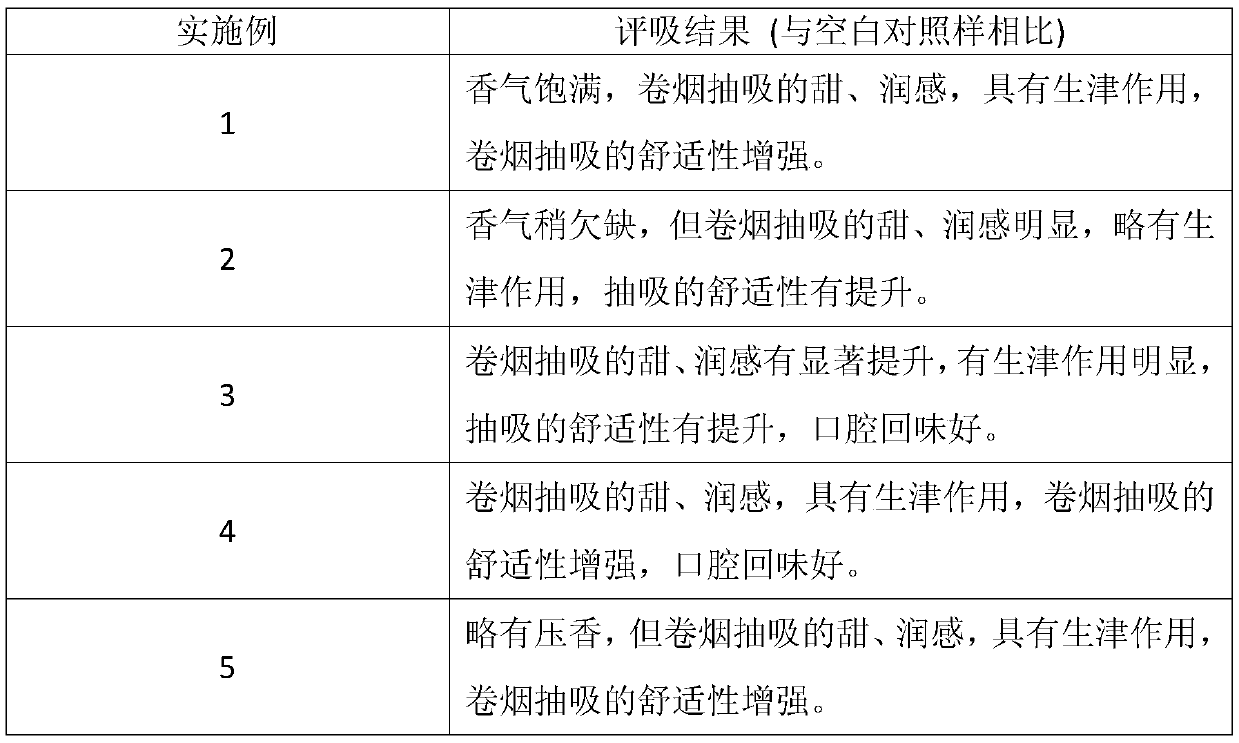

Examples

Embodiment 1

[0022] The whole plant of Xueshan licorice was washed, dried at 70°C and crushed to 80 mesh. Take the pulverized snow mountain licorice powder, use dimethyl ether as subcritical extractant, glycerol triacetate as entrainer, and carry out subcritical extraction at a temperature of 30°C and an extraction pressure of 2.5Mpa; the extractant dimethyl ether The amount is 10 times of snow mountain licorice weight. The entraining agent triacetin consumption is 4 times of the weight of Snow Mountain Glycyrrhizae. After the extraction is finished, the extraction mixture enters the separation tank, and the extraction solvent dimethyl ether is separated by the principle of vacuum evaporation to obtain the glycerol triacetate extract solution containing licorice, and then the licorice containing licorice Dilute the triacetin extract solution by 10 times, make it fully dissolved, cool to room temperature, transfer to -15°C refrigerator to freeze for 10 hours, filter and separate the clear ...

Embodiment 2

[0024] The whole plant of Xueshan licorice was washed, dried at 75°C and crushed to 90 mesh. Take the pulverized snow mountain licorice powder, use dimethyl ether as the subcritical extractant, glycerol triacetate as the entrainer, and carry out subcritical extraction at a temperature of 25°C and an extraction pressure of 2.8Mpa; the extractant dimethyl ether The amount is 12 times of snow mountain licorice weight. The entraining agent triacetin consumption is 5 times of the weight of Snow Mountain Glycyrrhizae. After the extraction is completed, the extraction mixture enters the separation tank, and the extraction solvent is separated by the principle of vacuum evaporation to obtain the glycerol triacetate extract of Snow Mountain Glycyrrhizae. After recovering the dimethyl ether, the Glycyrrhizae triacetin extract was diluted 10 times with glycerol triacetate to make it fully dissolved, then cooled to room temperature, transferred to -18°C refrigerator for 10 hours, and fil...

Embodiment 3

[0026] The whole plant of Xueshan licorice was washed, dried at 78°C and crushed to 95 mesh. Take the crushed snow mountain licorice powder, use dimethyl ether as the subcritical extractant, glycerol triacetate as the entrainer, and carry out subcritical extraction at a temperature of 28°C and an extraction pressure of 2.9Mpa; the extractant dimethyl ether The amount is 15 times of snow mountain licorice weight. The entraining agent triacetin consumption is 5 times of the weight of Snow Mountain Glycyrrhizae. After the extraction is completed, the extraction mixture enters the separation tank, and the extraction solvent is separated by the principle of vacuum evaporation to obtain the glycerol triacetate extract of Snow Mountain Glycyrrhizae. After recovery of dimethyl ether, the Glycyrrhiza Glycyrrhizae triacetin extract was diluted 8 times with glycerol triacetate to make it fully dissolved, then cooled to room temperature, transferred to -20°C for 8 hours, and centrifuged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com