Preparation method of lactic acid bacterium protein raw material with high content of small peptide and application thereof

A technology for protein raw materials and lactic acid bacteria, applied in the field of preparation of lactic acid bacteria protein raw materials, can solve the problems of difficulty in direct use, shortage of protein raw materials, unfavorable liquid transportation, etc., and achieve the effects of increasing daily weight gain, reducing feed costs and relieving economic pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

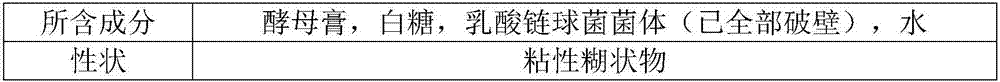

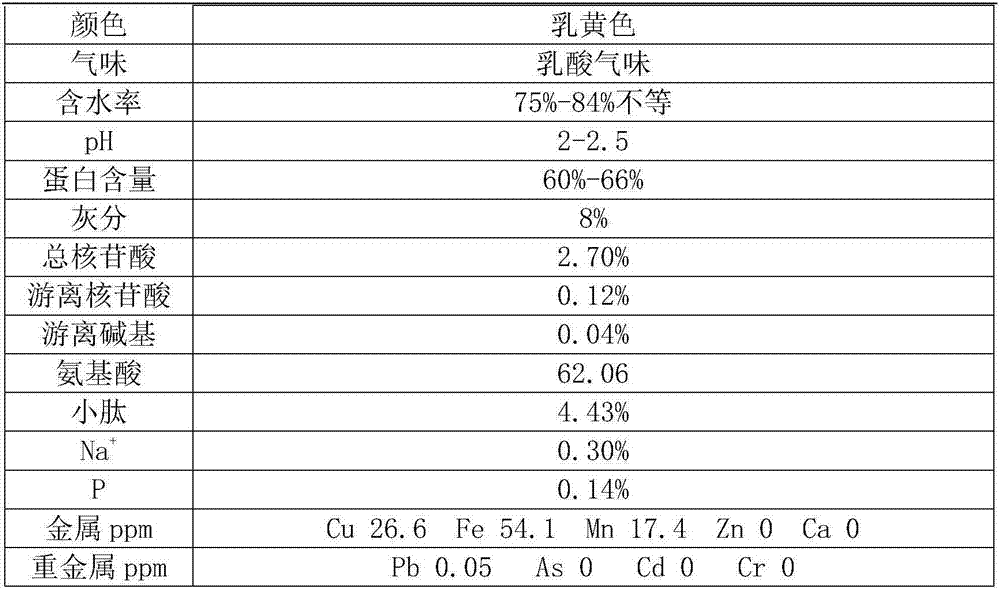

Image

Examples

Embodiment

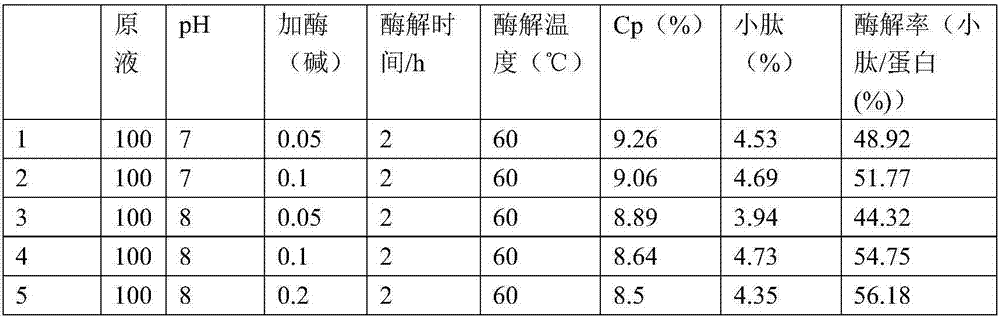

[0022] Enzyme test

[0023] Alkaline protease hydrolysis experiment data are shown in Table 1

[0024]

[0025] Table 1 Alkaline protease hydrolysis experiment data table

[0026] Trypsin hydrolysis experiment data are shown in Table 2

[0027]

[0028] Table 2 trypsin digestion experiment data table

[0029] Conclusion: From the above experiments, it can be seen that the enzymatic hydrolysis effect of trypsin is better than that of alkaline protease. Prolonging the enzymatic hydrolysis time can further improve the enzymatic hydrolysis rate, but the increase is not large.

[0030] animal testing

[0031] In the enzymatic hydrolysis test, 0.05% of trypsin was selected for enzymatic hydrolysis pH 7.5, and the enzymatic hydrolysis temperature was 50° C. for 2 hours. A batch of finished products are dried and tested on weaned piglets.

[0032] The experimental diet formula is shown in Table 3:

[0033]

[0034] Table 3 Test diet formula table

[0035] Animal test r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com