Wuyi rock tea making device and production process thereof

A manufacturing device and technology of rock tea, applied in the field of Wuyi rock tea manufacturing device, can solve the problems of unfavorable brewing, low work efficiency, low efficiency, etc., avoid the loss of nutrients, improve water residue and aroma, and be convenient to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

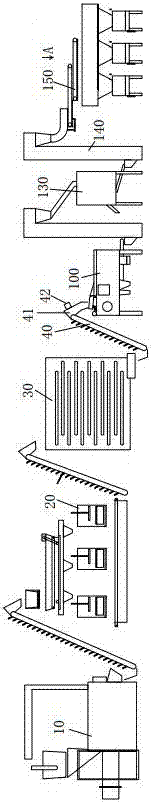

[0035] refer to Figure 1 to Figure 12

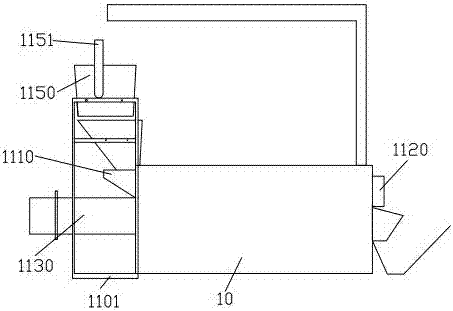

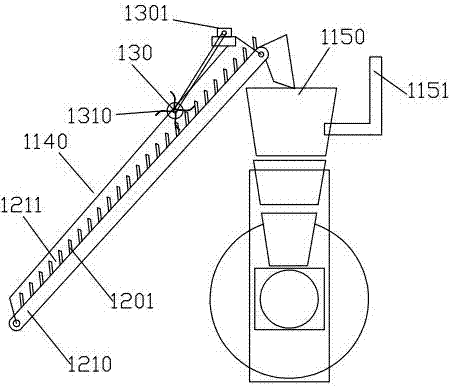

[0036] A manufacturing device for Wuyi rock tea, comprising a de-greening tank 10, a kneading device 20, a drying device 30, a wind screening device 100, an electrostatic destemming device 130, and a material distribution and screening device 150 arranged in sequence. The greening tank 10 mainly conducts electric heating in the greening drum to destroy and passivate the oxidase activity in the fresh leaves through high temperature, inhibit the enzymatic oxidation of tea polyphenols in the fresh leaves, evaporate part of the water in the fresh leaves, and make the tea soft and easy to knead Forming, kneading device 20 is to utilize pressure to knead the tea leaves after f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com