Coagulated cheese flavor fermented milk and preparing method thereof

A technology of coagulation type, fermented milk, applied in the direction of dairy products, bacteria used in food preparation, milk preparations, etc., can solve the problems of affecting the taste and texture of products, the taste of cheese is not obvious, the taste is powdery, etc. Fine and smooth texture and taste, improve water retention and stability, enhance the effect of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

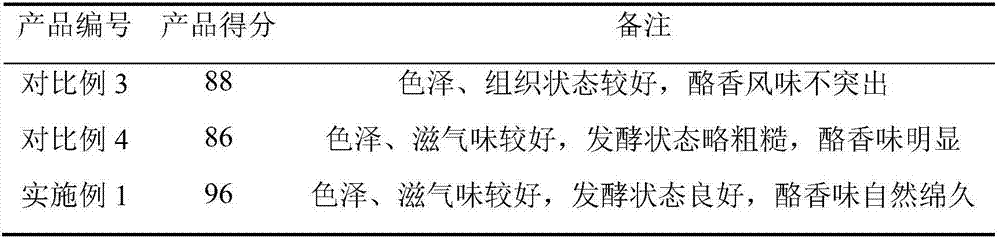

Examples

Embodiment 1

[0030] A solidified cheese-flavored fermented milk, which is composed of the following raw materials in parts by weight: 80 parts of raw milk, 0.005 parts of fermented strains, 0.5 parts of whey protein powder, 0.1 part of tremella polysaccharide, 5 parts of white sugar, 0.5 parts of cheese powder, Edible salt 0.01 part.

[0031] The fermentation strains are Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris.

[0032] The preparation method of described coagulated cheese flavor fermented milk comprises the following steps:

[0033] 1) Ingredients: Take part of the liquid milk and heat it up to 45-50°C, dry mix whey protein powder, white fungus polysaccharide and part of the white sugar, put it into the part of the liquid milk that has been heated up in the high-speed shear tank, mix well, and then put the remaining White sugar, cheese powder and edible salt are mixed evenly and added to part of the heated liquid milk, stirred for 15 minutes to fully disso...

Embodiment 2

[0038]A solidified cheese-flavored fermented milk, which consists of the following raw materials in parts by weight: 90 parts of raw milk, 0.005 parts of fermented strains, 2.0 parts of whey protein powder, 1.0 parts of tremella polysaccharide, 10 parts of white sugar, 3 parts of cheese powder, Edible salt 0.1 part.

[0039] The fermentation strains are Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris.

[0040] The preparation method of the flavored fermented milk is the same as in Example 1.

Embodiment 3

[0042] A solidified cheese-flavored fermented milk, which is composed of the following raw materials in parts by weight: 82 parts of raw milk, 0.005 parts of fermented strains, 0.8 parts of whey protein powder, 0.3 parts of tremella polysaccharide, 6 parts of white sugar, 1 part of cheese powder, Edible salt 0.03 parts.

[0043] The fermentation strains are Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris.

[0044] The preparation method of the flavored fermented milk is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com