A mmc circulation control method with a single bridge arm sensor

A circulating current control and sensor technology, which is applied in the direction of converting irreversible DC power input to AC power output, output power conversion device, climate sustainability, etc., to reduce design complexity and power loss, and achieve double the bridge arm. The effect of frequency circulation suppression and quantity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

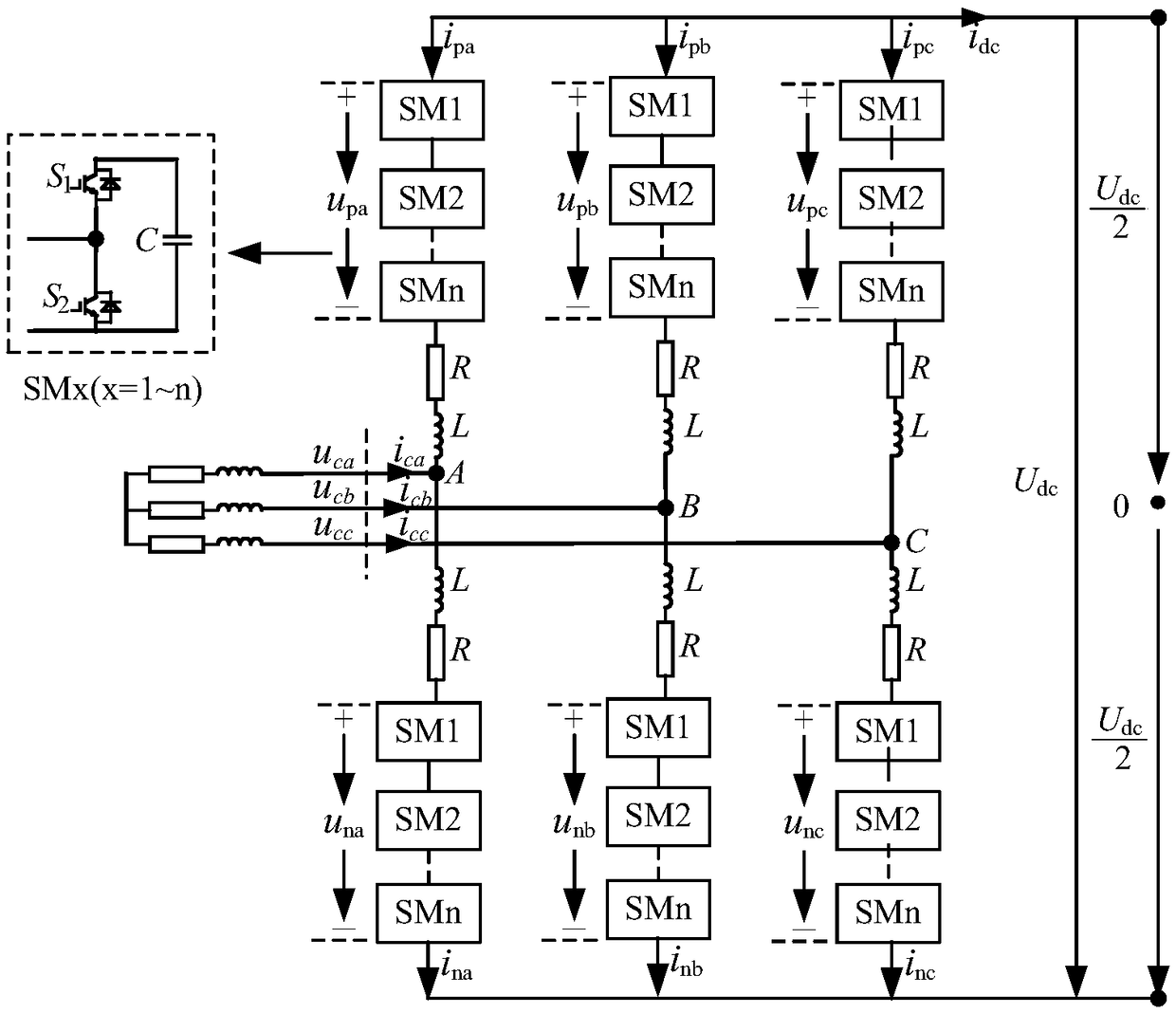

[0034] figure 1 Shown is the structure diagram of the three-phase MMC system used in the present invention. Each phase of the modular multi-level structure is composed of upper and lower bridge arms, which can be regarded as two star cascaded SVGs connected in parallel at the input ends and connected in series at the output ends. Resistive load. In the figure, U dc Indicates the MMC DC voltage source, I dc is the DC bus current, u px and u nx (x=a, b, c, the same below) are the output voltages of the upper and lower bridge arms respectively, u cx is the output voltage of the inverter side, i px and i nx are the upper and lower arm currents respectively, i cx is the AC output current, R and L are the bridge arm resistance and inductance respectively, R o and L o are the resistive and inductive loads on the inverter side, respectively. The expressions of the bridge arm output voltage and the bridge arm current are as follows:

[0035]

[0036] Among them, u ex is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com