Linear vibrator

A linear vibrator and coil technology, applied in electrical components, electromechanical devices, etc., can solve the problems of shortening the service life of the motor, difficult to touch the screen, and achieve the effect of fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

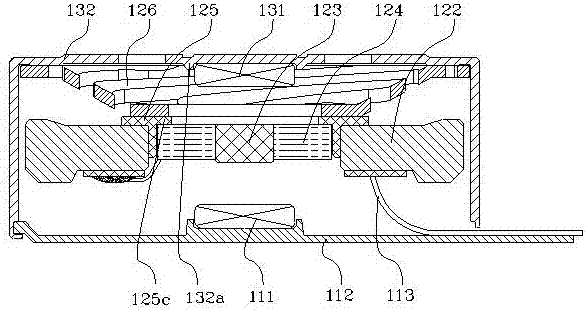

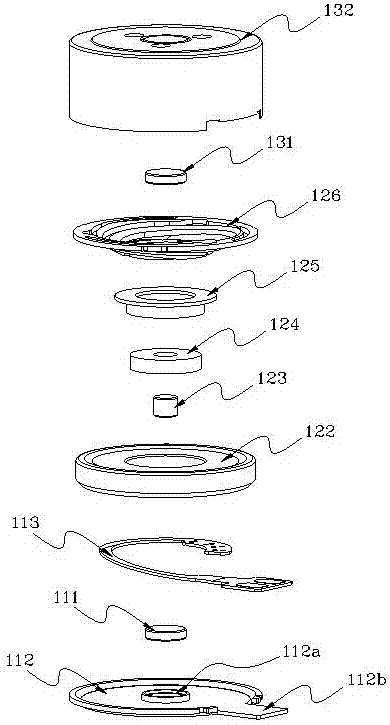

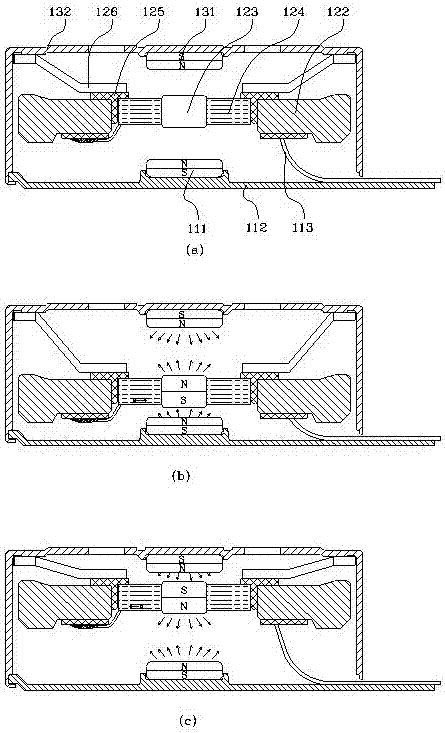

[0029] refer to figure 1 , figure 2 , the linear vibrator of the present invention is made up of the following components: the upper casing 132 that protects the internal components of the linear vibrator and provides space; The electromagnetic force produced by the electromagnet interacts; the upper casing 132 and the first permanent magnet 131 form the upper fixed part 130, and the upper fixed part 130 is connected with the elastic part 126 of the vibrating part 120; the vibrating part 120 includes an iron core support 123, a coil 124, mass body 122, metal plate 125, elastic component 126, the outer diameter of the iron core support 123 is surrounded by the coil 124, the elastic component 126 is connected with the vibrating part 120 through the metal sheet 125; matches with the upper casing 132 to protect the lower part of the internal components Case 112; the second permanent magnet 111 interacting with the electromagnet of the vibrating part 120 is set in the lower case ...

Embodiment 2

[0039] In this embodiment, the metal plate 325 connecting the elastic member 326 and the mass body can be used as a bracket, and the iron steel plate is made into the metal plate 325 by stamping equipment. The metal plate 325 has an annular flat part 325a and A cylindrical protruding part 325b, the elastic member 326 is fixed on the upper surface of the circular planar part 325a, and the cylindrical protruding part 325b is inserted into the inner ring of the coil 324 as a metal body. The cylindrical protruding portion 325b is inserted into the air-core coil 324 , and the same effect can be achieved without inserting the iron core support 123 . In order to maximize the strength of the electromagnet, the height of the cylindrical protrusion 325b ≥ the height of the hollow coil 324 . The coil 324 generates an electromagnetic force in the direction of vertical vibration, and the cylindrical protrusion 325b of the metal plate 325 forces this electromagnetic force in one direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com