Light-emitting device with beam shaping structure and manufacturing method of light-emitting device

A light-emitting device and structure adjustment technology, which is applied to electrical components, electric solid-state devices, circuits, etc., can solve the problems of complicated manufacturing process, increased production cost, and decreased luminous efficiency of the package, and achieve simple manufacturing process, reduced loss, and increased luminous angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

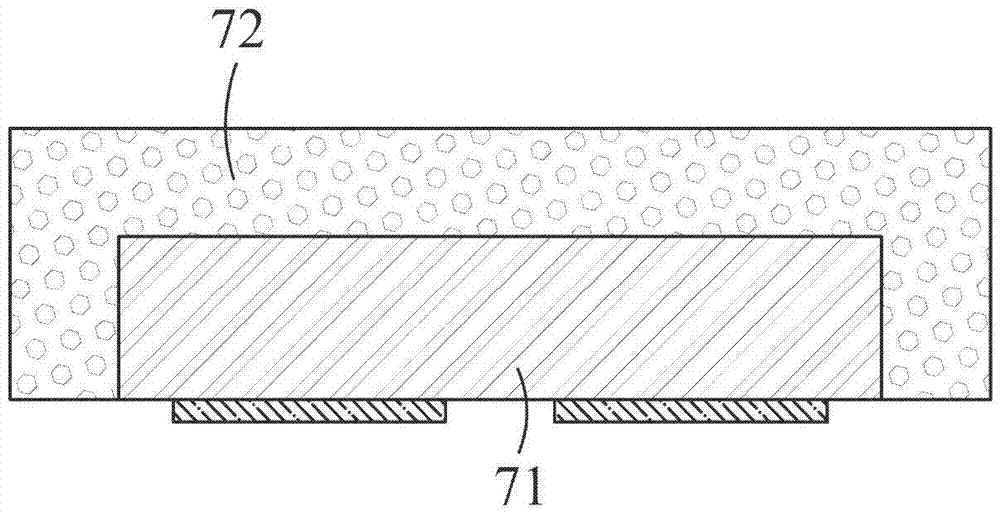

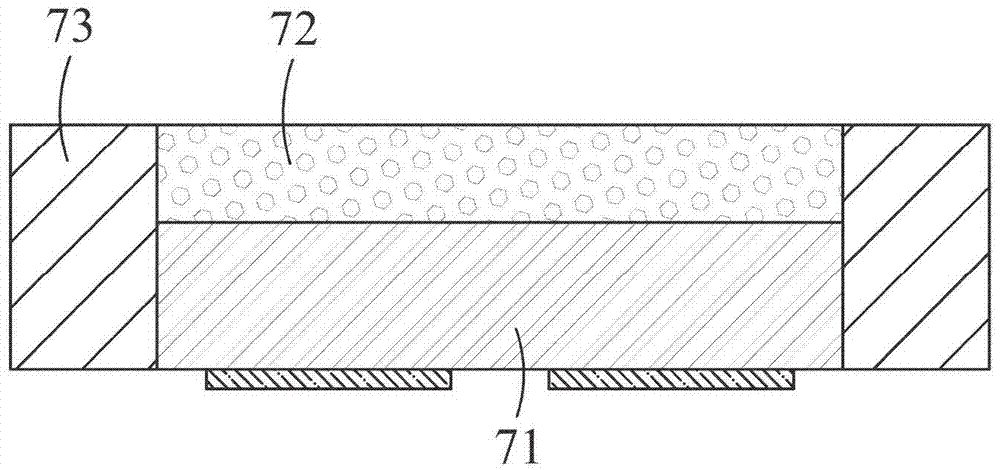

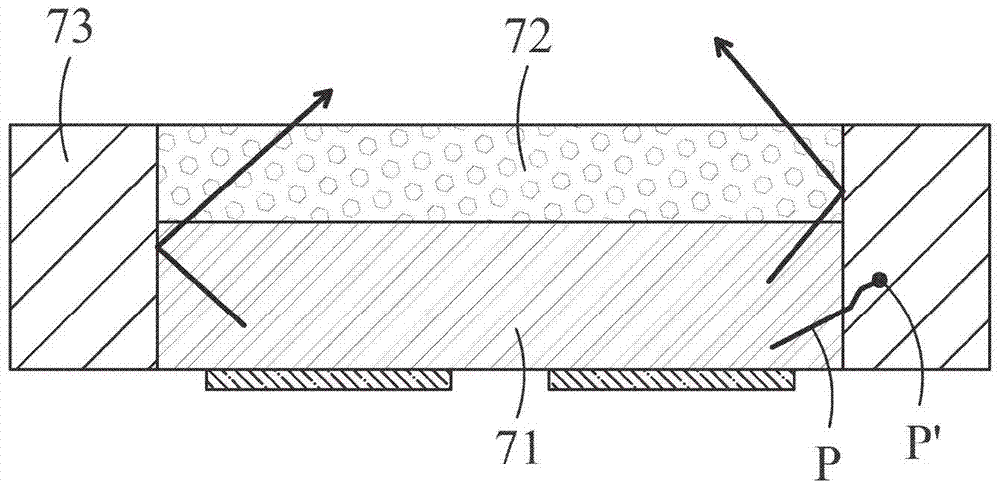

[0070] see Figure 2A and 2B As shown, it is a perspective view and a full cross-sectional view of a light emitting device 1A according to a first preferred embodiment of the present invention. The light emitting device 1A may include an LED chip 10, a fluorescent structure 20, a beamshaping structure (or BSS for short) 30 and a light-transmitting structure 40, and the fluorescent structure 20, the BSS 30 and the light-transmitting structure 40 A light-transmitting packaging structure 200 can also be formed; the technical content of the multiple components will be described in sequence as follows.

[0071] The LED chip 10 is a flip-chip LED chip, which includes an upper surface 11 , a lower surface 12 , a vertical surface 13 and an electrode group 14 . The upper surface 11 and the lower surface 12 are oppositely disposed, and the vertical surface 13 is formed between the upper surface 11 and the lower surface 12 and connects the upper surface 11 and the lower surface 12 . I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com