Fragile transverse plane grinding machine used for rock test

A technology of rock testing and end face grinding, which is applied in the field of rock mechanics testing to achieve the effects of simple structure, reduced probability of collapse, and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

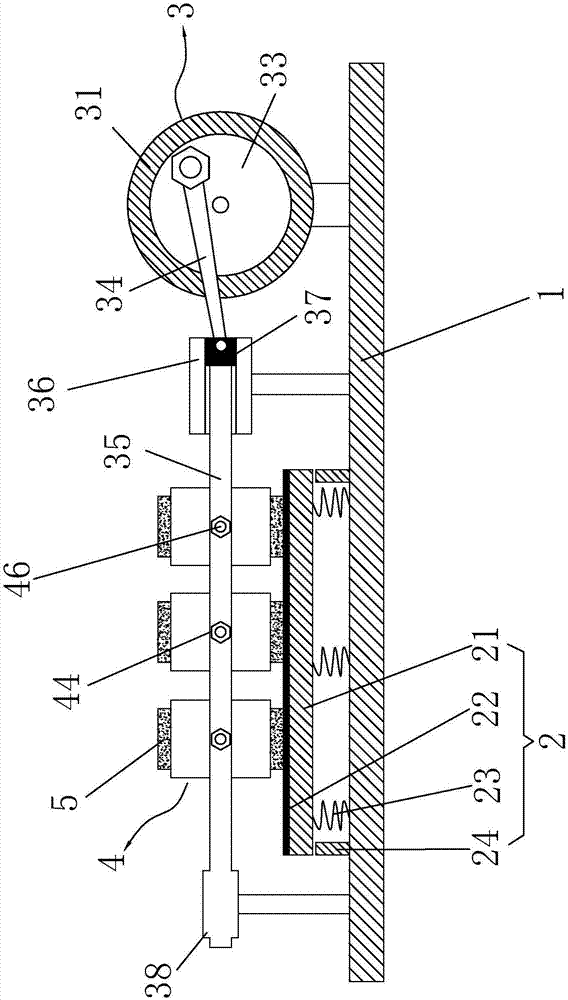

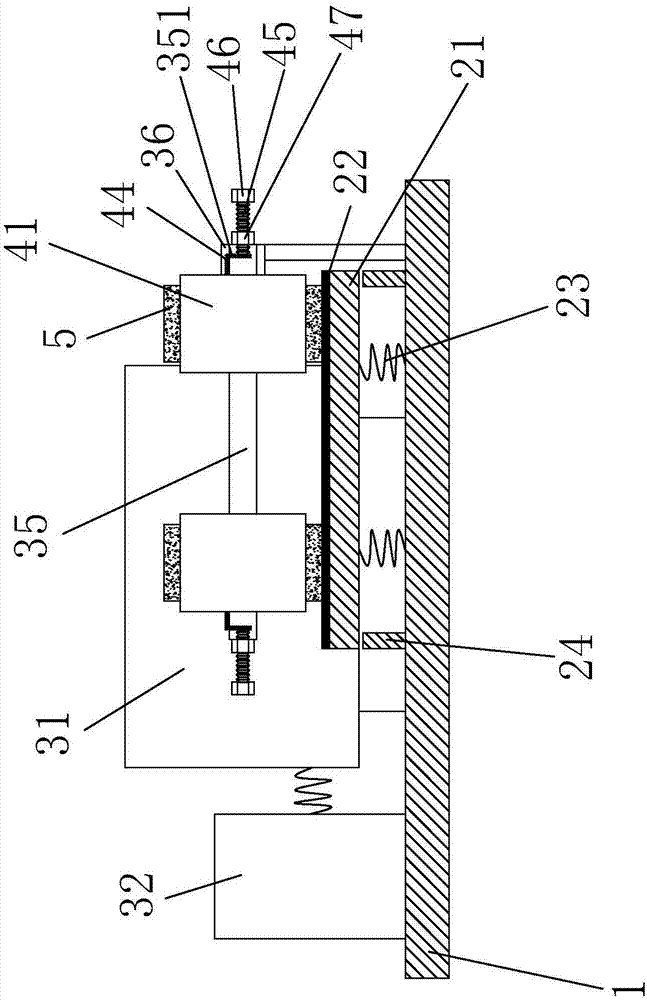

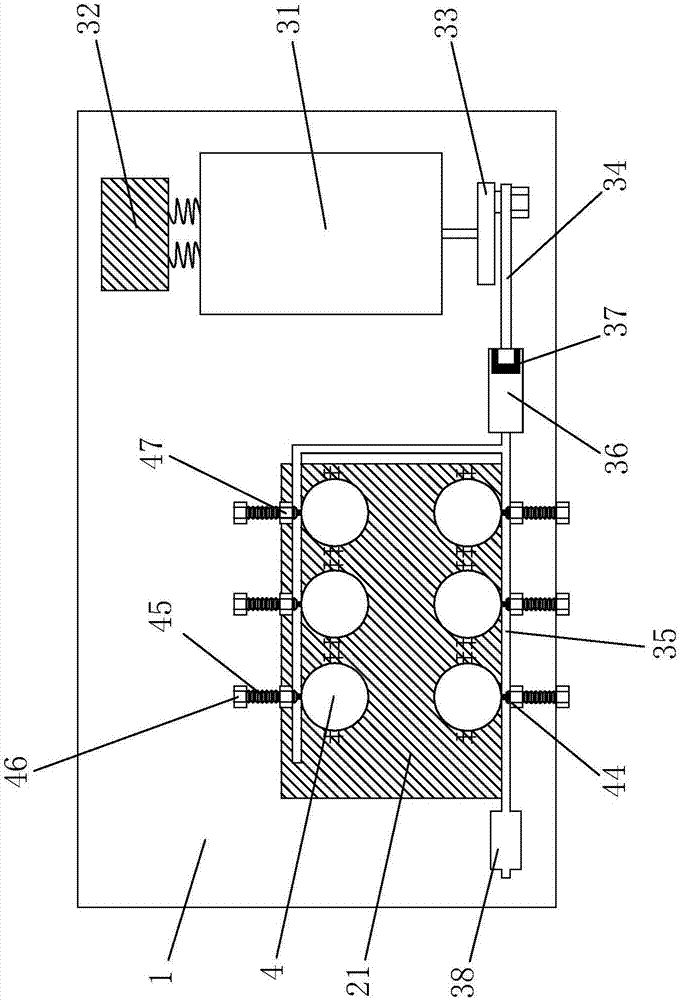

[0042] With grinding length 100mm, the standard coal rock rock sample of diameter 50mm is example, illustrate that the specific embodiment of the present invention is as follows:

[0043] (1) Replace the rock clamping mechanism 4 that meets the test standard specifications, place the standard rock sample in the rock clamping mechanism 4, and give the workbench 21 a downward initial force, so that the lower spring 23 is in a slightly compressed state, and work The four corners of the table 21 all touch the stoppers 24. At this time, adjust the position of the end face of the rock sample and the workbench 21 to ensure that the end face of the rock sample is in strong contact with the sandpaper 22 on the workbench. Tighten the first moving nut 433 and the second moving nut 47 to fix the Rock samples, to prevent the rock samples from loosening and damaging the rock samples during grinding.

[0044] (2) Press the power button, the smoothing machine starts to work, and the speed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com