A Load Calculation and Loading Method of the Cutting Head of a Virtual Prototype of Longitudinal Axis Tunneling Machine

A virtual prototype and load calculation technology, applied in calculation, cutting machinery, earthwork drilling and mining, etc., can solve the problems of load nonlinear impact and strong coupling, and achieve accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

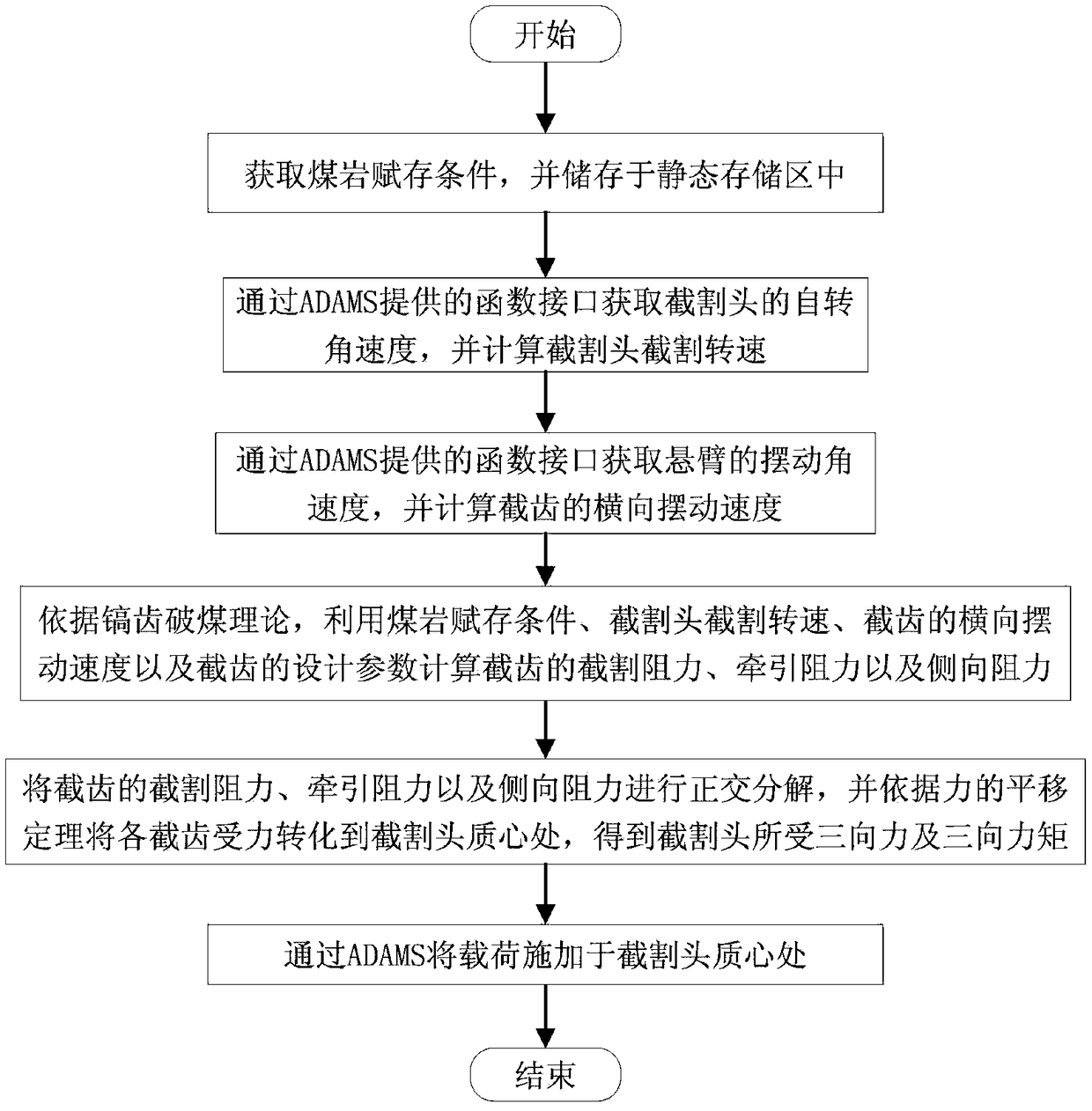

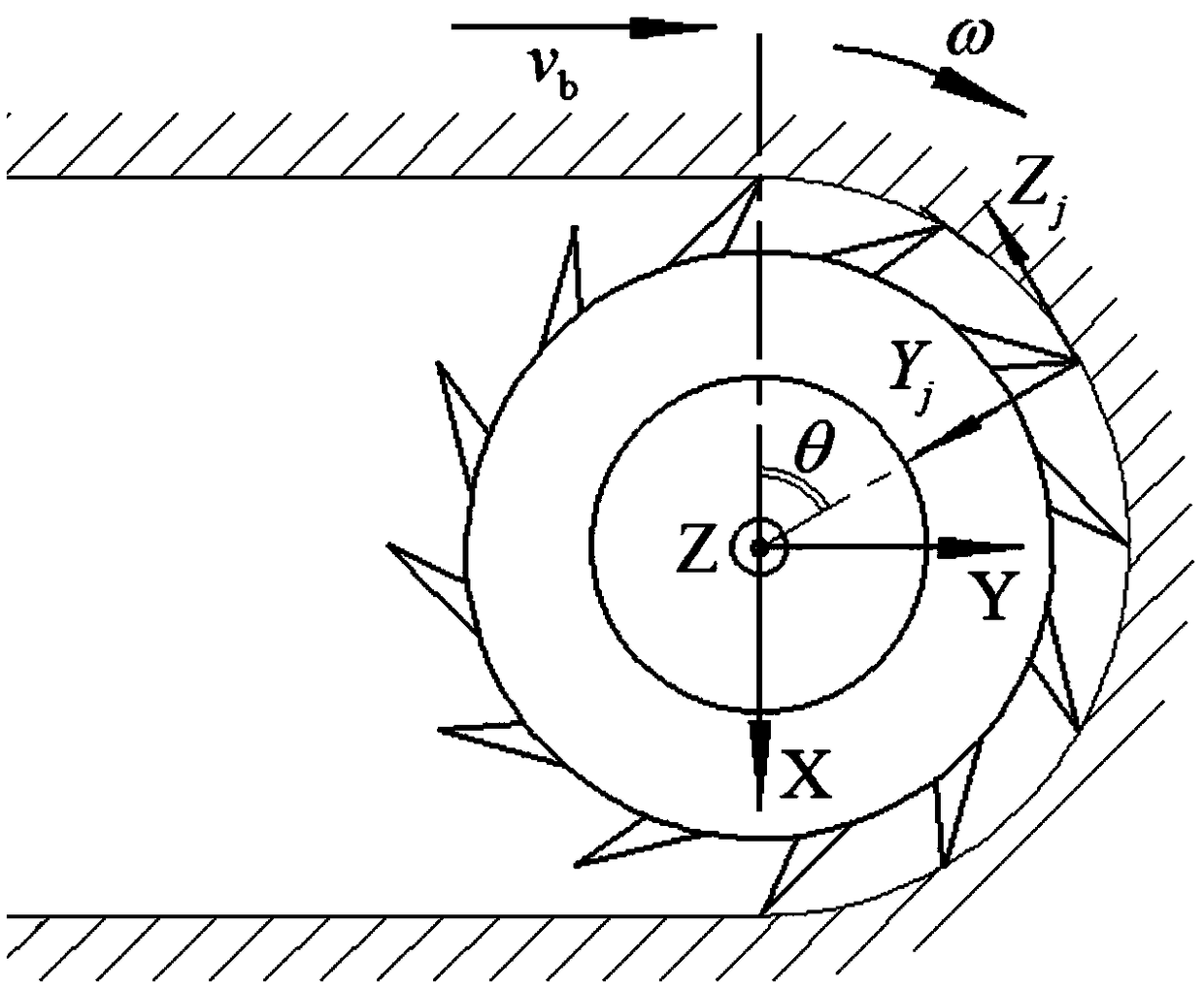

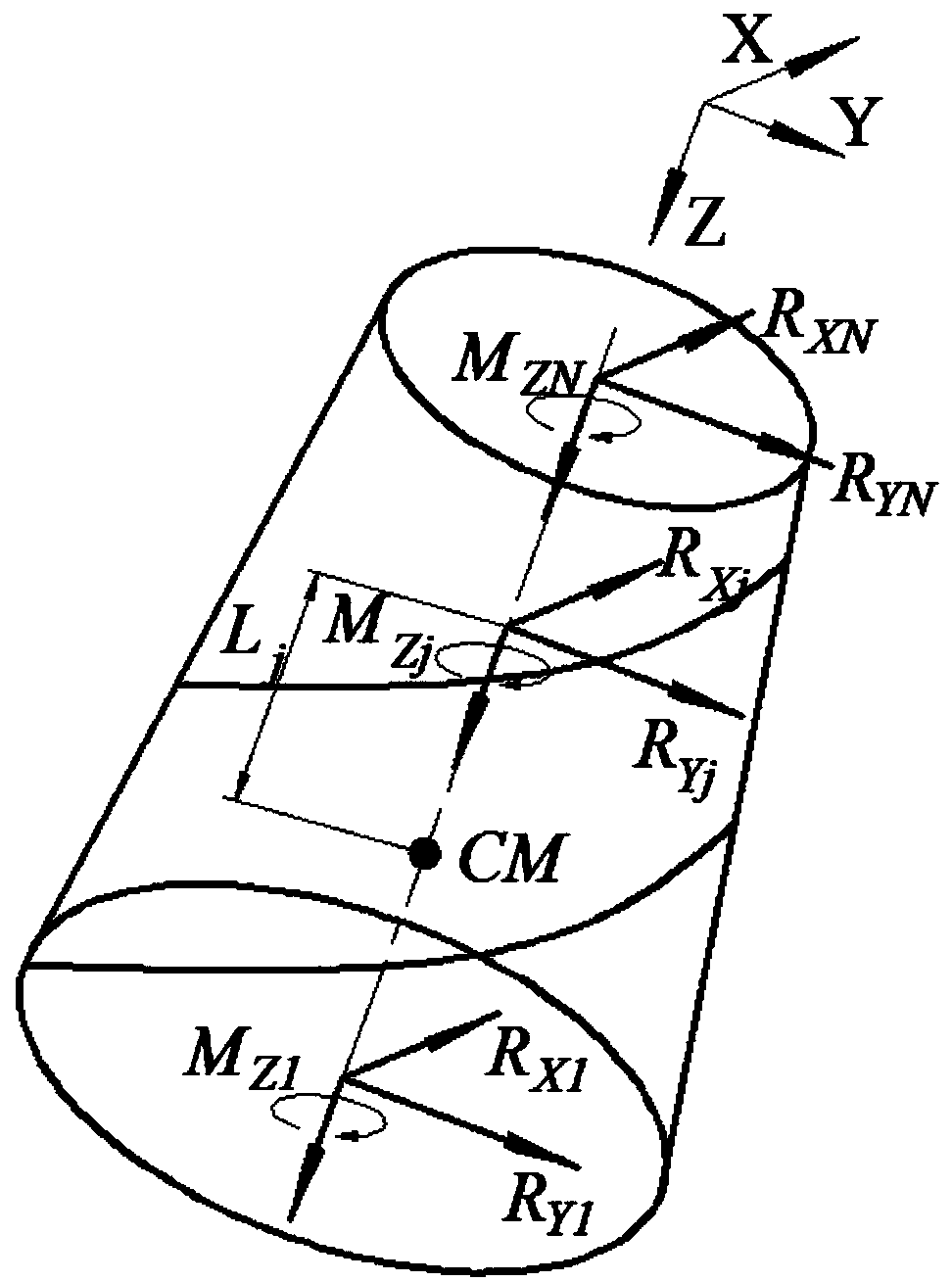

[0031] In this embodiment, if figure 1 As shown, a method for calculating and loading the cutting head load of a virtual prototype of a longitudinal-axis roadheader includes the following steps:

[0032] Step 1: Obtain coal and rock occurrence conditions and store them in the static storage area;

[0033] The coal and rock occurrence conditions include coal occurrence conditions and rock occurrence conditions, and the coal occurrence conditions include the average value of coal seam cutting resistance, coal brittleness coefficient, and mine pressure influence coefficient in non-ground pressure affected areas. , the uniaxial compressive strength of the coal and the coefficient of coal under compression; the occurrence conditions of the rock include the rock contact strength.

[0034] Step 2: Obtain the rotation angular velocity of the cutting head t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com