Inductor component

A technology for inductors and components, applied in the field of inductor components, can solve the problems of reduced installation stability of inductor components, unstable posture of inductor components, and small volume of magnetic complexes, and achieves suppression of volume reduction, posture stability, The effect of improving installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

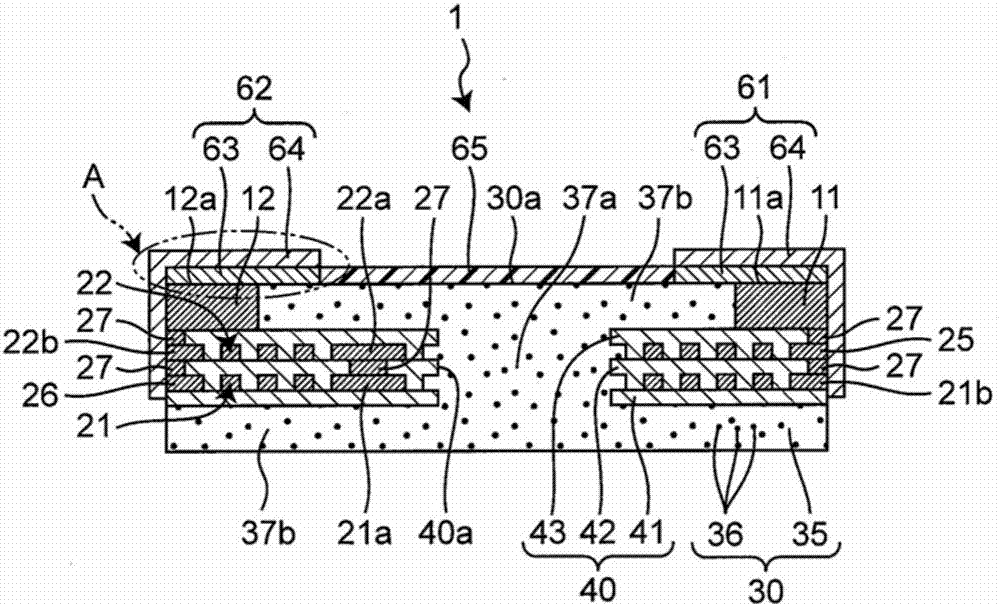

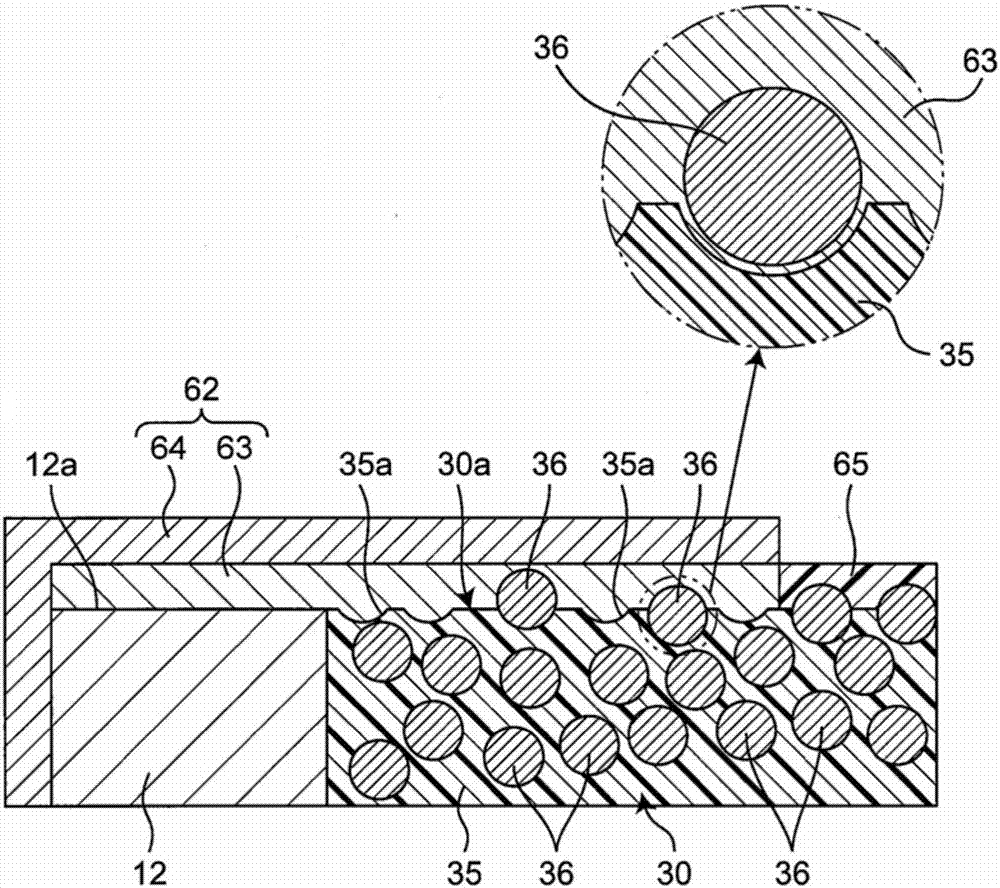

[0064] figure 1 It is a sectional view showing the first embodiment of the inductor component of the present invention. In addition, the drawings are schematic diagrams, and the scale and relationship of dimensions of components may differ from actual ones. The inductor component 1 is mounted in electronic devices such as personal computers, DVD players, digital cameras, TVs, mobile phones, and automotive electronics, for example, and has a rectangular parallelepiped shape as a whole. However, the shape of the inductor component 1 is not particularly limited, and may be a columnar shape, a polygonal columnar shape, a conical trapezoidal shape, or a polygonal pyramidal trapezoidal shape.

[0065] Such as figure 1 As shown, the inductor component 1 has multilayered spiral wirings 21 and 22 , an insulator 40 including multilayered insulating layers 41 to 43 alternately laminated with the multilayered spiral wirings 11 and 12 , and a magnetic composite covering the insulator 4...

no. 1 example

[0115] Examples of the first embodiment will be described. The inductor part is used as a step-down switching regulator with a switching frequency of 100MHz. It is a power inductor with a size of 1mm×0.5mm and a thickness of 0.23mm. The number of turns of the spiral wiring is 2.5 turns in a double-layer structure, and the inductance value is approximately 5nH at 100MHz.

[0116] The number of turns of the spiral wiring is set so that the desired inductance value can be obtained in accordance with the switching frequency. For the switching frequency of 40MHz to 100MHz, set it to be less than 10 turns.

[0117] Although the spiral wiring shows an example where L / S / t=70 / 10 / 70 μm, L and t are set according to the chip size and the allowable current energized in the inductor. The interlayer pitch of each spiral wiring is the same as the wiring pitch of 10 μm. By making the wiring pitch and interlayer pitch of the spiral wiring very narrow to 10 μm or less, the spiral wiring can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com