Rainwater pipeline cable

A pipeline optical cable, rainwater technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of poor corrosion resistance, rodent and termite resistance, cable damage, resource waste, etc., to achieve good water resistance and moisture resistance, and ensure use Longevity, enhanced tensile properties and effects of biodamage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

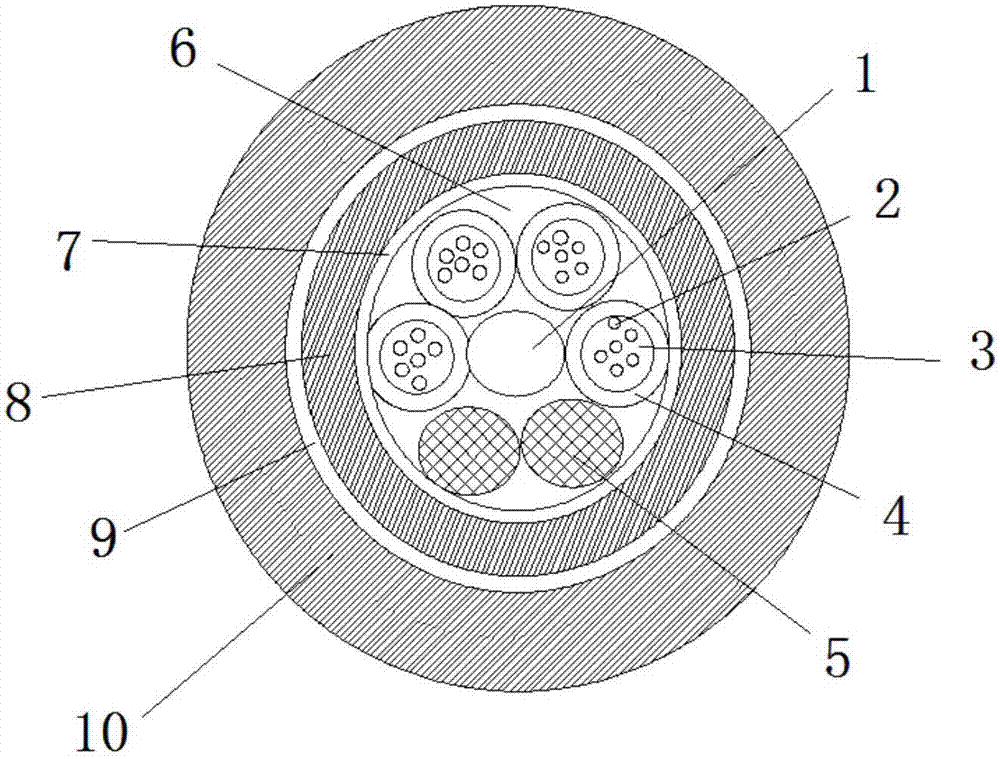

[0022] Such as figure 1 As shown, this specific embodiment adopts the following technical scheme: it includes a central strength member 1, an optical fiber 2, a fiber paste 3, a plastic loose tube 4, a filling rope 5, a cable paste 6, an aluminum-plastic composite tape 7, and a polyethylene sheath 8. Aramid yarn layer 9 and polyethylene sheath 10, several plastic loose tubes 4 are twisted around the central reinforcement 1, each plastic loose tube 4 is equipped with optical fiber 2 and filled with fiber paste 3, the aluminum The plastic composite tape 7 is coated on the outside of the plastic loos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com