Magnetic and force cilium bionic sensor and preparation method thereof

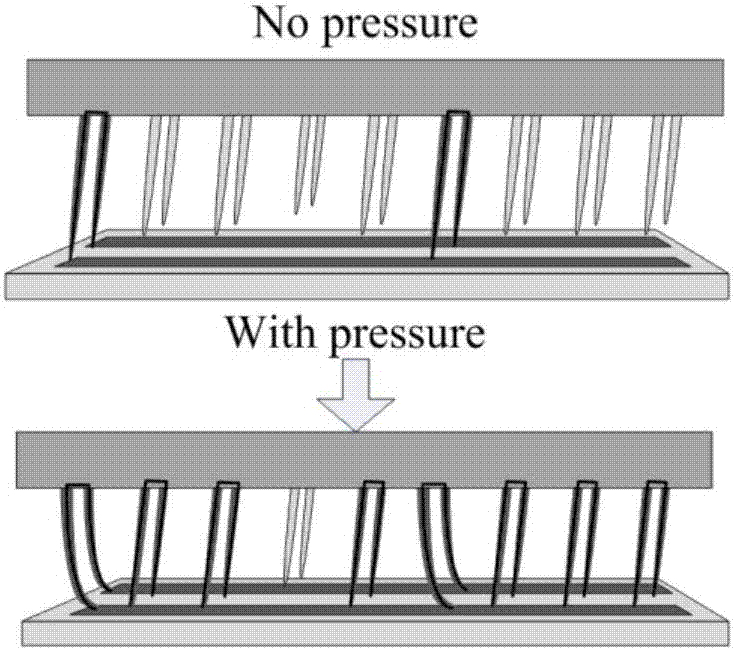

A sensor and cilia technology, applied in the field of flexible sensors, can solve problems such as detecting a single contact force signal, and achieve the effects of good repeatability, low cost and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

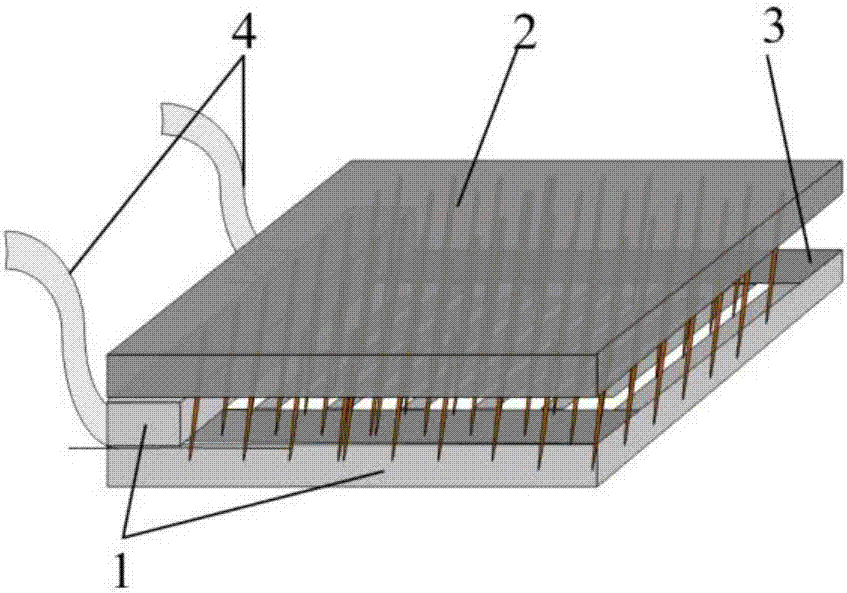

[0039] Step 1. Add 1.5g of polydimethylsiloxane and 0.2g of cobalt particles with a diameter of 500nm into 15ml of ethyl acetate and stir evenly. After ultrasonication for 0.5min, quickly put the above mixed solution in a 300mT uniform vertical magnetic field environment. Heating at 60°C for 16 hours until the solvent is completely volatilized and the resin is cured to obtain a magnetic cilia array, such as Figure 4 shown.

[0040] Step 2: Soak the above-mentioned magnetic cilia array in a graphene oxide aqueous solution with a concentration of 0.2g / L for 5 minutes, take it out, put it in a uniform vertical magnetic field environment, and heat it at 60°C for 4 hours until it is completely dried.

[0041] Step 3. Put the above-mentioned magnetic cilia array coated with graphene oxide into HI solution, soak at 20°C for 3min, wash with deionized water, and then heat at 60°C for 2h to completely dry to obtain the surface covered with reduced graphite oxide The magnetic cilia arr...

Embodiment 2

[0046] Step 1. Add 2g of polydiethylsiloxane and 0.02g of iron particles with a diameter of 500nm into 20ml of xylene and stir evenly. After ultrasonication for 10 minutes, quickly put the above mixed solution in a uniform vertical magnetic field environment of 500mT. Heating under the conditions for 12 hours until the solvent is completely volatilized and the resin is cured to obtain a magnetic cilia array with a cilia length of 1000 μm.

[0047] Step 2: Soak the above-mentioned magnetic cilia array in a graphene oxide aqueous solution with a concentration of 0.5 g / L for 1 min, take it out, put it in a uniform vertical magnetic field environment, and heat it at 80° C. for 2 h until it is completely dried.

[0048] Step 3. Put the above-mentioned magnetic cilia array coated with graphene oxide into KOH solution, soak at 90°C for 60min, wash with deionized water, and heat at 100°C for 0.5h to completely dry to obtain the surface covered with redox Graphene's array of magnetic c...

Embodiment 3

[0053] Step 1. Add 0.5g of polymethylvinylsiloxane and 0.25g of nickel particles with a diameter of 1000nm into 50ml of toluene and stir evenly. After ultrasonication for 10min, quickly put the above mixed solution in a uniform vertical magnetic field environment of 1000mT. It was heated at ℃ for 20 h until the solvent was completely volatilized and the resin was solidified to obtain a magnetic cilia array with a cilia length of 10000 μm.

[0054] Step 2: Soak the above-mentioned magnetic cilia array in a graphene oxide aqueous solution with a concentration of 0.05g / L for 10 minutes, take it out, put it in a uniform vertical magnetic field environment, and heat it at 80°C for 2 hours until it is completely dried.

[0055] Step 3, repeat step 2 5 times.

[0056] Step 4. Put the above-mentioned magnetic cilia array coated with graphene oxide into hydrazine hydrate solution, soak at 60°C for 600min, wash with deionized water, and then heat at 70°C for 1h to completely dry to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com