Self-force-increasing type electronic-mechanic brake for automobile

A technology of mechanical brakes and automotive electronics, applied in the direction of brake types, axial brakes, brake components, etc., can solve problems such as large structural size, difficult installation, lack of automatic gap adjustment function, etc., to ensure stability and consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

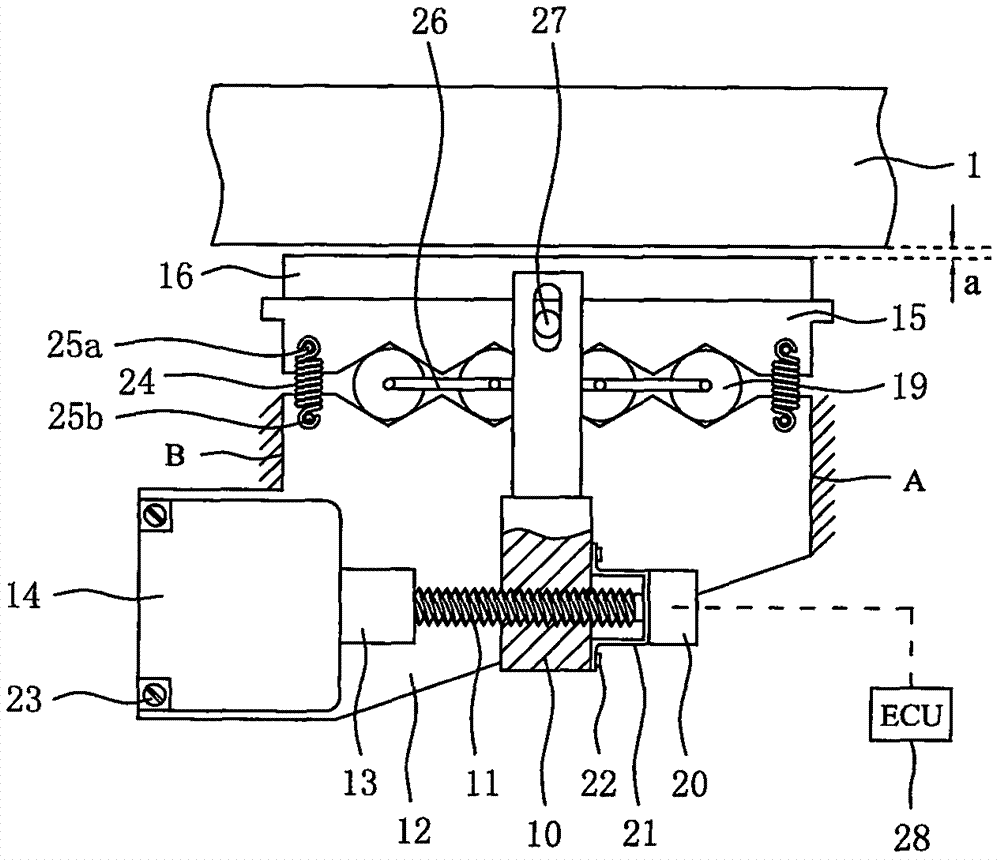

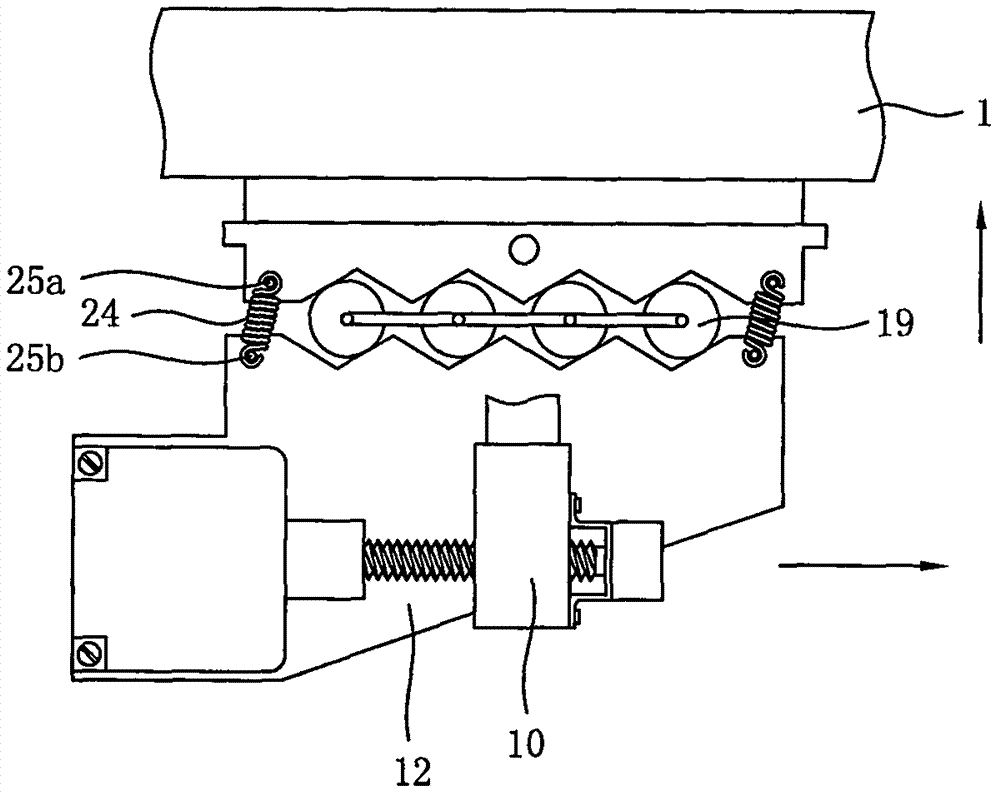

[0021] In the figure, the self-energizing type automotive electromechanical brake of the present invention consists of a brake disc 1, a brake caliper frame 2, a motor 2, a dust cover 4, a guide rod 5, a fixing screw 6, a coupling 2 7, a roller 8. Back plate 9, push rod 10, screw one 11, lower wedge fast 12, coupling one 13, motor one 14, upper wedge fast 15, lower friction plate 16, upper friction plate 17, brake caliper body 18, Roller 19, angle sensor 20, cage 21, screw two 22, screw one 23, tension spring 24, pin one 25a, pin two 25b, connecting frame 26, slide pin 27, ECU control unit 28, screw three 29, Screw rod two 30, adjusting wedge fast 31 form.

[0022] Both sides of the brake disc 1 are provided with an upper friction plate 17 and a lower friction plate 16, and the upper friction plate 17 is fixedly mounted on the brake caliper body 18; the brake caliper body 18 is installed on the brake caliper frame through the guide rod 5 2, can move axially on the guide rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com