Inner and outer cover side sliding and flushing sliding door device

A sliding door and sliding door technology, applied in the field of sliding doors, can solve the problems of clothes hanging in the clothes hanging area hindering sliding, easy accumulation of dust, dust entering the cabinet, etc. The effect of wasting space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

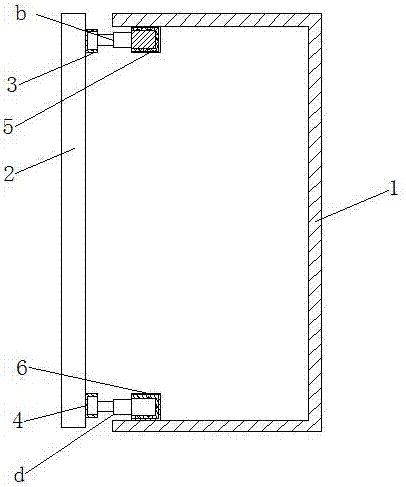

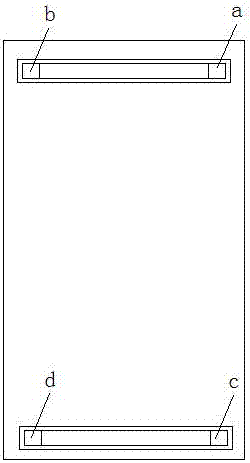

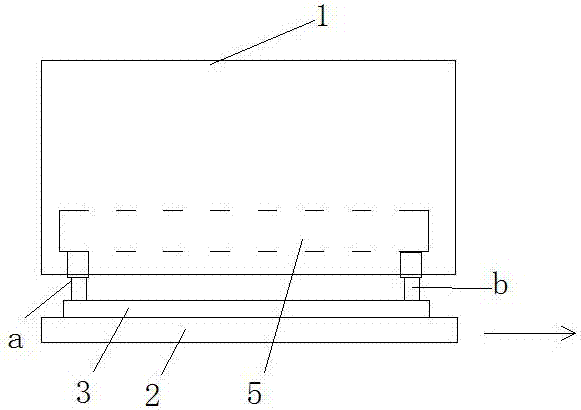

[0026] like Figure 1 to Figure 4 Shown:

[0027] A side-sliding sliding door device with inner and outer covers, including a cabinet body 1, a sliding door 2, connecting sliders (a, b, c, d), an upper chute 3 installed on the upper end of the inner wall of the sliding door 2, an installation The sliding door glide groove 4 at the lower end of the inner wall of the sliding door, the cabinet upper chute 5 installed on the top of the cabinet body and the cabinet body glide groove 6 installed at the bottom of the cabinet body, the upper chute 3 of the sliding door and the upper sliding groove of the cabinet body The groove corresponds to setting 5, and the sliding door sliding groove 4 corresponds to the cabinet sliding groove setting 6;

[0028] The upper chute 3 of the sliding door and the upper chute 5 of the cabinet body are respectively connected by connecting sliders (a, b), and the sliding door glide groove 4 and the glide groove 6 of the cabinet body are also connected b...

Embodiment 2

[0037] like Figure 7 As shown, a side-sliding and parallel sliding door device with inner and outer covers, including a cabinet body 1, and 3 sliding doors (e, f, g), wherein, in the sliding door f, one end of the connecting slider b is fixed to the sliding door One end of the upper chute and the other end are slidingly set in the upper chute of the cabinet body; one end of the connecting slider d is fixed on the sliding door sliding groove, and the other end is slidingly set in the sliding groove of the cabinet body; one end of the connecting slider a slides It is installed at the other end of the upper chute of the sliding door, and the other end is fixedly installed in the upper chute of the cabinet body; one end of the connecting slider c is slidably arranged at the other end of the sliding groove of the sliding door, and the other end of the connecting slider c is fixedly installed with the cabinet body In the sliding groove, the sliding door f can slide to the left this...

Embodiment 3

[0039] The sliding door can be set in the cabinet as an inner cover door, which can be pushed inside when opening, and then slide to open from the inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com