Wire cable connector for tension stringing of transmission line

A technology for tension stringing and transmission lines, which is applied to the installation of cables, overhead lines/cable equipment, electrical components, etc. It can solve problems such as unreasonable body structure, small safety factor of connection points, broken connectors, etc., to improve Effects of safety margins, optimized cross-sections, and relaxed dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

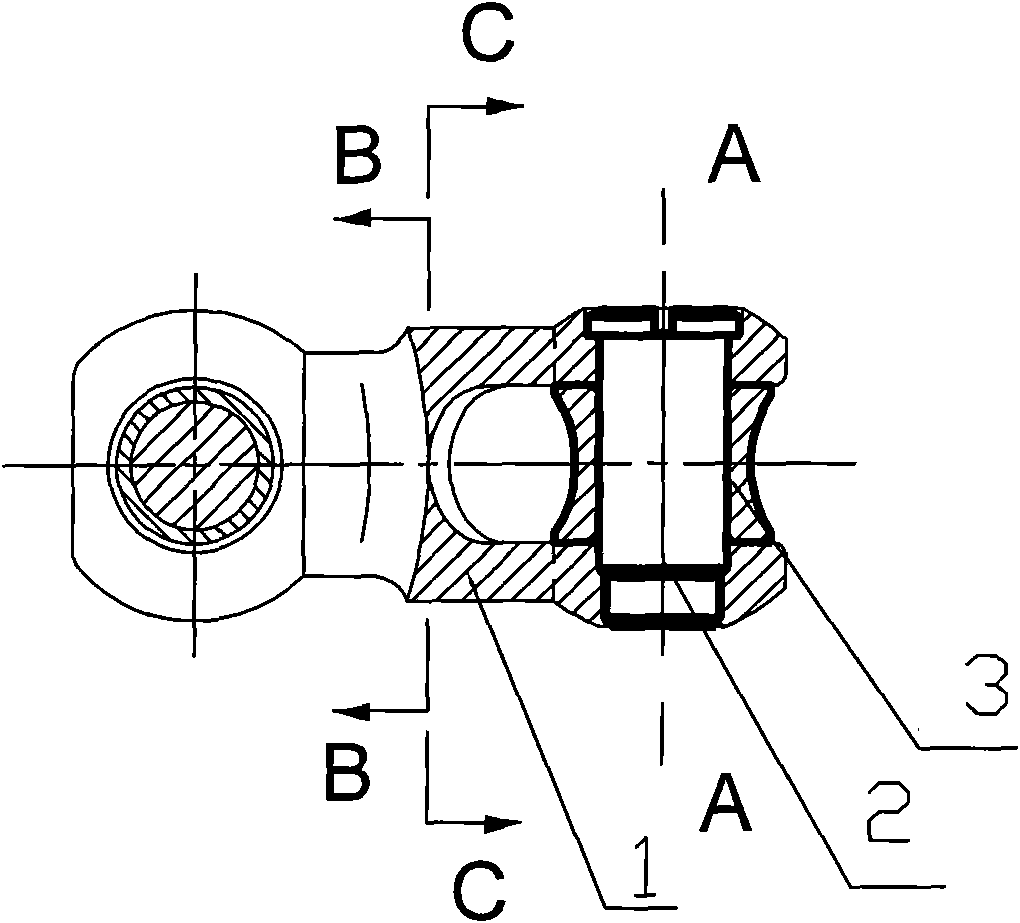

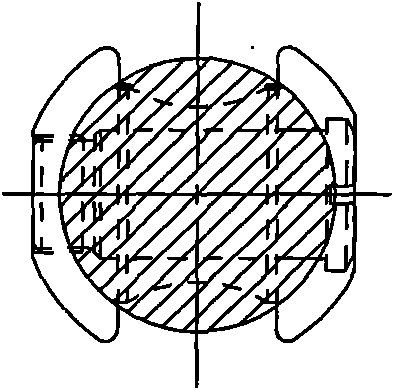

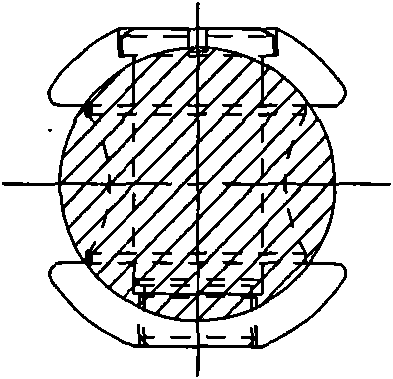

[0013] A steel cable connector used for tension stringing of power transmission lines, including a bending-resistant body 1, a cylindrical head screw pin 2 and a sheath 3, the middle of the bending-resistant body is a cylinder, and the two ends are connected to mutually symmetrical spheres, The diameter of the sphere is greater than the diameter of the middle cylinder, the bottom of the opening grooves at both ends of the anti-bending body is arc-shaped and the positions of the two openings are staggered by 90°, the sheath and the anti-bending body are connected together by cylindrical head screws .

[0014] The sphere is symmetrical with the central plane of the opening groove and the plane perpendicular to the central plane and passing through two central points, and the surroundings of the sphere are respectively symmetrical planes.

[0015] The sphere can be replaced by other symmetrical shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com